Plastic Pallets Gain Ground In an Eco-Conscious World

Low-cost wood is still king, but plastics’ reusability is a growing attraction among manufacturers looking for sustainable material-handling options. The one major hurdle is today’s high resin prices.

The iconic wood pallet remains an omnipresent force in transportation, distribution, and storage of manufactured products throughout the world. Its pre-eminence has been dictated largely by cost, but plastic pallets continue to make inroads because of their durability, reusability, and light weight. Plastic pallets made by injection molding, structural foam, thermoforming, rotational molding, and compression molding are gaining acceptance in a range of markets including foods, beverages, pharmaceuticals, groceries, automotive, and the U.S. Postal Service.

The difficulty and cost of wood pallet disposal has always been a concern, but today’s focus on the environment is fueling a renewed interest in the plastics alternative. Reusability is a major attraction. Several plastic pallet makers have capitalized by coming out with low-cost versions that compete favorably with wood. One method of holding down costs is to use recycled resin and scrap regrind. Also favoring plastics are international regulations that require treatment of wood to reduce pest migration in export pallets. Meanwhile, the industry’s first plastic pallet “pool” system has been launched. These RFID-enabled pallets play to plastics’ reusability, making them more economically feasible on a cost-per-trip basis.

“The sustainability issue is front and center and has given plastics an advantage,” asserts Bill Mashy, general manager of the materials handling group for injection molder Rehrig Pacific Co., Los Angeles. “But at the end of the day, it ultimately has to be the economics; I haven’t seen where industry will sacrifice economics for sustainability.”

Many observers envision plastic pallets playing an even larger role as companies adopt greater levels of automation in their warehouses. Greater automation requires repeatability and reliability, and plastics’ tailored designs and consistent dimensions and weights offer a distinct advantage over wood pallets, which are vulnerable to splintering off shards and pulling apart as nails loosen.

STEADY GROWTH TREND

Today, wood has more than 90% of the U.S. pallet market, while plastics account for 2% to 5%, according to industry estimates. Experts say there are about 2 billion pallets in use every day and approximately 700 million are made and repaired each year. Wood pallets dominate, but the plastic pallet market has doubled over the last 10 years, according to an expert at the Pallet & Container Research Lab at Virginia Polytechnic Institute and State University, Blacksburg, Va. (However, this expert—who did not wish to be identified—does not agree that there is any “technically rigorous data to support the premise that the use and manufacture of a plastic pallet results in less of an environmental impact than a wood pallet.”)

A recent study by the Freedonia Group in Cleveland says plastic pallets will enjoy the highest growth rate, advancing 2.4% annually to over 130 million pallets by 2012, though their market share will still be under 10%. Besides durability, reusability, and light weight, manufacturers and shippers are increasingly drawn to plastics’ stacking and nesting ability, easy repairability, and color and branding options. Meanwhile, demand for wood pallets is projected to increase at a rate just below that of the market average, partly due to growth of pallet refurbishing services. Overall, U.S. pallet demand is forecast to grow 1%/yr through 2012 to 1.5 billion pallets valued at $16.8 billion.

Plastic pallets date back to the 1960s and were first used in sanitary applications for raw foods. Since then, significant improvements in materials, design, and processing have lowered their cost and made them more competitive. In the 1980s, the automotive market pioneered the use of reusable plastic pallets to minimize handling costs and eliminate disposable packaging issues.

Because they cost more than wood, plastic pallets have always had their niche in managed pools or captive closed-loop systems for work-in-process or distribution. “With a closed-loop system, the dollars and cents are clear,” says Dave Wyckoff, director of packaging for Fabri-Form Co., which thermoforms pallets in New Concord, Ohio. On the low end, plastic pallets can cost two to three times as much as wood. That’s a major obstacle, particularly if there’s no return guarantee.

Tracking is important in closed-loop pallet markets like groceries, beverages, pharmaceuticals, and automotive. In a closed loop, plastics can tighten the gap with wood on a cost-per-trip basis, especially in industries like food services and pharmaceuticals, where cleanliness is a priority.

