New Software Manages Toolmaking Tasks

With today's mold buyers demanding speedy delivery, lower costs, and endless engineering changes, tool making can be more frustratingly complex than ever.

With today's mold buyers demanding speedy delivery, lower costs, and endless engineering changes, tool making can be more frustratingly complex than ever. DTR Software International, Jacksonville, Fla., is trying to make the task a bit easier with new enterprise resource planning (ERP) software tailored to mold making and repair. "The Toolmaker," manages just about every aspect of a tooling project--from quoting to sample production to final billing.

"We kept the software as simple as possible because there are toolmakers who don't want to spend too much time in front of the computer," says DTR co-founder Dan Dudley. "But the system offers lots of detail for those who need it."

Available this month, The Toolmaker targets the many molders with in-house tool making and repair operations. Tooling data generated by the software feeds into the suite of planning and business applications found in The Manufacturing Manager (TMM), DTR's full-fledged ERP software for injection molders and other plastics processors. DTR will also offer The Toolmaker in a stand-alone version that includes nearly all of TMM's functionality.

Categorizing your costs

At the heart of the software, which runs on Windows NT or Unix, is a new costing and quoting package tailored to tool projects, whether they represent a simple change order, a new mold, or a suite of molds.

To use the software, users first set up a grid-like template of cost categories--labor, overhead, station (or machine-hour) rates, materials, and outside contract work. Users also break their tooling project into specific job divisions, such as mold-base machining, cavity production, benchwork, and mold sampling.

According to Dudley, users control the categories and job divisions they use, and they can include a category multiple times or not at all. "The software has many functions and features that don't have to be turned on for it to run," he notes. For example, some users would not need to establish a category for outside contract work. Or cost categories for a repair project could differ from those for a brand-new mold.

Once the costing data has been set up, the costing module plays a role throughout the tooling project. For quoting purposes, it lets users make both rough and detailed cost estimates for each cost and job category. The detailed estimates within the materials category are ultimately transformed into purchase orders, inventory updates, and bills of materials, all of which the software can generate automatically, thanks to its link with TMM.

As the project gets off the ground and the steel chips start flying, the software will track actual costs. Again through the link with TMM's accounting modules, these costs accumulate in the general ledger and feed the accounts-payable and accounts-receivable modules.

Planning and scheduling

As an option, The Toolmaker can also drive DTR's advanced planner/scheduler, called "Expert Planning System (XPS). In this case, the job divisions from the costing module become the basis for both actual shop-floor schedules and "what-if" scheduling scenarios. From each job division, the software can automatically generate a work order. The scheduler, which presents data in tabular and graphical formats, even provides for scheduling activities like outside contract work and mold sampling.

Since XPS is a finite-capacity scheduler, it allows users the option of constraining their schedules according to availability of individual machines, workers, or any other resource. Or, they can schedule larger classes of machines and labor specialties. "The schedule can be as rough or as detailed as they want," Dudley says.

XPS also optimizes schedules according to user-specified criteria, such as "early finish" or "fast production rate."

Handles business functions

Whether sold as a stand-alone or a module, The Toolmaker addresses the full range of business tasks. Besides planning and scheduling, these include shift reports, time-card generation, and payroll.

The Toolmaker costs $5000 as an add on to TMM, which costs $22,500 plus $2500 per active user. Pricing for the stand-alone package will be $22,500 plus $2500 per active user. XPS costs $7500 per seat.

Related Content

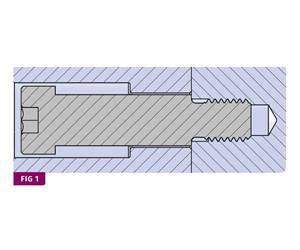

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePrecision Processing Requires Precision Equipment

Moretto offers plastics processors and micromolders for a broad suite of auxiliary solutions targeted specifically for precision processing.

Read More