Plastics Purging Compounds

Purging compounds clean out plastics processing machinery between production runs. Types include chemical purging; abrasive purging; and non-abrasive purging.

ESSENTIAL READING

VIEW ALLHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

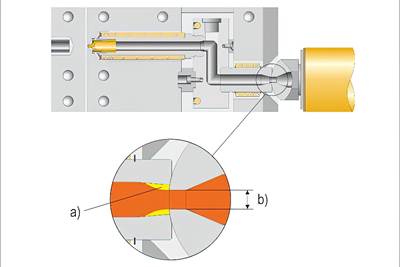

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreA Planned Purging Program Can Boost Your Hot-Runner Efficiency

Molders can increase the efficiency of their hot-runner operations if a strategic approach is developed to address the need for required resin and color changes.

Read MoreThe Experts Speak: Seven Cost-Saving Purging Tips for Compounding Twins

Purging gurus from the material, machinery and compounding sides of the industry offer their insights on best practices and tips that can keep your compounding twin-screw extruder up and running.

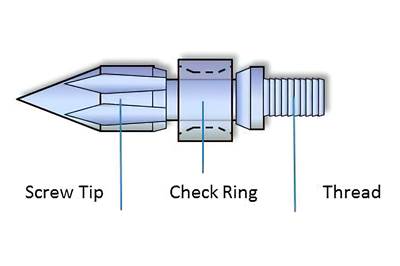

Read MoreFollow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

Read MoreLatest Purging Compounds News And Updates

Asahi Kasei Plastics North America Welcomes New President and COO

With APNA’s president and COO Todd Glogovsky’s retirement April 1, his successor will be v.p. of commercial sales Phani Nagaraj

Read MoreCast Acrylic Purging Compound

Mechanical purging compound comes in granulate form, enhancing handling, storage and grittiness for cleaning.

Read MorePromotions at Asahi Kasei Plastics North America

Tom Hanvey and Yoko Tanaka move onto new positions.

Read MoreAsahi Kasei Plastics North America Merges with Asahi Kasei Asaclean Americas

Merged entity to further boost best-in-class manufacturing services.

Read MoreAsaclean Launches Interactive, Educational Website

Offering nearly 500 pages of purging content in English & Spanish, the new site is suited to both new and experienced processors.

Read MoreController-Guided Procedure for Faster Hot-Runner Color Changes

Husky partnered with Chem-Trend to speed hot-runner color changes, pairing a new guided procedure within the Altanium Mold Controller with Chem-Trend’s Ultra Purge brand of purging compound.

Read MoreFeatured Posts

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreRun Lots of Colors? Time to Consider a Commercial Purging Compound

Processors who use commercial purging compounds will see a reduction in scrap levels, machine downtime and overall cost.

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreFollow These Tips to Maximize Purging Efficiency

Commercial purging compounds offer dedicated solutions to your equipment cleaning needs, but some can be more effective in cleaning the ‘dead areas’ in certain screws and tooling. Follow these tips to choose the right one for your application, and make sure to follow the right protocol when shutting down for long periods.

Read MoreHeat-Activated Purging Concentrate Cuts Molder's Scrap & Changeover Times

CH3 Solutions increased productivity on its multi-cavity hot runners with new Asaclean Plus Grade concentrate.

Read MoreA Planned Purging Program Can Boost Your Hot-Runner Efficiency

Molders can increase the efficiency of their hot-runner operations if a strategic approach is developed to address the need for required resin and color changes.

Read MoreFAQ: Purging Compounds

Chemically active CPCs can be an excellent choice for fast color changes but may not be aggressive enough to thoroughly purge highly contaminated injection systems or highly filled resins. In such cases a purge formulation with a higher viscosity may be required to successfully dislodge a highly filled resin. Additionally, purging a hot-runner system requires consideration of the size of the manifold, gates, and melt channels. There is no “one-size-fits-all” purging compound; a CPC supplier is your best resource to help identify the correct purging formulation and procedure for your needs.

.png;maxWidth=300;quality=90)