Getting the Most Out of Injection Molding Simulation

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

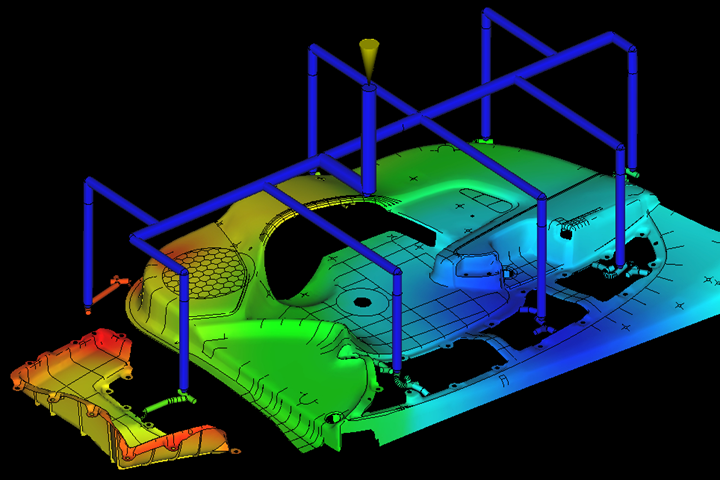

Simulation has long been a powerful tool allowing molders to pinpoint potential design and process pitfalls on a computer screen — before mold steel has been cut — instead of discovering them on the production floor, when the time and cost to fix the issue(s) quickly becomes prohibitive. As the technology advances, it provides molders even greater capabilities, giving them new tools to apply.

At Molding 2023 (Hyatt Regency Minneapolis; August 29-30), multiple speakers will address different ways simulation can positively impact injection molding operations.

- Moldflow Material Substitution Process: How to Find Equivalent Grades — David Corsi, Beaumont Technologies

- Dramatically Improve Molding Profitability with Injection Molding Simulation — Todd Bryant, Paulson

- How Front-End Simulation Alleviates the Challenges of Plastic Injection Mold Design. — Christopher Blake, Maya HTT

Learn more about Molding 2023, which will be collocating with MoldMaking Technology magazine’s MoldMaking Conference (registrants to either event can attend both), including speakers addressing sustainability and automation.

Attendees to Moldmaking 2023 (August 29-30; Minneapolis, Minn.) will see multiple presentations touching on the role of simulation in injection molding today.

Photo Credit: Autodesk Moldflow

Related Content

-

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

Are Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

.png;maxWidth=300;quality=90)