Injection Molding and Moldmaking Automation in Focus

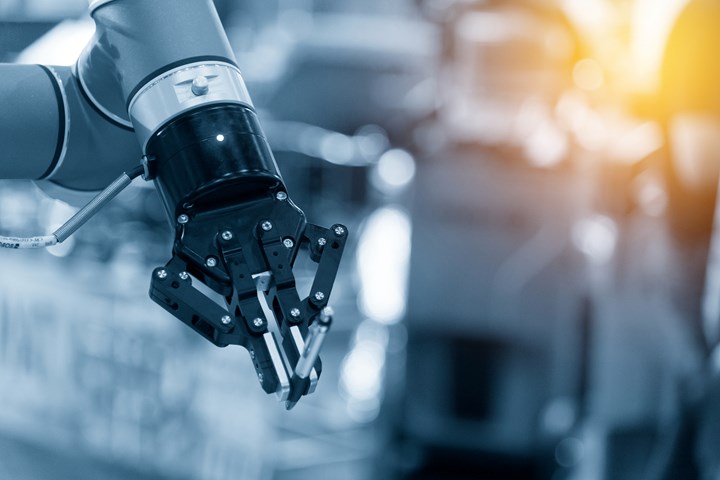

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

Automation of injection molding and moldmaking was framed as essential before the skilled labor shortage exploded, but now, in the face of the yawning skills gap, applying robotics to take on jobs that people are increasingly unwilling to perform is critical to manufacturing’s survival.

At the upcoming collocated Molding and Moldmaking Conferences (August 29-30; Minneapolis, Minn.), multiple presentations will directly address automation in the injection molding and moldmaking industries, giving attendees the opportunity to hear from suppliers and users of automation on and where robotics can be applied.

Automation will be a key topic of multiple presentations at the Molding and Moldmaking Conferences (August 29-30; Minneapolis, Minn.).

Photo Credit: Getty

In the Molding Conference, three suppliers of automation will look at how and when to add automation to the molding floor, in these presentations:

- Is Now the Time to Automate? Cost/Benefit Analysis of Various Automation Applications; Darin Thompson, Wittmann

- Choosing the Right Projects to Automate; Chris Parillo, Yushin America

- Automation — Finding Value, Cutting Waste and Perfecting Process With Simple Robotics; Bill Egert, Logic One

At the collocated Moldmaking Conference (registration to either event grants attendees access to both programs), three leading toolmakers will share their experience with bringing automation into the production of injection mold tooling:

- Using Automation to Solve the “Productivity Puzzle”; Troy DeVlieger, PFAFF Molds

- Choosing Between a “Lights Out” or “Unmanned” Automation Strategy; Louie Fields and Rhonda Lustenberger, Decatur Mold Tool and Engineering

- A Three-Phased Approach to Automation; Tim Galbraith, Cavalier Tool & Manufacturing

Bring your automation questions to Minneapolis and the Moldmaking and Molding Conferences and go back to your facilities with some answers.

Related Content

-

Five Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.