Why Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

One of the terms you hear talked about is the compression ratio of a screw. Some have assumed the compression ratio is designed just with feeding in mind. Not so. The compression ratio has to be established not just to feed enough solid polymer to fill the screw, but also to introduce enough shear heating in the screw to complete melting. There are quite a number of variables that go into selecting the proper compression ratio. I find that most designs don’t really consider many of them, so it truly becomes only a rough estimate.

The compression ratio is simply the ratio of H1 ÷ H2 (feed depth ÷ metering depth) and applies to all screws.

Feeding is the first consideration, which is a balance of particle geometries, friction of the particle to the screw/barrel surfaces (including the feed throat), and the particle-to-particle friction. HMWPE, for example, is usually processed with a grooved barrel section because it is so slippery. Add in the bulk density, angle of repose, particle hardness and melt density, and you are starting to get some of the more influential properties. Even the hopper design has an influence because particle flow governs the filling pressure on the screw. Any “feed assist” device (like a crammer) would change the ideal compression ratio for a low-bulk-density material.

Just as important, shear heating is also a function of the compression ratio, as it determines the shear rates throughout the screw. The greater the “compression” between the feed section and the remainder of the screw, the greater the amount of energy per unit output going into the polymer to complete melting. Every polymer is different in its energy requirement, and you have to consider such things as polymer viscosity at differing shear rates along with specific heat and the ideal exit temperature.

Screw performance is often compromised if you are not considering some of the most influential variables that go into selecting the most effective compression ratio.

Different processes, for example, require different melt temperatures – even with the same polymer. For example, ideal sheet-extrusion and fiber-drawing melt temperatures may vary by 50°F or more. This necessitates balancing the feeding and melting requirements to a certain extent. In other words, there is no ideal compression ratio for a specific polymer without consideration of many other variables. Assuming a certain feed depth of “H,” a 2:1 compression ratio will put approximately half as much energy into the polymer as a 4:1 compression ratio. Again, the screw must be full for optimum melting, which brings in the feed variables.

Technology exists so that all these properties can be considered, but the collection of all the data and its analysis is so complicated that it can only be done with the most advanced computer simulation programs available. As a result, it is simply not done on a regular basis. Compression ratios have been pretty much standardized over the years based on what has typically worked before. For example, PE screws typically use a 3:1 ratio as a starting point, while nylon screws typically start with a 4:1 ratio. This establishes only a starting point and streamlines the design effort, but a lot of screw performance is often compromised if you do not consider some of the most influential variables that go into selecting the most effective compression ratio.

Much wider use of recyclate has made such considerations even more important, as the feeding properties of recycle may conflict with the melting requirements. For example, a low-bulk-density recycle may require more feed depth to fill the screw; yet the “standard” compression ratio for that polymer would result in not enough shear heating. Consequently, the feeding and melting should be determined separately, doing away with the so-called standard compression ratios.

Even more complicated are mixed polymers that are common in some recycling applications. I recently encountered a PP/HDPE mix that took some extra thought, particularly on the melting calculation, which completely changed the compression ratio. The two recycled polymers were different in both their solid properties and energy requirements.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 50 years. He is now president of Frankland Plastics Consulting LLC. Contact; 724-651-9196; jim.frankland@comcast.net.

Related Content

How to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

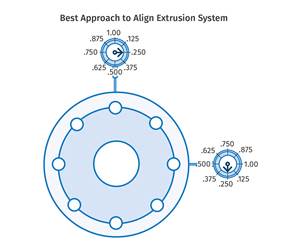

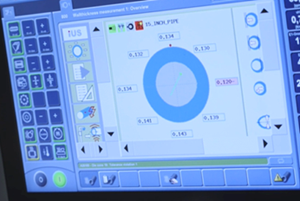

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.jpg;width=70;height=70;mode=crop)