Purchase of plastic pallets has always been viewed as a capital cost. With today’s spiraling resin costs, plastic pallets are a much harder sell, say industry observers. “Resin cost is affecting the market tremendously,” says Rick Sasse, business development manager for thermoformer TriEnda LLC in Portage, Wis. “The interest hasn’t been affected, but it’s made the justification more difficult.”

There are no firm statistics on plastic pallet manufacturing, but it is generally believed that injection molding and thermoforming are the dominant processing methods. Each of the five main processes used to make pallets has its own advantages in terms of productivity, performance, and end-use application. Injection molding uses high pressure to produce more engineered parts with complex geometries, ribs, and tight tolerances. It is a high-output process but tooling can be prohibitively costly. Structural foam uses low pressure and less costly aluminum tools. The pallet has an integral skin and a cellular core with a high strength-to-weight ratio.

Single- or twin-sheet thermoformed pallets provide light weight and modest tooling cost for low-to medium-volume production. Thermoformed pallets are nestable and are used by the U.S. Postal Service and grocery distributors. Rotomolding is typically used for large, custom, heavy-duty pallets for conveyor systems, food processing, and warehouse storage. It offers low-cost tooling but cycle times are longer. Compression molding has emerged as an attractive method that can handle the variable processing characteristics of recycled resins.

‘BLACK IS GREEN’

To combat stable wood prices and increased resin costs, processors of injection and compression molded pallets have turned to using more regrind and recycled plastics. Even in structural foam, the key to better economics is the use of recycled materials, says Russ LaBelle, president of Wilmington Machinery. He says structural foam is a “forgiving” process that accepts materials with varied melt indexes. There is also a resurgence of recyclers entering the pallet business to provide value-added service, he says.

Greystone Logistics, Tulsa, Okla., operates a plastics recycling plant and injection molds pallets from 100% recycled resin at a facility in Bettendorf, Iowa. The company uses a proprietary blend of PE and PP from post-industrial and post-consumer streams that costs up to 50% less than virgin resin, according to CEO Warren Kruger. These pallets are typically black or gray due to the recycle content. Last year, the company used 30 million lb of recycled resin to make 750,000 pallets.

Greystone’s new rackable keg pallet for MillerCoors has fiberglass rods inserted after molding. Kruger says the material blend provides equal or greater strength than virgin, and a patented polyethylene grommet provides anti-skid performance.

Another producer of injection molded pallets from recycled resins is enjoying 10% to 15% annual growth. Solplast Inc. in Montreal produces 6 million lb/month of recycled plastics at its two plants and uses low-pressure injection to make heavy-duty monoblock pallets for warehouse, pharmaceutical, food, and beverage uses. The low-pressure method produces thicker and heavier pallets with greater impact strength than high-pressure versions, according to Solplast. It is a slower process (10 min vs. 2 min for high-pressure injection) which imparts less stress on the material. Overall performance is said to be equal or greater than virgin materials, says Josie Lauzon, sales and marketing manager.

Compression molding is also well positioned in the pallet market because it handles the process variations of recycled materials. “As the green movement advances among big-box retailers, they will expect a pallet made of recycled material,” claims Clarke Howland, v.p. of sales for Composite Technologies Co., a Dayton, Ohio compression molder. “This is ideal in our world because black is green,” he says, referring to the black color of most recycled products.

Composite Technologies uses 500- to 4000-ton vertical compression units to produce grocery, automotive, and distribution pallets made mostly of homopolymer and copolymer PP recycled resins. (In a few cases, long glass is added for extra stiffness.) The company’s proprietary process (available for licensing) involves extruding a molten “log” or “billet,” which is transferred immediately to the compression press. This high-output process is as fast as high-pressure injection, producing 35-lb pallets at 55/hr, according to Howland. Unit cost is said to be 25% lower than structural foam and 40% less than thermoforming.

Another manufacturer of compression molded pallets, Granville Composite Products in Lewistown, Pa., uses a proprietary high-output process with low-cost tooling. Called ToughPrest, the process is described as “thermokinetic molding” and is designed for recycled resins. Press bed sizes are up to 9 x 6 ft. Ron Warner, v.p. of sales and marketing, sees many new market opportunities, such as bagged cement, which currently uses wood pallets.

