Get the Most From Fiber-Reinforced Thermoplastic Composites Parts

There are five specific areas that designers and manufacturers need to consider to realize the potential of these unique materials.

A staple responsibility for designers at any company is to investigate ways of manufacturing their components more efficiently and economically. Injection molding has proven to be a great choice for part consolidation and more efficient manufacturing when polymeric materials are a viable material. Additionally, when the designer needs to replace metals with polymeric materials, discontinuous fiber-reinforced composites can offer great potential for consolidation and lightweighting, while achieving metal-like performance. However, to fully take advantage of these materials, the designer needs to understand their nature and how their characteristics influence the end performance of the molded product.

Filler Type and Loading Level

While there are many different types of fiber-reinforcing fillers for thermoplastic composites when trying to substitute for metals, the two predominate fiber materials used commercially are glass or carbon. Glass fibers have traditionally been the staple reinforcement for thermoplastic and thermoset materials. Assuming that the glass fibers are properly selected and compounded into the thermoplastic material, the addition of glass fibers increases the potential for augmented material stiffness and part strength.

Figure 1 shows that as the amount of glass fibers is increased, the tensile modulus of the material is increased. However, this chart also highlights that despite the bump in the short-term modulus, the critical transitions — where there are significant changes in modulus of the compounds — are still driven by the base resin or matrix. Therefore, the correct matrix selection is still critical when considering the long-term durability of the resin, or when selecting resins that will encounter varying temperature ranges while in service.

Figure 1 – The short-term modulus of a material increases with higher loadings of glass fibers. Source (all images): The Madison Group

Carbon fiber reinforcement fillers offer the opportunity for designers to improve the expected modulus of their composite materials without using as high of a fiber loading. Figure 2 shows how the addition of a similar amount of carbon fiber results in a higher modulus compared to glass, which can offer unique opportunities for lightweighting with plastics parts.

Generally speaking, carbon fiber is still predominately utilized in thermoset and high-performance thermoplastic materials. Because of this focused use of carbon fibers, it is critical the material supplier ensures the selected carbon fiber is compatible with the base resin or matrix. If the carbon fiber is not compatible with the matrix, the benefits will be diminished. While there is significant investment in expanding the use of carbon fibers into more commodity-grade materials, such as polypropylene, the current opportunities are limited.

Figure 2 – The use of carbon fiber as a reinforcement filler can enable improved stiffness of a material at a lower loading level.

Fiber Orientation

While the addition of glass fibers offers the potential for improved part stiffness, it is also important to understand the improvement is not guaranteed. Composite materials exhibit anisotropic behavior, which means that the stress-versus-strain response of the material is dependent on how the applied load is oriented relative to the reinforcing fibers, as shown in Figure 3. When the load is aligned with the fibers, the material responds in a stiff and strong manner. However, when the load is oriented transverse to the fibers, the material responds in a more compliant and weaker manner. Therefore, when designers are looking to utilize composite materials, they need to pay attention to how the fibers are oriented relative to their applied loads.

Figure 3 – The behavior of thermoplastic composites is dependent on the orientation of the load relative to that of the fiber reinforcement.

When discontinuous fiber-reinforced thermoplastic materials are injection molded, the fiber orientation in the part is variable and controlled by how the material flows in the cavity. Therefore, the part design and, specifically, the injection location (or gate) is a critical decision in the optimization of these components. The fibers are oriented based on how the molten plastic is stretched and sheared during the molding process. When the material is injected quickly, the fibers will tend to exhibit more orientation in the direction of flow, which will result in a stiffer and stronger part that may exhibit more anisotropy. When the material is injected more slowly, the fibers will show less orientation and less anisotropy.

When designing with thermoplastic composite materials, it is important that the designer quickly identify where the gate will be located. Ideally, gate location will be selected to enable a balanced filling pattern of the cavity that also minimizes changes in flow direction within the cavity. Minimizing the changes in flow direction will lead to more consistent fiber orientation within the part, which will enable more consistent mechanical properties of the molded part and can help minimize the part warpage after being ejected out of the mold. Simulation tools like Autodesk Moldflow can be utilized by the designer early on in the design process to help identify which gate locations may yield the desired orientation in the final molded part.

In addition to controlling the fiber orientation in the molded part, the gate location will also dictate where weld lines will form in the part. Weld lines are weak areas in a molded part, where the flow front was split and then rejoined. The fibers do not tend to bridge the interface where the weld line forms, and this results in a much more brittle and weaker behavior. Because of the significant influence on the end-part performance, the designer and OEM should dictate the gate location to ensure their ended design will perform as expected.

Fiber Length

While the addition of fibers can benefit the stiffness and tensile strength of a resin, the material can still show significant variation in the expected mechanical properties, which limits the ability to truly lightweight a structure. Additionally, discontinuous fiber-reinforced materials can show inferior impact performance due to the more brittle nature of the materials. To help address these issues, resin suppliers have invested heavily in developing long-fiber technology, where the fibers integrated into a thermoplastic resin are much longer than traditional fiber-reinforced plastics.

