Plastics Additives

Additives are materials that are added to the primary resin during either compounding or processing to improve the polymer’s processability, performance or appearance. Additives include colorants; heat stabilizers; process aids; fillers; compatibilizers; blowing agents; lubricants; slip agents.

ESSENTIAL READING

VIEW ALLUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreWhat’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

Read MorePart 11: A Processor's Most Important Job

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreHow to Prevent Stress Whitening in PP Copolymers

A look at causes, detection, and prevention.

Read MoreExtruding with Fillers

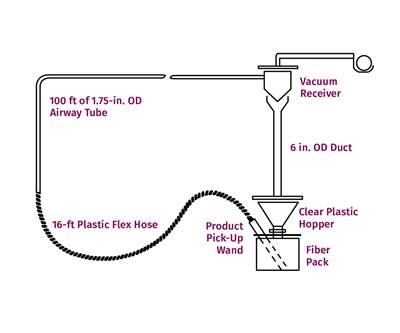

You can use the reference point from processing unfilled polymer to determine whether you can run filled resin on your current system.

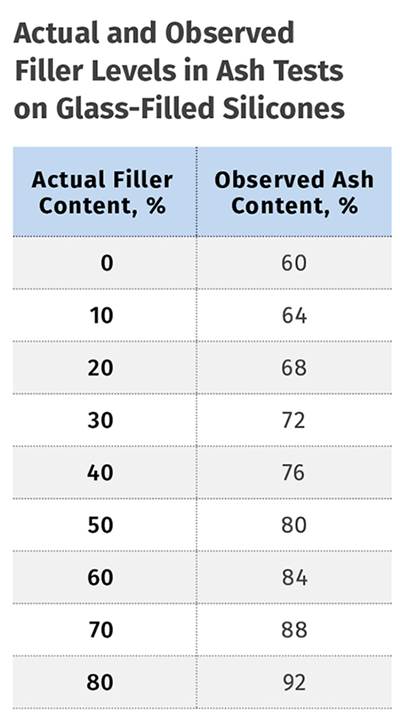

Read MoreMaterials: Analyzing Filler Content

The process is considered simple. But things aren’t always as they seem.

Read MoreLatest Additives News And Updates

Broad Line of Chemical Foaming Agents for Range of Applications

Reedy Chemical Foam’s Safoam RAZ additives are offered in masterbatch and powder blends along with customization.

Read MoreVOC Removal Masterbatch for ABS and PC/ABS Used in EVs

CAI Performance Additives’ VOC Removal Masterbatch LDV 8010 has shown to reduce VOC emissions without compromising product quality.

Read MoreNon-PFAS Mold Release for High-Temperature Polymers

Avient’s Evoluscend is designed to boost manufacturing efficiency.

Read MoreAvient Opens ColorWorks Technology Center in Mexico City

This is the company’s sixth such center aimed at providing technical guidance in plastic product development from its early stages.

Read More‘Game-Changing’ Heat and Light Stabilizer for Agricultural PE Films

BASF’s NOR 211 AR promotes sustainability through reduced polymer usage in the so-called plasticulture — plastics used in agriculture — market.

Read MoreHigh-Jetness Carbon Black for Engineered Plastics

Orion’s new Printex chroma 500 Beads are well suited for applications such as injection molded automotive parts and household appliances.

Read MoreFeatured Posts

Additives Boast Sustainability Without Sacrificing Performance

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

Read MoreStruktol Showcasing a Range of Specialty Additives

NPE2024: Focus is on additives for plastics including PVC and WPC industries.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreRiverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

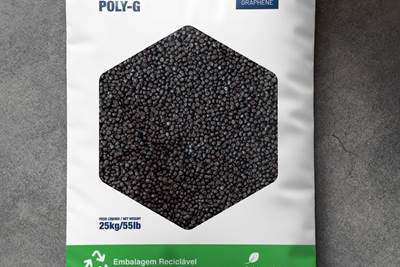

Read MoreGerdau Graphene Launches “First” Graphene-Enhanced PE Additive Masterbatch for Extruded Packaging and More

The company has also partnered with conglomerate Sumitomo Corp. for distribution of its graphene-enhanced masterbatches in Japan.

