Plastics Materials

Materials used in plastics processing include plastics, thermoplastics or polymers, materials are the stuff of which molded and extruded parts are made. Broad subcategories include commodity materials such as polyethylene, polypropylene and PVC; and engineering materials such as nylon, acetal and ABS for applications requiring higher performance.

Narrow Your Materials Search

ESSENTIAL READING

VIEW ALLHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreThe Effects of Time on Polymers

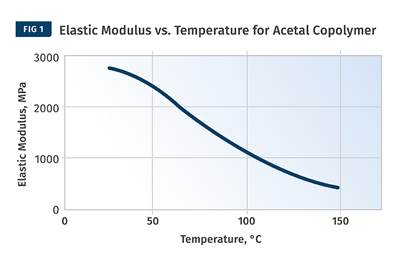

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreThe Effects of Stress on Polymers

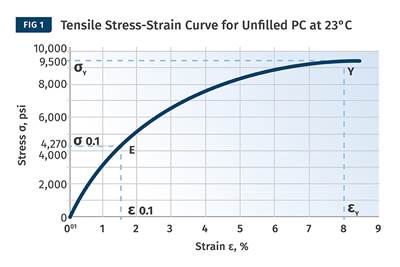

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreTracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

Read MoreTracing the History of Polymeric Materials, Part 25: Silicones

The long road to the development of silicone resulted in a chemistry that is remarkably versatile.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreLatest Materials News And Updates

Dow Revoloop Resins for Cable Jacketing With Postconsumer Content

Announced resins will incorporate recycled material.

Read MoreExxonMobil Launches New Materials Portfolio Brand

The Signature Polymers brand, which includes all polyolefins, is focused on delivering best-in-class service and partnership.

Read MoreBiomass Balanced LCP for Reduced CO2 Emissions and Improved Renewable Content

Polyplastics’ Laperos bG LCP is slated for commercialization in spring 2025.

Read MoreSPE Foundation Establishes Memorial Scholarship for Materials Guru Sepe

Mike “The Materials Analyst” Sepe was a long-time SPE member and contributed more than 100 columns to Plastics Technology.

Read MoreCompatibilizer for Nylon/ABS Alloys

CAI Performance Additives’ ST-AN3230 has shown to improve both compatibility and performance of nylon/ABS alloys.

Read MoreEco-Friendly Flame-Retardant Synergist

CAI Performance Additives’ ST-FR322 effectively replaces antimony trioxide in several thermoplastics.

Read MoreFeatured Posts

Prices Up for PE, ABS, PC, Nylons 6 and 66; Down for PP, PET and Flat for PS and PVC

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

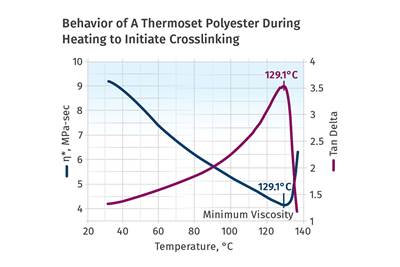

Read MorePart 3: The World of Molding Thermosets

Thermosets were the prevalent material in the early history of plastics, but were soon overtaken by thermoplastics in injection molding applications.

Read MorePrices Drop for PP, Largely Flat for PE, PS, PVC, and PET

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

Read MoreLet's Take a Journey Into the World of Thermosets: Part 2

Most thermoset molding processes still treat the mold like a black box where the curing process is invisible and mysterious, and nobody knows what is happening to the material until the mold opens. That just isn’t so.

Read MorePrices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Read MoreHeartland Polymers, North America’s Newest PP, Producer Makes NPE Debut

NPE2024: The only Canadian-based PP producer operates its inland complex just east of Edmonton, Alberta.

Read MoreMaterials Supplier Categories

- Additive Manufacturing (3D Printing/Prototyping Materials)

- Cellulose Acetate Propionate

- Starch-based Polymers

- Nylon--Type 6

- Polycarbonate/ABS Alloys

- PVC--Dispersion and Blending Resins

- PPE/Nylon Alloys

- Cellulose Acetate Butyrate

- Polyester (Thermoplastic)--PETG Type

- Polyethersulfone

- Adhesion-Modified HDPE

- Recycled/Reprocessed Materials--Ground Flake Form

- Polyphthalamide (PPA)

