screws

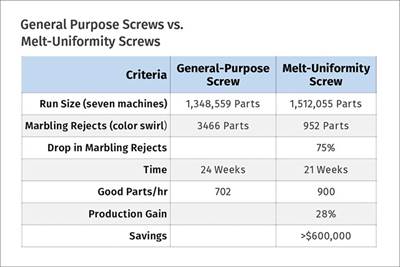

Improve Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

John Bozzelli

Founder, injection Molding Solutions

Extreme Coatings Names Jackson Director, North American Sales

Company also extends its global manufacturing footprint.

Read MoreXaloy Invests in New R&D Center

Xaloy is investing in a new R&D Facility for plasticizing equipment in northeast Ohio with aid from JobsOhio R&D Center Grant.

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreXaloy to Reopen Virginia Manufacturing Facility

The Pulaski site was closed in 2016 by former owner Nordson, which consolidated screw and barrel operations in Ohio

Read MoreNew Technology Opens a Predictive Window Onto Screw Wear

Despite their integral role in transforming pellets fed through the hopper into parts ejected from the mold, visibility into the performance, health and efficiency of screws is difficult to discern for many reasons, not the least of which being the fact they’re located inside a barrel.

Read MoreNordson Selling Screw, Barrel Business

Private equity firm Altair expects to close on acquisition during the first quarter of next year.

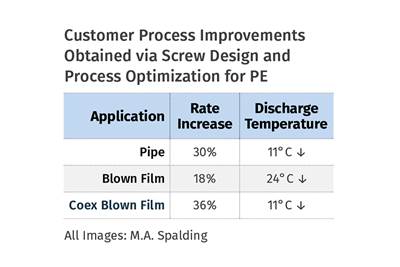

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Follow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

Read MoreScrew-Recovery Problems Call for Special Screw Design

In injection molding, the penalty for using a general-purpose screw in an application that has special requirements often takes the form of longer cycle times. Barrier designs can help.

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

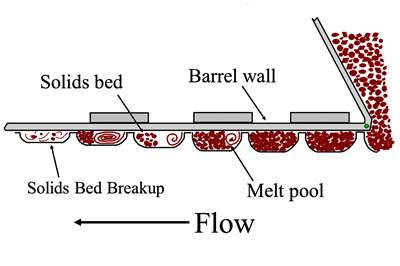

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreMilacron Renews Partnership With Barr for Screw Technology

Milacron has extended its exclusive partnership to offer Robert Barr Inc. designed screws on new Milacron injection molding machines or as aftermarket add-on to existing presses.

Read MoreNordson to Open Xaloy Tech Center in Ohio

Sixth new Nordson lab will open in Austintown, Ohio, at a newly built plant for Xaloy screws and barrels.

Read MoreImprove Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

John Bozzelli

Founder, injection Molding Solutions

Extrusion: Two-Stage Screw Offers Distributive, Dissipative Mixing

New design from Davis-Standard offers outputs comparable to barrier screws at lower melt temperatures.

Read MoreBarrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

Read MoreWhy Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

Read MoreSimple Scale-Up Calculations for Melting

You can avoid complicated melting equations when designing or evaluating a screw by using simpler methods that can save time and provide good results.

Read MorePartner Sought for Commercialization of "Revolutionary" Extruder for Recycling

The cylindrical extruder developed by VTT could revolutionize processing of recyclable materials including plastics, textiles and food waste.

Read MoreExtrusion: Compact Extruder Is Potent, Energy Efficient

Small-footprint machine reportedly uses up to 95% less energy/lb of material processed and can typically achieve dimensionally stable product within 20 min. of being turned on.

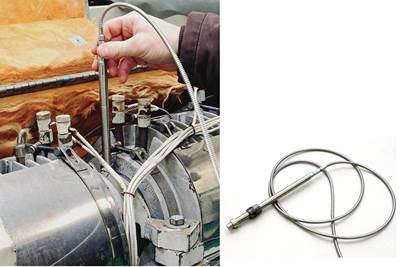

Read MoreTake the Guesswork Out of Determining Screw, Barrel Wear

New technology from Glycon takes real-time measurements of screw and barrel wear and provides data to guide processors as to when the time may be right to swap out these components.

Jim Callari

Editorial Director, Plastics Technology

Unraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read MoreExtrusion: A Simple Way to Evaluate Extruder Screws

While there’s lots of data that influences screw design, processors usually don’t have access to it. So instead, try calculating drag flow to see if your screw is working properly.

Read MoreExtrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

Read MoreExtrusion: Understanding Weld Failures

Hard-surfacing failures without evidence of burrs indicate possible weld bond issues.

Read More