Granville is also the U.S. distributor for Germany’s Craemer GmbH, a leading supplier of injection molded pallets and one of the first to use RFID tracking (see below). Craemer makes high-end HDPE pallets for food, pharmaceutical, automotive, and chemical applications. In a secondary operation, two RFID tags are placed inside the pallet feet. Craemer uses the RFID-enabled pallets in a new pooling system called Palpool for closed-loop manufacturing. In a recent pilot program, a German frozen pizza maker and its suppliers used the RFID-enabled pallets for work-in-process.

EXPORT PALLETS TAKE OFF

The International Standard for Phytosanitary Measures 15 (ISPM 15) requires all solid wood packaging like pallets to be heat treated or fumigated with methyl bromide, both of which add cost. Shippers of time-sensitive products are reportedly opting for competitively-priced plastic pallets to avoid potential delays in certification of wood pallets. As a result, the export market has grown significantly in the last five years, says Marty Ackerman, sales manager for wholesale distributor Plastic Pallet & Container Inc., Hudson, Ohio.

The ISPM 15 requirement makes one-way wood pallets more expensive and has generated a flood of new plastic alternatives, particularly in injection molding. An example is the Skidmarx injection molded HDPE pallet from Port Erie Plastics, Harborcreek, Pa., which has an open-deck construction and weighs less than 16 lb. The 48 x 40 in., nine-leg pallet can handle up to a 2000-lb load, evenly distributed. Injection molders Solplast and Greystone Logistics also entered the export market with 16-lb pallets of recycled resin.

A compression molded version made of recycled PP is the X-Porter from Composite Technologies. At under $10, the fully nestable pallet is claimed to be the most cost-effective export pallet. The open-deck version weighs 13.5 lb while the closed deck is 15.5 lb.

FIRST PLASTIC PALLET POOL

One of the greatest threats to wood pallets is the start of the first pooling system using RFID-enabled plastic pallets. Intelligent Global Pooling Systems (IGPS), Orlando, Fla., developed the system to compete with the wood-pallet pooling system run by CHEP, also in Orlando. Pallet pools allow users to rent pallets and return them for inspection and reuse. The IGPS system enables plastic pallets to go beyond typical closed-loop systems and maximizes their reusability. And the innovative RFID technology ensures that the expensive pallets are tracked. “Pooling makes plastic pallets viable because it’s too expensive to buy a pallet, ship it out with a load, and not see it come back,” explains IGPS CEO Bob Moore, a former CHEP executive. The average trip rental costs $6, which is competitive with wood pools.

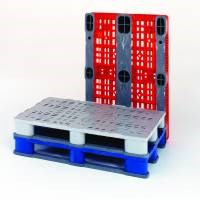

Schoeller Arca Systems of the Netherlands, one of the world’s largest plastic pallet makers, has a contract to produce 6 million pallets/yr for IGPS at plants in Morenci, Mich., and Springfield, Mo. The 47.5-lb hybrid pallet weighs 30% less than typical wood pallets and is UL 2335 certified for flame resistance. It consists of a top deck of twin-sheet thermoformed HDPE and a lower deck of injection molded HDPE. The nine-leg, 48 x 40 in. pallet is reinforced with five steel bars for edge racking, and the decks are heat welded together. The pallet sells for over $60.

“IGPS was looking for a durable pallet to offset the CHEP wood pallets,” explains Robert Engle, president of Schoeller Arca North America, Southfield, Mich. “We needed a really tough pallet that could perform better, was lighter, and could integrate RFID.”

Each pallet has a unique ID and is tracked and traced via four RFID tags that are placed in the post cavities. Static load capacity is 3000 lb and dynamic load is 5000 lb. A proprietary brominated FR formulation gives the pallet its unique fire rating. Schoeller Arca guarantees 60 pallet trips and offers a 12-yr replacement warranty. So far, only about 700 of the first million pallets have come back for repair, according to Engle. Target markets are groceries, electronics, and pharmaceuticals. Key customers include Gatorade, Dole Fresh Vegetables, Imperial Sugar, Pilgrim’s Pride, and the Chicago division of PepsiCo. IGPS has a calculator on its website intended to show how much fuel would be saved by trucks carrying plastic instead of heavier wood pallets.

