Biopolymers

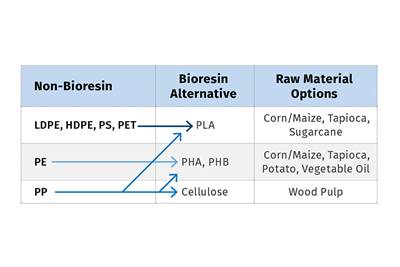

Biopolymers are materials that are generated from renewable natural sources, are often biodegradable and sometimes compostable. PLA; renewable resins; green resins; degradable resins; sustainability.

ESSENTIAL READING

VIEW ALLHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreTracing the History of Polymeric Materials: Polyesters

Beyond PET, PBT and their analogues, development of polyester chemistry led to unsaturated thermosetting resins, copolyester thermoplastic elastomers, liquid-crystal polymers and, most recently, biopolymers.

Read MoreBiopolymer Compounding on a Twin-Screw Extruder: Four Things You Need to Know

Global bioplastic production capacity is expected to increase to 4.8 billion lb by 2024, driven by OEMs and brand owners steadily converting applications to these “green” materials. If you’re looking to supply compounds to meet this demand, here are some key processing considerations you need to know.

Read MoreLatest Biopolymers News And Updates

Braskem’s New Renewable Innovation Center Opens

The Lexington, Massachusetts, center will accelerate innovation in renewable chemicals and materials.

Read MoreNREL Builds and Tests Wind Turbine Blade With Recyclable Resin

Material can be sourced from biomass and chemically recycled, enabling sustainable end-of-life management.

Read MoreBASF Launches Product Carbon Footprint (PCF) App on its Products

The company’s PCF app PACIFIC is available in the Catena-X Automotive Ecosystem in the Cofinity-X app store.

Read MoreAnother PLA World-Scale Supplier Is Bound to Affect Global Availability, Pricing

SS Royal Kit Emirates and Global Biopolymers form Emirates Biotech venture to produce PLA.

Read MoreFlame-Retardant PP Compounds

Sirmax North America now offers a broad range of these compounds within three key product families

Read MoreBiomass-Balanced PBAT for Compounding of Bioplastics for Packaging

Renewable feedstock has replaced fossil feedstock in BASF’s ‘industry-first’ biomass-balanced ecoflex PBAT.

Read MoreFeatured Posts

NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreMaking a Play With PHA

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

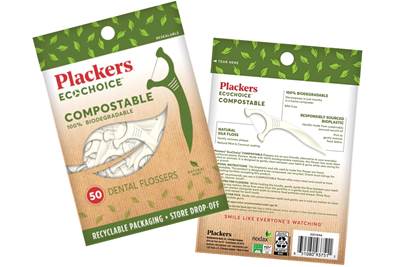

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreFAQ: Biopolymers

Global bioplastic production capacity is expected to increase to 4.8 billion lb by 2024, driven by OEMs and brand owners steadily converting applications to these “green” materials. If you’re looking to supply compounds to meet this demand, here are some key processing considerations you need to know:

1. Buy flexible extruders

2. Remember that biopolymers are typically hygroscopic

3. Consider that biopolymers are shear- and pressure-sensitive

4. Biopolymers degrade rapidly, making purging important