Know-How

Narrow Your Know-How Search

Latest Know-How Articles

VIEW ALLHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

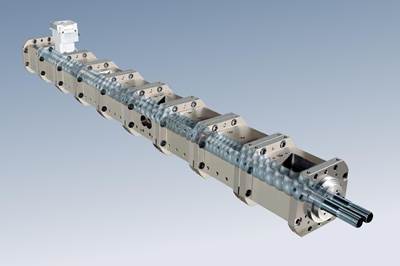

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreWhat's Restricting My Output Rate?

In a single-screw extruder, it could be an improperly designed barrier flighted entry section. Here’s why.

Read MoreImportant Factors and Approaches to Estimating Residence Time in Injection Molding

Residence time can have a dramatic impact on part quality and production efficiency but determining its value can be tricky. Use these methods and formulas to accurately measure residence time and enable it to inform everything from scheduling jobs to optimizing a process.

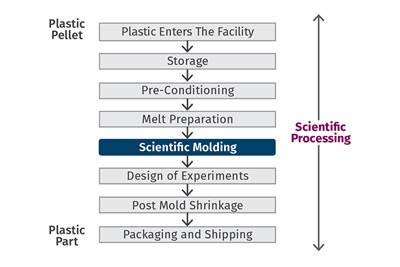

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreLatest Know-How News And Updates

Solving Issues with Gloss

Your problem may be related to tooling, material, processing, or combinations thereof. Here’s how to find the root cause.

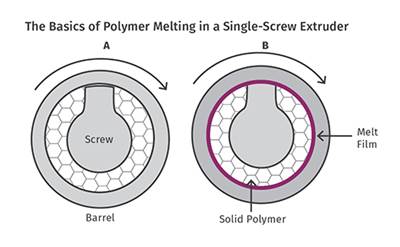

Read MoreEXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

Read MoreFeatured Posts

How to Decrease the Extrudate Temperature in Single-Screw Extruders

In many cases, decreasing the discharge temperature will improve product quality and perhaps even boost rate. Here are ways to do it.

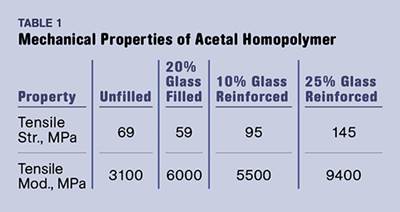

Read MoreGet the Most From Fiber-Reinforced Thermoplastic Composites Parts

There are five specific areas that designers and manufacturers need to consider to realize the potential of these unique materials.

Read MorePolymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreIn Single Screw Extruders, Mixing Starts in the Melting Process

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

Read More