Commodity Resins

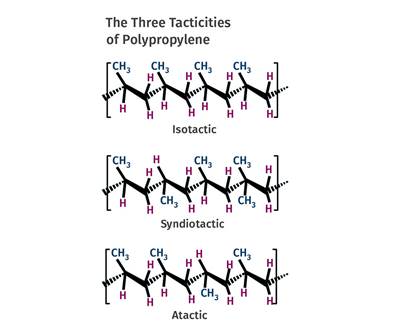

The five main commodity resins are polyethylene (LDPE, LLDPE, HDPE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET). Key applications range from flexible and rigid food and non-food packaging, to a broad range of consumer goods products, agricultural and industrial products, automotive, and construction, including pipes.

ESSENTIAL READING

VIEW ALLFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreFundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

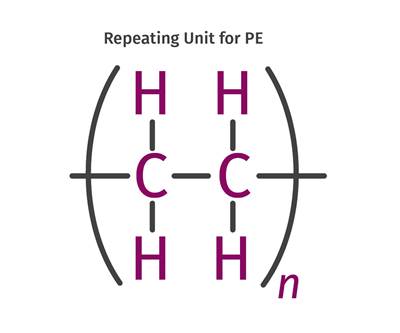

Read MoreThe Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreThe Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read MoreLatest Commodity Resins News And Updates

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreExxonMobil Collaborated on Creation of a High-Performance, Recyclable, Nonlaminated Freezer Film

The company partnered with provider of plant-based foods Bunduelle and film extruder Constantia Drukpol.

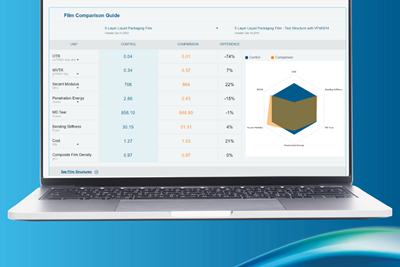

Read MoreUpdated Interactive Tool for Predicting Multilayer Film Performance

NPE 2024: NOVA Chemicals presents the latest enhancements to its Bonfire Multilayer Property Predictor and new Syndigo rPE portfolio

Read MoreLyondellBasell Invests in Advanced Technology for Masterbatch Solutions

The new investment for the Americas complements the company’s testing assets in Europe.

Read MoreBallistic-Resistant Composite Panels Made With E-Glass and Thermoplastic Resin Systems

Avient’s Polystrand ThermoBallistic thermoplastic panels are a cost-competitive alternative to other fibers and thermosets

Read MoreINEOS and Supply Chain Partners Collaborate on Premium Film Packaging with 50% Recycled Plastic

PepsiCo launches its new Sunbites brand snack packaging in the U.K. and Ireland

Read MoreFeatured Posts

Prices Drop for PP, Largely Flat for PE, PS, PVC, and PET

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

Read MorePrices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Read MoreHeartland Polymers, North America’s Newest PP, Producer Makes NPE Debut

NPE2024: The only Canadian-based PP producer operates its inland complex just east of Edmonton, Alberta.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreFAQ: Commodity Resins

Polyethylene is considered a “commodity” material, a designation that gives the impression that not much thought needs to go into picking the correct grade of material. But PE can be remarkably complicated simply because it is the only polymer that is available across a wide range of densities.