Figure 4 – A long-fiber pellet (top) relative to a short-fiber pellet.

Traditionally, discontinuous fiber-reinforced plastics have fibers with lengths of less than 1 mm in the final molded article. Having such short fibers minimizes their ability to distribute loading across a larger area, and it relies heavily on the interface between the resin matrix and individual fibers. Long-fiber technology starts off with fibers that are generally 10-12 mm in length, which should yield fibers that are 1 mm or longer in the final, molded article (see Figure 4). Having these longer fibers enables them to bridge across one another, which thus permits multiple fibers to support and sustain impact loading much more effectively.

The key to realizing the potential of using long-fiber technology is to try and maintain as much of the original fiber length as possible. Therefore, in addition to paying attention to the gate location and mold-filling parameters, as described above, the molder needs to ensure they are using the proper injection molding equipment to process these materials. Molders will want to use 35-mm screws or larger and apply low back pressure with these materials.

Additionally, the screws should have a low compression ratio to help minimize the breakage of the fibers in the barrel. The barrel tends to be the area where the majority of the fiber breakage occurs in these materials. By paying attention to the screw parameters, molders and OEMs can help protect their investment in these materials and help achieve their design intent of the product.

Fiber Cross-Section and Dimensional Stability

While the fiber technologies described above do yield an improvement in the performance of the end product, they also introduce a unique challenge for molders and toolmakers. That challenge is how to minimize the amount of warpage the part will experience after being ejected out of the mold. During molding, the fibers will act as anchors in the molded product which can minimize the amount of shrinkage the material experiences. However, the exact amount of shrinkage is not uniform in all directions with fiber-filled material. These materials also exhibit anisotropic shrinkage, where the material will shrink less along the fiber and more transverse to the fiber. The physics of this variation are beyond this article, but the end result is that fiber-reinforced materials will shrink at different rates depending on the fiber orientation. This variable shrinkage can also lead to a greater amount of warpage with fiber-filled materials. This is one reason why so much previous emphasis was placed on focusing on the gate location. However, just like the introduction of long-fiber technology, glass fiber and resin suppliers have explored manipulating the shape of the reinforcing fiber to minimize the amount of anisotropy. While many shapes have been explored, the two most predominate shapes used commercially are the traditional cylindrical fibers and a rectangular, flat fiber (see Figure 5).

Figure 5 – Images showing the differences in the flat fiber profile versus the traditional cylindrical fiber profile used in discontinuous fiber-reinforced composites.

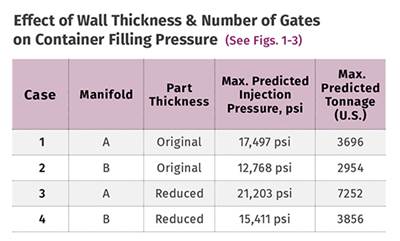

The concept behind the flat fiber is that the level of material shrinkage anisotropy can be reduced without sacrificing performance. Therefore, the use of flat fibers can help reduce the part warpage at a given loading level. There have been many recent publicized success stories of substituting out traditional cylindrical glass fibers with flat fiber cross sections to reduce warp. However, further vetting is still needed. Based upon the author’s experience, the potential benefits of flat fibers are more apparent with thinner wall section parts (See Figure 6). Other benefits such as lower viscosity and therefore lower injection pressures still need to be more thoroughly vetted, but the potential of manipulating the fiber cross section’s geometry seems enticing and is worth bringing up as a new development.

Figure 6 – Application of flat fibers (top part), reduced warp in this application compared to traditional cylindrical fibers (bottom).

Discontinuous fiber-reinforced thermoplastics offer great potential to designers and OEMs as they look to push the envelope with their design and product offerings. However, in order to achieve this potential, the designer and engineers need to take a holistic look at what they are asking of these reinforcing fibers and how they are achieving the desired end result. By paying attention to proper material selection, the molding process and the key characteristics of the reinforcing fibers, that chance for success is greatly increased.

About the author: Erik Foltz is a certified professional Moldflow consultant at the Madison Group. Foltz received his M.S. from the Polymer Engineering Center at the University of Wisconsin. His specialties include plastic part design verification, process optimization and troubleshooting for injection and compression molding, as well as plastics failure. Contact: 608-231-1907; erik@madisongroup.com; madisongroup.com.

Related Content

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

The Long and Short of It (Part 1)—Tips for Molding Long Fiber-Reinforced Polymers

In Part 1 of this series, we address long-fiber processing fundamentals and best practices, including practical tips and guidance on maintaining fiber length and deriving maximum advantages for demanding end applications. Part 2 will provide the same information for short-fiber materials.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read More