Molder Takes 3D Printing In-House to Speed Product Development

Matrix Tooling/Matrix Plastic Products

“Bringing this function in-house is very much in keeping with the way our company conducts its business.

“Bringing this function in-house is very much in keeping with the way our company conducts its business. We design and build our own molds in-house. We try to do most everything in-house,” says senior design engineer Tom Ziegenhorn of Matrix Tooling, Inc., and Matrix Plastic Products, a full-service plastic injection molding and tooling specialist in Wood Dale, Ill. Ziegenhorn is referring to the company’s recent acquisition of the Objet30 Desktop 3D Printer from Objet of Israel, which is in the process of merging with Stratasys, Inc.

A growing number of injection molders are making use of this and other rapid-prototyping technologies, and as their utilization increases, more and more of them contemplate buying their own system. Prior to purchasing the Objet30 this past May, Matrix had used outside prototyping services. “We felt that once we brought this capability under our roof, we would be much more likely to expand its uses. Now we can produce 3D models within hours instead of the typical three- to five-day wait time for an outside service,” says Ziegenhorn.

Matrix does a lot of product development work with customers, and the new system’s 3D models help communicate concepts much quicker. “Having 3D parts in hand is really beneficial for both our customer and us, especially for those parties who are not directly involved with CAD, because everyone gets a much clearer view of the project. It is particularly helpful when very small, complex parts, overmolded components, assemblies, or secondary operations are involved. We can experiment with ideas of how to make things better, faster and more economically,” says Ziegenhorn.

With 50 employees and 30,000 ft2, Matrix builds molds for OEMs and is also a custom injection molder specializing in small, intricate parts. Medical device components account for more than half of its business, followed by electronics, military, and other applications. Matrix works with a wide range of engineering resins, including PEEK and LCPs. Many of the parts are very complex and smaller than 1mm2. Matrix uses the Objet30 during product development, primarily for determining fit and form. “We do not use these parts to test performance or function of the finished product, due to the limitations of the printing materials,” says Ziegenhorn. But the company is finding other uses for the 3D printer, such as to produce fixtures, instead of conventionally machining them. These fixtures are used for inspection and secondary operations on molded parts.

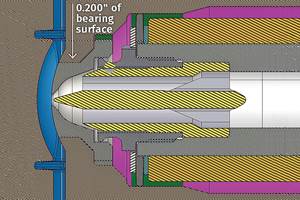

Resolution of the printer has its limits. Ziegenhorn says, “It can only go so small. For details under 0.010 in., the definition is not quite so crisp. We did look at higher-end machines, and then weighed the capabilities and cost of the various systems relative to our needs. This Objet30 gave us the best bang for our buck.”

This desktop 3D printer, when first launched in 2010, was the only “office-friendly” system of its kind, capable of printing finely detailed models in a choice of five different materials and five colors. It can create parts within an envelope of 300 x 200 x 150 mm, directly from a CAD file, building them up from thin (0.0011 in.) layers of a UV-curable photopolymer deposited with inkjet-type technology.

Related Content

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More