Read MoreFAQ: Additives

What to consider when adding color?

There are several key items that are essential in developing a colorant package for any polymer. The first of these is the avoidance of any chemical incompatibility between the chemistry of the polymer and the chemistry of the colorant system. Chemical reactions proceed more rapidly at higher temperatures, and melt processing involves significantly elevated temperatures and large inputs of mechanical energy. Therefore, any chemical interactions that may occur between a polymer and a colorant system will happen very rapidly during the injection molding process.

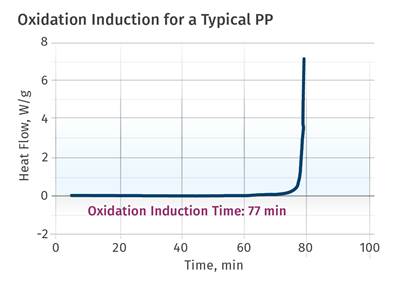

The material supplier will incorporate a certain amount of the stabilization package in the material, making this the starting point for that material. It is now the processor’s job to handle the material during processing so that the molded part contains enough stabilizer to perform to the expectations of the end user. The molding process will always consume some amount of the antioxidant in the material. This is expected. But the amount of stabilizer that is consumed will depend upon the process conditions, most notably the melt temperature and the time the material spends in the molten state. Lower melt temperatures and shorter residence times will produce parts that retain a higher level of stabilization, and these parts will be more capable of handling the application environment. If melt temperatures become elevated or residence times become extended, the molded part will be less capable of managing the application demands.

Additives Supplier Categories

- Additive Manufacturing (3D Printing/Prototyping Materials)

- Antiblocking Agents

- Antioxidant Concentrates

- Fillers--Mineral or Other Inorganic Type

- Processing Aids--Other Organic Types

- Compatibilizers

- Thixotropic Agents

- Biocides

- Color Concentrates, Solid

- Color Concentrates, Liquid or Paste

- Plasticizers

- Processing Aids--Mineral/Inorganic Type

- Crosslinking Agents--Radiation Sensitizers

- Release Agents--External (Spray or Wipe-on)

- Flaw Repair Paint

- Odor Neutralizers

- Antioxidants

- Impact Modifiers

- UV Stabilizers

- Antiblocking Concentrates

- Surface Treatment Chemicals, Dispersion Aids (for Fillers, Pigments, Reinforcements)

- Degradation Promoters

- Reinforcements--Ceramic Fibers

- Metal Deactivators

- Reinforcements--Continuous Fiber Rovings, Tows, Yarns

- Core Materials

- Reinforcements--Carbon or Graphite Fiber

- Fillers--Organic Type

- Cooling-water Treatment Chemicals

- Reinforcements--Mineral Fiber

- Heat-Distortion Modifiers

- Stock Shapes--Rod, Tube

- Blowing Agents--Physical Type

- Reinforcements--Fabric, Mat, Veil, Felt

- Stock Shapes--Film

- Release Agents--Internal (Additive Type)

- Slip Agents

- Blowing Agents--Chemical Type

- Resin Clean-up Solutions

- Viscosity Depressants

- Reinforcements--Aramid Fiber

- Lubricant Concentrates

- Stripping Agents, Resin Removers

- Reinforcements--Nylon, PET or PP Fiber

- Surfactants

- Color Dyes, Pigments

- Purging Compounds

- Processing Aids--Polymeric Type

- Air Release Agents

- Antistat Concentrates

- Flame Retardant Concentrates

- Fillers--Microspheres (Hollow or Solid)

- Flame Retardants/Smoke Suppressants

- Nucleating/Clarifying Agents

- Conductive Additives

- Crosslinking Agents for Thermoplastics

- Blowing Agents--Concentrates

- Lubricants

- Slip Agent Concentrates

- Antifogging Agents

- Heat Stabilizers for PVC

- UV Stabilizer Concentrates

- Desiccant Additives

- Stock Shapes--Sheet

- Fragrance Additives

- Biodegradable, Photodegradable Resins and Compounds

- Reinforcements--UHMW-PE Fiber

- Reinforcements--Glass Fiber

- Antistats

- Reinforcements--Natural Fibers

- Reinforcements--Discontinuous Fibers (Chopped, Milled, Staple)