Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

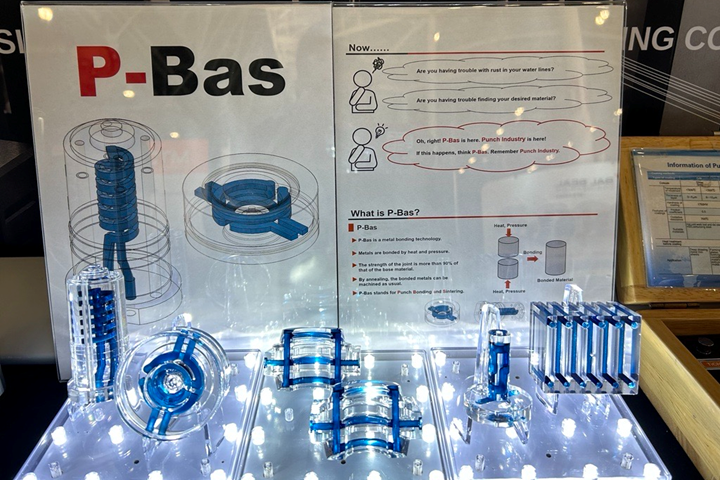

Punch Industry USA Inc. is exhibiting its parent company’s bonding and sintering technology called P-Bas. P-Bas, an alternative to 3D metal printing, is used to fabricate custom conformal cooling channels for mold and die components by bonding split parts, offering an extensive compatibility with iron-based materials. Punch Industry has applied for a patent for this novel technology.

P-Bas, denoting Punch Bonding and Sintering, employs heat and pressure for metal bonding, achieving joint strength surpassing 90% of the base material. Additionally, P-Bas produces parts and cooling lines with a finer, smoother surface finish than that of 3D metal printed parts; the process includes a surface coating to reduce rust formation in the cooling lines.

Parts that can be made using P-Bas include gate inserts for components to make plastic bottles, core pins for injection and die-cast molds, and sprues.

Customers can initiate the P-Bas ordering process by designing components with cooling channels, approving suggested split parts and receiving a quotation. Rigorous testing, encompassing bend tests for joint strength and leak tests for watertight integrity ensures the reliability of P-Bas technology.

Related Content

-

Spiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

-

Auto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

-

Is Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.