monitoring

Real-Time Production Monitoring as Automation

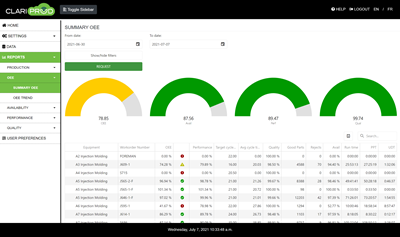

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Tony Deligio

Editor-in-Chief, Plastics Technology

Radar Level Sensor Streamlines Bulk Material Inventory Management

NPE2024: The NCR-86 is designed to ensure rapid data updates, enhancing efficiency in inventory management.

Read MoreEigen Integrates Ampacet Color Monitoring into Machine Vision Solutions for Plastics

Injection molders, blow molders and extruders looking to avoid downtime and reduce scrap related to defect detection and color monitoring get a single solution for inline quality monitoring and management.

Read MoreIndustry 4.0 Without Fear: Modular MES Software Lets You ‘Start Simple’ and Add on Later

‘Don’t be afraid of MES.’ App-based platform can start with monitoring just downtime and cycle time on a few machines and add machines and functionality later.

Read MoreSoftware Tracks Energy Waste in Real Time

Affordable add-on to production monitoring software alerts uses when energy is being wasted.

Read MoreHow Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

Read MoreHow Production Monitoring Can Make You a Better Processor

Real-time information on all your production equipment not only boosts productivity and profitability, but it encourages proactive vs. reactive thinking and sharing of best practices. See how this approach benefited a blow molder with 19 plants.

Read MoreFive Strategies for Cutting Reshoring/ Nearshoring Costs via Data Automation

Leveraging real-time data via tools like ERP and MES is one form of automation plastics processors can apply to capitalize on reshoring and nearshoring trends.

Color-Measurement for Extrusion, Molding

System helps processors control the cost of quality due to color variations, using real-time color data for QC analytics and color optimization.

Read MoreAI Machine Monitoring Arrives from Google Cloud

A new “end-to-end packaged solution” connects shop-floor machine monitoring to the cloud, with AI analytics to turn data into actionable knowledge.

Read MoreNot Thrilled by All the ‘4.0’ Talk?

Are you (perhaps secretly) put off by expressions like Industry 4.0, Internet of Things, Big Data, Smart Factories, Digitalization and so forth? If so, you’re not alone. You might be friendlier to terms like operational Transparency and Visibility.

Read MoreCloud-Based Real-Time Injection Mold Monitoring System

Mold-Masters SmartMOLD combines inmold sensors with cloud-based software to provide real-time process data, maintenance tracking, document storage, reporting, alerts and more.

Read MoreMachine Monitoring System Now Offers ‘Escalating Alerts’ of Downtime & Alarms

Guidewheel’s FactoryOps machine monitoring platform has a new feature to ensure faster response to downtime or other alerts.

Read MoreFakuma: Tiny Sensors Target Hot Runners, Additive Manufacturing

Kistler says the 3-mm diameter 4004A pressure sensor for hot runner and additive manufacturing applications will be available for three measuring ranges in 2022.

Read MoreManufacturers’ Superpower: ‘X-Ray Vision’ into Your Processes

Meet a ‘new’ name (to North American processors) in MES software, which provides a simple, modular way to achieve visibility into your production operations.

Matthew Naitove

Contributing Editor, Plastics Technology

Real-Time Production Monitoring Service Made Standard

Husky Injection Molding Systems is making its Advantage+Elite proactive, predictive, transparent process monitoring platform a standard feature on all PET and closure systems.

Read MoreMachine Monitoring Becomes Simpler And More Affordable Than Ever

A new application of an established technology makes production monitoring accessible to any manufacturer, with any type of equipment, and in almost no setup time.

Read MoreEquitech Establishes Worldwide Extruder OEM Sales Program

Manufacturers of extruders, feeders, and other processing equipment can work with Equitech to integrated its technology into their control and process management systems.

Read MoreEquitech Buys Stake in CompSol USA

Acquisition specializes in manufacturing of opto-electronic devices.

Read MoreContinuous Machine, Process Monitoring

Provides critical and timely information for processors to improve overall line performance and plan scheduled maintenance activities.

Read MoreUse Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Upgraded Controller for Auxiliaries

Can be designed as a stand-alone or networked controller.

Read MoreSensors Bring Batteryless Machine Monitoring to all Corners of a Plant

Powered by a machine’s heat or ambient light, a new batteryless vibration sensor monitors machine conditions continuously, including in hard-to-reach places.

Read MoreIn-Line Radar-Based Measurement of Extruded C900 PVC Pipe Reduces Material Cost, Improves Quality

New radar-based measurement technology enables processors to extrude higher-quality pipe with less material. With an automated closed-loop control system you’ll get more output and less scrap to significantly lower costs.

Read MorePackaging Molder Adopts Wireless Machine Monitoring

A molder of injection and blow molded packaging is outfitting more than 70 machines with a simple, highly adaptable system to monitor machine status and production.

Read MoreSystem Moves Color Control From Lab to Production Floor

In-line spectrophotometer from Equitech promises to move color management out of the lab and right to the extrusion line to slash waste and improve quality.

Read MoreIs Your Cleanroom Operating Correctly?

Monitor your cleanroom remotely on your phone and get alarm notices if sensors detect a problem.

Read More