Injection Know How

Latest Injection Know How Articles

VIEW ALLImportant Factors and Approaches to Estimating Residence Time in Injection Molding

Residence time can have a dramatic impact on part quality and production efficiency but determining its value can be tricky. Use these methods and formulas to accurately measure residence time and enable it to inform everything from scheduling jobs to optimizing a process.

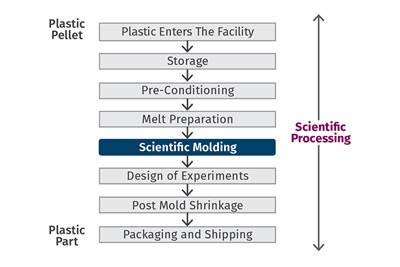

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreGet the Most From Fiber-Reinforced Thermoplastic Composites Parts

There are five specific areas that designers and manufacturers need to consider to realize the potential of these unique materials.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreStarting or Restarting an Injection Molding Machine — What Works Best?

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

Read MoreHome In on These Six Variables to Monitor Molding

There are hundreds of variables in molding, but focusing on these six will help you make consistent parts.

Read MoreLatest Injection Know How News And Updates

Featured Posts

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreRevisiting the '5 M's' of Molding

All injection molding ultimately comes down to the “Man, Mold, Machine, Material and Method.” But those key aspects can be viewed differently if you’re auditing mold changes before startup or troubleshooting changes for an already validated process.

Read MoreAttending NPE2024 From the Perspective of a Molder

NPE2024 has come and gone, but before it’s completely in our collective rearview, Plastics Technology asked Rodney Davenport, vice president at injection molder CH3 Solutions, for a processor’s perspective on the big show.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreDiagnosing Defects: Determine True Root Cause Before Adjusting a Process

Common defects can have common causes — flash equals worn mold shutoffs, right? Except when they don’t. Trust your eyes, but verify the root cause before adjusting a process.

Read More