Injection Machines Use Novel Two-Stage Molding System

EdeX servohydraulic presses from Taiwan are the first to employ the Inject-EX plasticating system from Md Plastics.

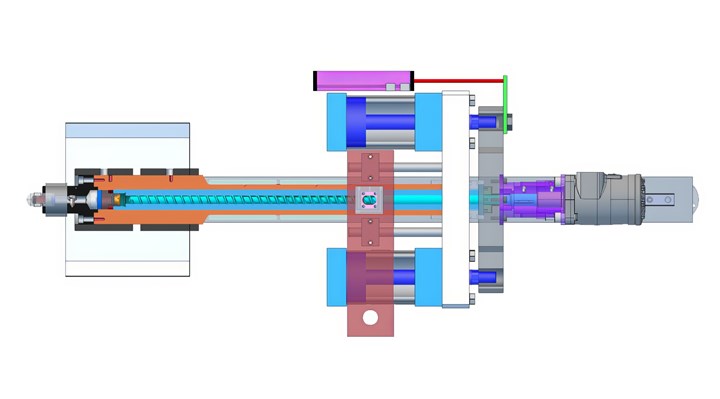

Md Plastics is now marketing special Inject-EX versions of servohydraulic, two-platen injection presses from EdeX of Taiwan. (Photo: EdeX Technology Co.)

At NPE2018, Md Plastics showed off the prototype of a novel inline screw/plunger system called Inject-EX, designed to overcome the limitations of standard reciprocating-screw injection molding machines. Since then, the design has evolved, with an improved heating system and, most importantly, a Taiwanese machine builder has adopted the Inject-EX system for a series of presses to be marketed here by Md Plastics.

New Two-Stage Design

As stated by Michael Durina, president of Md Plastics, the Inject-EX plasticating system was developed “to ensure that each pellet is exposed to the exact same amount of energy during its journey from the hopper to the mold. The result is a melt that is more uniform and homogeneous than is produced by today’s reciprocating-screw systems.” He explains that as the conventional reciprocating screw retracts during recovery, the pellets entering the feed throat are exposed to a continuously changing L/D, so their shear exposure is inconsistent, which leads to viscosity variation. That effect is exacerbated by the fact that when the screw moves forward during injection, pellets fall from the hopper into the empty screw flights. Those pellets are not compacted efficiently during the next recovery cycle, creating further melt variability. Add to these problems the well-known issue in conventional machines of inconsistent shot volume due to inconsistent closing of the check valve at the end of the screw at the start of injection.

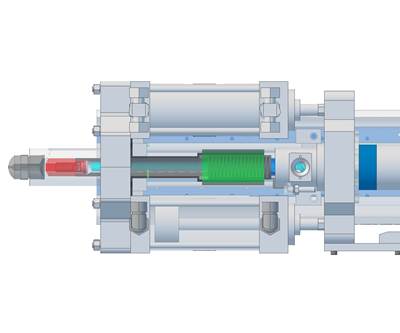

Inject-EX machines incorporate Md Plastics’ inline two-stage injection unit, in which the fixed screw feeds melt through an inner channel in the center of the coaxial plunger to accumulate in front of the plunger. The entire screw/plunger assembly moves forward to inject and backward to recover the next shot. (Image: Md Plastics)

All these problems can be reduced or eliminated with two-stage screw/plunger systems, of which Inject-EX is a new variant. Like other two-stage systems, this one has a plasticating screw (Md Plastics’ Posi-Melt design) that is stationary with respect to the feed hopper and that feeds an injection plunger via a shutoff valve. What’s different about Inject-EX is that the screw and plunger are not housed within separate cylinders, but are directly coupled inline. The screw feeds melt through a channel or “inner barrel” in the center of the injection plunger, and the melt exits that channel at the front of the plunger. The valve between the screw and plunger sections is the same one used in Md Plastics’ Mini-Shut shutoff nozzle. This is a poppet valve that is spring loaded with Belleville washers. It therefore shuts immediately when the screw stops turning. This design provides true “first-in/first-out” melt inventory, unlike most other two-stage designs.

Also unique to this system, the entire screw/plunger barrel assembly moves forward to inject, emptying the melt chamber in front of the plunger through a Mini-Shut shutoff nozzle on the end of the barrel. This design is said to be simpler, more compact, and less costly than other two-stage designs.

Novel inline screw and plunger are designed to overcome limitations of conventional reciprocating screws, in a system more compact and less costly than other two-stage configurations.

New Machine Series from Taiwan

Md Plastics, a supplier of screws, check valves, shutoff nozzles and other plasticating components, is now marketing its first injection press, built by EdeX Technology Co., Ltd. in Taiwan. EdeX (edex.com.tw) is a privately owned firm started in 2009, which builds around xx injection machines a year. It is mounting Inject-EX plasticating systems on a selection of press sizes from its ATOM and ATOP series of CE-certified, servohydraulic horizontal presses (see accompanying table). These are space-saving two-platen designs with four platen-mounted clamp cylinders, air-cooled hydraulics and INV7800A controls with 15-in. screen from LNC Technology Co., Ltd. (lnc.com.tw) in Taiwan. The company has built two-stage machines before, with an angled screw above the plunger barrel, a design used by a number of injection machine builders. A 70-metric-ton EdeX machine with Inject-EX system is newly arrived at Md Plastics’ plant in Columbiana, Ohio.

While the EdeX models initially offered by Md Plastics are designed for thermoplastics, Durina hopes to offer LSR versions in the future. (An Inject-EX system for LSR was shown at NPE2018). “They won’t need a screw at all,” Durina says. “The silicone material can feed directly into the inner barrel of the injection plunger where the end of the screw would normally be. And we can put a static mixer at that entry point, so there would be no need to premix the two LSR components in the feed system.”

Durina also notes that the EdeX machines being sold here are built with provisions to accept Md Plastics’ special Temp-Sense melt-temperature sensor and the latest version of the Melt Profiler melt-temperature control system, called Melt iQ.

Related Content

New LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

Read MoreSilicone Elastomer Course Returns

After completely filling the classroom last year, the Silicone Elastomers Technology and Fabrication course returns to Pomona, Calif. Jan. 31-Feb. 3.

Read MoreBeacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreRead Next

Injection Molding: Novel Injection Unit With In-Line Screw/Plunger

Md Plastics has a new injection unit designed to overcome longstanding limitations of reciprocating screws.

Read MoreInjection Molding: Making Melt Temperature A Useful Tool for Process Control

Portable, standalone data monitor replaces a laptop. Newest system uses melt thermal data to signal injection fill-to-pack switchover.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

(2).jpg;maxWidth=300;quality=90)