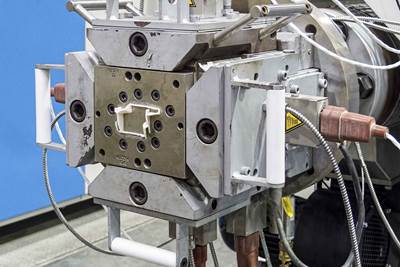

dies

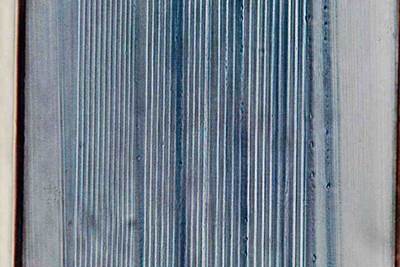

Novel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

Jim Callari

Editorial Director, Plastics Technology

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreNew Rotary Die and Cam Lock Design for Tubing

NPE2024: New design enables quick and easy assembly and disassembly of the crosshead, and eliminates the socket head cap screws.

Read MoreCrosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Read More'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

Read MoreAuto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreUpdated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read MoreSpiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

Read MoreDavis-Standard to be Systems Integrator for Novel EDI Flat Die

Die uses motorized lip-adjustment, said to be three to five times faster than heated-bolt adjustments.

Read MoreLarge Die Cart with Crosshead

Can be assembled and disassembled easily. Stand also serves as cleaning station.

Read MoreRotating Tubing Dies Increase Wall Strength

New design of rotary inline or crosshead dies feature speeds to 1000 rpm.

Read MoreIs Your Profile Die the Problem? Or Is It the Heaters?

When a profile is not being extruded to the tolerances of previous runs, the die is often suspect—but the real problem may be the heaters. Learn the five heater-band principles before you do any profile die work.

System Allows Fast, Efficient Die Cleaning

Processing Technologies International LLC (PTi) has developed a die splitting cart called uCAMS (Universal Cleaning Assembly and Maintenance System). The system was designed with the goals of flexibility, ease, and operator safety in regards to maintenance and upkeep of an extrusion die.

Read MoreNovel Line Produces 27-Microlayer Blown Film

Italian machine builder unveils blown film system that relies on feedblocks—far more common in flat-die processing—to yield thin yet strong film.

Read MoreItalian Machine Builder GAP Installs 27-Layer Blown Film Line

System consists of nine extruders feeding 400-mm annular die, an automatic gauge-controlling air ring, and other features.

Read MoreExtrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreNew Die-Cleaning System Boosts Efficiency for Film Processor

IPG’s investment in Schwing’s cleaning system impacts processor’s bottom line by getting dirty film dies back in production quickly.

Read MoreProfile Die Design Software Simulates Cooling, Shrinkage

Enables use up of to 20 calibrators in the cooling system.

Read MoreAll-Nanolayer Disk Die Pushes Blown Film Layer Limits

Patented die aims to extend blown film layer limits beyond the current nine- and 11-layer standards currently considered high-tech.

Jim Callari

Editorial Director, Plastics Technology

‘Game Changing’ Flat Die Lives Up to Its Billing

Revolutionary ‘touchless’ die and control system for cast film and coating/laminating offer speed, efficiency and operational efficiencies to processors that were previously ‘unheard of.’

Read MoreTooling: Back to Basics On Die Springs--Part 2

Follow these steps for proper die-spring selection and installation.

Read MoreTooling: Back to Basics on Die Springs Part 1

Some molding shops insist that all of their molds have springs to return the ejector plates. And there are lots from which to choose. Here we’ll focus on compression die springs for injection molds.

Read MoreNew Mold Grease Smooths Operations for Troublesome Tool

Switching to a new synthetic grease helped an injection molder keep a difficult die running, eliminating unplanned downtime and cutting scrap.

Read MoreExtrusion: Auto Die for Coating Applications

Equipped with a motorized internal and external deckling system for safe and easy operation.

Read MoreExtrusion: Enhanced Deckle Boosts Coating Productivity

Simplified mechanisms for Nordson EPC die streamline the adjustment of coating width while reducing the size of edge bead.

Read More