In Germany, another plastic pallet maker is using RFID tags for tracking. Smartflow Deutschland GmbH has developed an RFID-equipped pallet made of recycled resin. The injection molded pallet weighs less than 20 lb and carries up to 1200 kg (2640 lb). Two passive tags are placed in the pallet feet.

NICHES STILL STRONG

Despite the latest success with recycled resins, export markets, and pooling, plastic pallets are still largely considered a niche product for sanitary and closed-loop systems due to their cost. Injection molders of pallets, such as PDQ Plastics, Bayonne, N.J., see strong growth in the food industry due to concerns over sanitary issues and food-borne illnesses. The easy cleaning and non-absorbency of plastics have had a major influence on food manufacturers the last 10 years, according to Hartson Poland, v.p. and general manager of PDQ. The firm molds one-piece HDPE pallets that cost $69 and carry a three-year guarantee.

New structural designs to lower cost and weight are being developed, according to Joe Borer, automotive market manager for injection molder Buckhorn Inc., Milford, Ohio. Injection molded and structural-foam pallets are appearing in more complex one- and two-piece designs joined with snap-fits and metal fasteners and incorporating steel or nylon reinforcements to provide edge-racking capability. While most injection molded pallets are made of HDPE, at least one company is using PP for greater stiffness. Rehrig Pacific, a leading pallet supplier to beverage companies like Pepsi and Anheuser-Busch, says a PP impact copolymer has higher flex modulus than HDPE.

Pallet injection molders are turning to multi-platen presses for greater productivity, sequential valve gating for improved efficiencies, and electric screw drives for improved cycle time, according to Mark Elsass, supervisor of applications and technology at Cincinnati Milacron.

In structural foam, there is growing use of bigger machines with multi-nozzle technology for greater output, according to Ed Hunerberg, director of Uniloy Milacron’s structural-foam machinery business. The company just shipped a 500-ton multi-nozzle SPF 500 unit to Spain for production of a plastic pool pallet. The machine is capable of both structural-foam and structural-web gas-assist molding (some pallets use both).

Uniloy Milacron also offers a 1000-ton Springfield SF1000 wide-platen, multi-nozzle structural-foam machine that can mold four 48 x 40 in. pallets in 2 min. Hunerberg says the firm is developing a structural-foam machine with a two-platen clamp adapted from Cincinnati Milacron’s Maxima injection presses. It will offer lower cost and faster cycles, Hunerberg says.

Next year, Wilmington Machinery plans to introduce a new line of structural-foam machines dedicated to pallet making in terms of shot size, plasticating capacity, and overall output, according to LaBelle. They will cost 20% to 40% less than current general-purpose machines and provide better efficiencies and cycle time with the use of robots, he says.

Single- and twin-sheet thermoformed nine-leg pallets have held a foothold in distribution for the U.S. Postal Service and the grocery market since the early 1990s. They are lightweight and fully nestable, providing attractive space savings for truckers and retailers. (Some sources say the space savings with nestable plastics are even more important to truckers than the weight savings.) TriEnda LLC, Portage, Wis., and Shuert Industries, Sterling Heights, Mich., are two of the original suppliers of twin-sheet pallets to the U.S. Postal Service. The agency is apparently reassessing its program after major difficulties in recovering its pallets.

TriEnda is a strong player in the automotive, grocery, and retail market and recently entered the export market with a one-way twin-sheet pallet made of recycled HDPE. And Shuert introduced what it says is the first all-twin-sheet edge-rackable pallet. Previously, twin-sheet thermoforming was combined with injection molding to make a pallet that could support edge racking. The new one-piece pallet weighs 10 to 15 lb, which is lighter than injection molded versions and is said to be cost-competitive. It has dynamic load capability of 3000 lb and is aimed at general-purpose use, mostly in food manufacturing.

Rotomolded pallets have their niche in heavy-duty, odd-size, custom applications. They are characterized by low-cost tooling, long cycle times, and one of the highest finished part costs among plastic pallet-making processes. Rotomolding produces durable, high-strength, one-piece parts with an average life of 15 yr, according to Jay Skinner, sales director at Stratis Corp., Indianapolis.

