Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

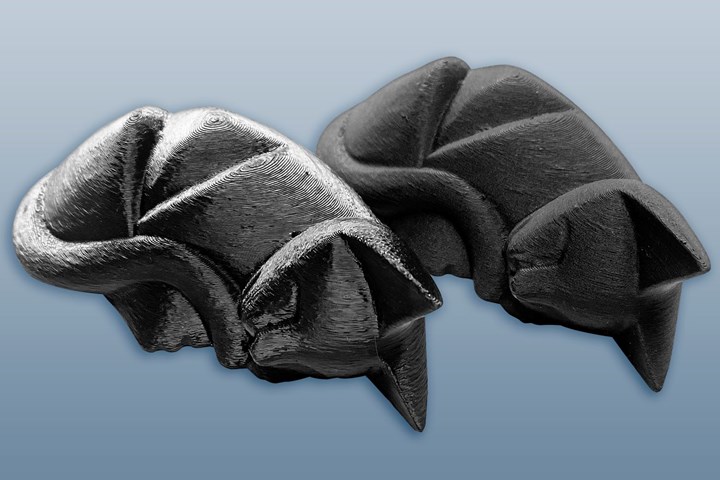

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

Two new low-gloss additive masterbatches for PLA and PETG FDM (fused deposition modeling) 3D printed systems are newly being offered by Insight Polymers & Compounding. Insight LAA112 Low Gloss PLA and Insight TCA112 Low Gloss PETG masterbatches have been shown to reduce gloss and improve the aesthetic profiles of 3D printed objects with minimal to no impact on mechanical properties. (Image: Cat depicted on the right incorporates the low-gloss masterbatch.)

Explains director of operations A.J. Pasquale, “Conventional 3D printed parts with high-gloss accentuate layer-lines and other defects suggesting lack of durability, or prototype and single-use only applications.” Typical use level is 10% to 30%. “Additive manufacturing is now used for producing finished goods rather than prototypes for injection molds. So we facilitate that trend by producing masterbatches that make end-products more aesthetically acceptable to the customer.” With FDM filament being used as the final article and 3D printing now a manufacturing technique, Dr. Pasquale said the resulting piece must be aesthetically 100% good, not 90%.Moreover, FDM and other techniques are accepted now for low volume manufacturing. The 3D-printed part, therefore, must present a high-quality appearance that earns customer acceptance.

While the current low gloss masterbatches are designed specifically for FDM, Insight Polymers can develop materials for SLS (selective laser sintering) and BAAM (Big Area Additive Manufacturing), according to customer interest.

Related Content

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

-

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.