- PVDC--Coating Grades

- Polyphosphonate

- Other Styrene Copolymers

- Acrylic/PVC Alloy

- Polycarbonate/Polyester Alloy

- PVC--Flexible Compounds

- Polyester (Thermoplastic)--PCT Type

- Thermoplastic Elastomers--Polyamide Type

- Polyamide, Aromatic

- Nylon--Type 69

- Ionomers

- Liquid Crystal Polymers

- Ethylene Plastomers

- Nylon/Polypropylene Alloys

- Nylon--Type Mxd6

- Ethylene Vinyl Alcohol (EVOH)

- Polyester (Thermoplastic)--PBT Type

- Polyarylether

- Styrene Maleic Anhydride (SMA)

- Prepregs (thermoplastic)

- LLDPE

- ASA Copolymers and Alloys

- Nylon/Abs Alloys

- Polyarylate

- Polybenzimidazole (PBI)

- Polysulfone

- Cyclo-olefin Polymers

- PVC--Rigid Compounds

- Thermoplastic Elastomers--Olefinic Type

- Polyester (Thermoplastic)--PTT Type

- Nylon--Type 610

- PVC--Chlorinated PVC (CPVC)

- Reinforcements--Ceramic Fibers

- Thermoplastic Elastomers--Urethane Type

- Reinforcements--Continuous Fiber Rovings, Tows, Yarns

- Core Materials

- PHA, PHBV Biopolymers

- Reinforcements--Carbon or Graphite Fiber

- Polyphenylene Sulfide (PPS)

- Nylon--Type 612

- Reinforcements--Mineral Fiber

- Adhesion-Modified LDPE

- PPE/PP Alloys

- Polyester (Thermoplastic)--Other Types

- Stock Shapes--Rod, Tube

- Ethylene Vinyl Acetate (EVA)

- Acrylics

- Recycled/Reprocessed Materials--Bale or Bulk Form

- Polystyrene

- SAN

- Cellulose, Ethyl

- Reinforcements--Fabric, Mat, Veil, Felt

- Stock Shapes--Film

- Polymethylpentene

- UHMW PE

- Polycarbonate

- Polyester (Thermoplastic)--PCTG Type

- Polyestercarbonate

- Nylon--Type 6/66 Copolymer

- Acrylic Copolymers

- Polyetherimide

- Syndiotactic Polystyrene (SPS)

- Polyarylsulfone

- PVC--Plastisols, Organosols

- Nylon--Type 11

- Reinforcements--Aramid Fiber

- Polybutylene

- Polyetheretheketone (PEEK), Polyetherketone (PEK) and Other Polyketones

- PPE/PS Alloys

- LDPE

- PVC--Suspension or Mass General-purpose Resins

- Nylon--Amorphous

- Nylon--Type 46

- Thermoplastic Elastomers--Vinyl Type

- Polyphenylsulfone

- Reinforcements--Nylon, PET or PP Fiber

- Acetal

- AES Terpolymer

- PVC--Copolymer Resins

- Acrylonitrile Copolymers

- Polyester (Thermoplastic)--PET Type

- Adhesion-Modified LLDPE

- Polyamide-imide

- Ethylene Copolymers and Alloys - Other

- ULDPE/VLDPE

- HDPE

- EPS Bead (including Copolymers)

- Expandable Polyolefin Bead

- Acrylic/Polycarbonate Alloy

- Polyimide (Thermoplastic)

- Polyester (Thermoplastic)--PCTA Type

- Fluoropolymers

- PVDC--Extrusion & Molding Grades

- ABS/pvc Alloy

- Thermoplastic Elastomers--Styrenic Type

- Nylon--Type 12

- Thermoplastic Urethane (Non-Elastomeric)

- Nylon--Type 66

- Thermoplastic Elastomers--Polyester Type

- Polypropylene (including Copolymers)

- Polylactide (PLA) Polymers

- Recycled/Reprocessed Materials--Pelletized Form

- ABS

- Stock Shapes--Sheet

- MDPE

- Biodegradable, Photodegradable Resins and Compounds

- Reinforcements--UHMW-PE Fiber

- Reinforcements--Glass Fiber

- Phenoxy

- Cellulose Acetate

- Butadiene Styrene Copolymers (not Including Elastomers)

- Nylons - Other

- Reinforcements--Natural Fibers

- Reinforcements--Discontinuous Fibers (Chopped, Milled, Staple)

- Thermoplastic Elastomers--Polyether Block Amide (PEBA) Type