Rotomolding has found a home in large industrial transport pallets that carry heavy loads. Jeco Plastic Products, Plainfield, Ind., molded an LLDPE pallet measuring 117 x 54 in. for a manufacturer of truck trailers. The pallet has 0.25-in.-thick walls for exceptional rigidity and impact resistance. It also has eight steel reinforcement bars, which provide 36,500-lb static-load capability and a 24,500-lb dynamic load. A special UV stabilizer allows for outdoor use at temperatures up to 140 F.

Another large rotomolded pallet, measuring 102 x 82 in., was made for the U.S. military by Thermodynamics, Broken Arrow, Okla. The one-piece LLDPE pallet carries a 13,000-lb dynamic load and boasts broad temperature resistance from -60 F to 140 F. There is increased demand for large heavy-duty pallets beyond the typical 48 x 48 in. size, because manufacturers are looking to cut material-handling costs, says Mike Melymuk, Thermodynamics’ v.p. of sales and marketing.

ULTRALIGHT THERMOFORMING

An innovative development in single-sheet thermoforming is the new 6.6-lb Air Ride pallet from Novo Foam Products LLC, Westlake, Ohio. It’s one of the industry’s lightest plastic pallets. Most single-sheet thermoformed pallets weigh in at 12 to 14 lb. The Air Ride consists of HIPS bonded to a shape-molded EPS foam core. A patented bonding method is incorporated in the thermoforming process. Dynamic load capacity of 1500 lb is higher than for standard single-sheet pallets.

The Air Ride pallet is for limited air-freight shipments (one or two trips), primarily those originating from Asia, says Tom Bohan, president and managing partner at Novo Foam. Shippers reportedly can save about $60 versus wood pallets that weigh 35 to 40 lb. The pallets are currently being outsourced to custom thermoformers in the U.S. and Asia, but next month Novo Foam will establish a joint venture for global manufacturing and distribution.

UNCOMMON METHODS

A non-traditional method of making pallets is a unique vibrational molding process for low production volumes (typically 500 parts or fewer). The Unifuse VIM process developed by Unifuse LLC, Staatsburg, N.Y., sinters thermoplastic powders using vibration plus low heat (below the resin melting point) and no pressure. VIM can produce large parts like pallets up to 16 ft long with thick and thin wall sections, deep draws with zero draft, undercuts, and embedded reinforcements. The process generates no waste or molded-in stress.

VIM co-inventor Robert Fried has produced a pallet from two LLDPE pieces that are first molded separately and then fused together. Low-cost machinery and tooling (aluminum and wood) reportedly make VIM more economical than traditional processes like injection molding, thermoforming, and rotomolding (see Learn More box).

Blow molding has found limited commercial success due to technical obstacles. Blow molded pallets require a lot of moving mold sections and a complex layflat involving a large parison, according to blow molding consultant Robert Slawska, president of Proven Technology, Inc. The pallet’s square or rectangular shape requires rather tight radius corners and there is a tendency to form thin wall sections and excessive top flash, say experts.

In Europe, an Italian manufacturer is using extrusion blow molding to make 1000-L IBC containers and 34-lb pallets for the same containers. Since 2004, Cassina Packaging Group, Brescia, Italy, has used a single-cavity UMA 120 accumulator-head machine from Uniloy Milacron to manufacture pallets from post-industrial HMW-HDPE. They measure 1200 x 1000 mm and meet Cassina’s custom requirements but the excess weight makes them costly for general-purpose applications, according to Marco Solinas, Uniloy’s product manager for industrial applications.

Related Content

A Processor's Perspective: What's Driving Growth in Heavy-Gauge Thermoforming

Key factors for the progress are innovative materials, advanced automation and precision engineering.

Read MoreWinners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreAmcor, Berry Merge in All-Stock Deal

Move unites two complementary businesses to create a global leader in consumer packaging.

Read MoreThermoformed Container Keeps Battery Cells Safe

Despite last-minute design changes and other unexpected roadblocks, thermoformer TriEnda works with a key supplier on innovative reusable shipping container.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More