Single-Screw Compounding

Latest Single-Screw Compounding Articles

VIEW ALLAdd Value to Your Compounding Operation

Inside: Insights on three emerging, higher-margin growth areas for compounders.

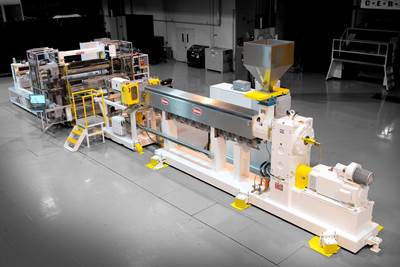

Read MoreCompounding: Higher-Performing Pilot Machine

Series is height adjustable and can process highly filled and viscous materials.

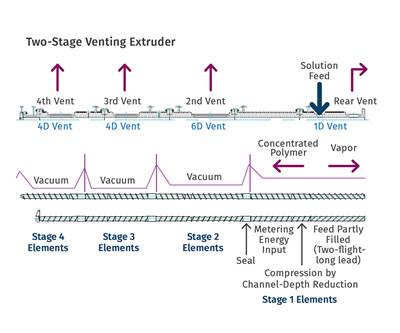

Read MoreCompounding: Part 2 of 2 Demystifying Devolatilization

Here are some simple tools to help monitor and optimize your devolatilization process.

Read MoreCompounding: Part 1 of 2: Demystifying Devolatilization

Very little has been written about this critical topic, and most of what has been published is theoretical. Here’s some practical guidance to help you better understand the process and improve your operation.

Read MoreNordson Opens Pelletizing, Melt-Delivery Lab in N.C.

Lab has pelletizing line that can operate at rates to 1000 lb/hr.

Read MoreStrand Pelletizing: Follow These Steps to Determine Your Water Bath Length

Use heat-transfer equations as a shortcut to get you in the ballpark of how long your pelletizing water bath should be.

Read MoreLatest Single-Screw Compounding News And Updates

Compounding: Strand Pelletizers Improve Quality, Ease Handling

Dual-bearing strand pelletizers re-engineered based on field experience and current market demands.

Read MoreMaag Americas Names Baumann V.P., G.M.

Machinery vet to head up sales of filters, pumps, pelletizers and pulverizers.

Read MoreInjection Molding: Injection Machine Configured for In-Line Compounding

In-line compounding option for Wilminton Machinery’s MP800 800-ton, medium-pressure injection press can handle up to six components.

Read MoreFeatured Posts

K 2019 Preview: Green's the Theme in Extrusion & Compounding

Themes of sustainability and the Circular Economy will be visible at the booths of many suppliers of extrusion and compounding equipment—film, in particular.

Read MoreExtruder Degassing: Is a Central System Right for You?

Centralization vacuum pumps have been used for many decades, most widely used in packaging. For extruder degassing the technology can be useful when several production lines are operated in parallel

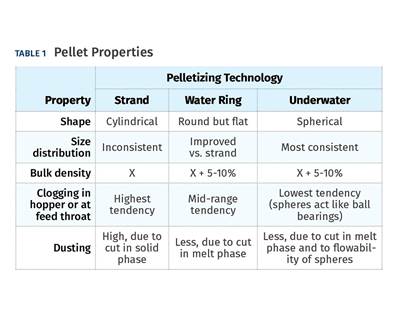

Read MoreFollow These Guidelines to Select the Right Pelletizing System

Which pelletizing system is right for your application? Is the one you’re using today necessarily the right choice for tomorrow? Here’s is an analysis that can help you decide among the three major options.

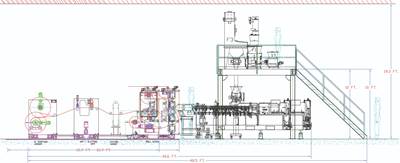

Read More‘Follow the Plan’ When Installing and Commissioning Compounding Lines

A fully operational and documented system doesn’t happen by chance. An efficient, well-designed installation plan, prepared well in advance, will put you on the path to maintaining a timeline and budget.

Read MoreK 2016 Extrusion: Speed, Versatility Rule the Day at K

Shorter product runs mean frequent product changeovers for processors, and suppliers responded to these trends across all extrusion technologies.

Read MoreNew Culture, New Capabilities, New Challenges

Over the last few years, Henkel has not only transformed what its Richmond facility does, but also altered how it operates in terms of culture.

Read More