Six Rules to Keep You Out of Trouble In Foam Sheet Extrusion

Thermoplastic foam extrusion has proved advantageous to processors. But six essential rules are commonly overlooked.

Successful foam extrusion can seem like art as much as science. An optimized foam process using inert gases is a materials and energy saver with no global-warming or ozone-depletion potential. Thermoplastic foam extrusion has proved advantageous to extruders of rigid profiles, boards, and sheets, as well as cable, garden hose, and films. But six essential rules are commonly overlooked. Such oversights can discourage converters from making a go of it.

Among the many gas options are carbon dioxide and/or nitrogen, introduced via chemical foaming agents (CFAs) or direct gas injection, sometimes used in combination. These gases are generally preferred for medium- and high-density foams because they are non-corrosive, non-toxic, and non-flammable. Cost savings may result from even the modest density reductions that these gases promote. Among them are significant energy reductions possible from optimizing your extrusion process for foam.

But if you expect to casually drop in magic dust and come away with products that are lighter, faster, stronger, and all at a lower cost, you may come away disappointed and wondering what all the talk is about. If you have tried and failed to foam extruded thermoplastics, here are the key principles that you might not have been aware of and that many encourage you to try again. In this article, the focus is on chemical foaming of high-density sheet.

1. CHOOSE THE RIGHT PRODUCT FOR THE JOB

Not all CFAs meet all criteria for all polymers. The decomposition temperature of the CFA must be close to the processing temperature of the polymer. The gas must be liberated within a specific, fairly narrow temperature range and should be of adequately high volume, controllable by temperature and pressure. The gas must have time to disperse in the polymer thoroughly. An extruder with 24:1 L/D is the minimum length to allow this.

The gases released during decomposition of the CFA must have a low rate of diffusion in the polymer, so that they remain in the plastic mass long enough for it to cool and harden. No less important is a carrier resin for the CFA masterbatch that is miscible in the selected resin. In general, a processing temperature about 25-35° F above the start of the CFA decomposition will ensure complete activation and thorough dispersion, without agglomerates and irregular cell structures. Compromised cell structures can thermoform poorly, leading to weak corners and limiting depth of draw.

2. LESS IS MORE

It is commonly misunderstood that if 1% of a given CFA achieves 15% density reduction, that 2% of the same product should result in 30% reduction, but this is not usually the case. In fact, the more you add, the farther you may find yourself from your goals, as the density creeps upward. You can quickly reach a point where bubble growth is uncontrollable as it exits the die, resulting in die swell and a profile that fails to retain its intended shape.

Alternatively, the gas bubbles may grow excessively within the melt, creating open cells where closed cells are desired. The gas bubbles will then coalesce and collapse, resulting in higher density than expected or desired. Ultimately, the part won’t look or perform as it was designed to do. It’s best to determine a level of CFA that can be fed uniformly and achieve controlled performance with your equipment.

3. BELL-SHAPED TEMPERATURE PROFILE

When extruding with foaming agents under adequate internal barrel pressure, you will reduce the glass-transition temperature (Tg) of the polymer. It is often hard to convey this fact to the uninitiated, but the gasses released by a CFA (CO2 or N2) act as plasticizers, decreasing the viscosity of the polymer. For example, a non-foamed PE sheet might be extruded at 400 F across the profile. However, in a foam process, that same polymer may have a profile (from feed zone to die) of 340, 360, 380, 400, 380 F.

Take note of the “bell-shaped profile.” By feeding into a cool zone, you prevent premature foaming that would result in gas escaping out the feed throat. At zone 4, you have completely activated the CFA; and by the die exit, you are forming your sheet while already starting the cooling process. The melt temperature at the exit should be optimized to allow the expansion without distorting the shape.

4. NO BARRIER SCREWS

The screw is the primary method of pumping and transforming the resin and CFA into a homogeneous melt. Conventional screws are divided into three distinct working segments: Feed section, transition section, and metering section.

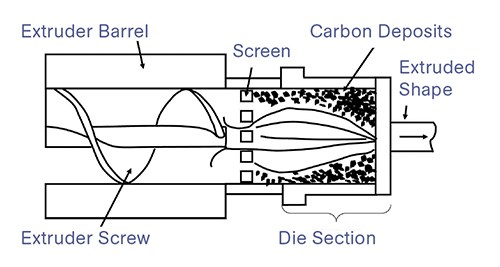

Barrier screws are sometimes employed to prevent material from flowing back to the feed section, but they will work against your foam process. The barrier will act as a decompression zone causing gas loss or early cell generation, resulting in poor density reduction or ugly blowouts on the sheet surface. Close the extruder vents for the same reason.

5. PULL YOUR SCREEN

Or at least use a coarse screen. Screen packs are usually utilized to build pressure and/or prevent agglomerates but are not usually needed in a foam process. A screen pack that is too fine can rupture cells and disrupt bubble structure. The screen can be removed entirely, but a mesh of 20/40/20 is usually acceptable if a screen must be used.

6. GET THE RIGHT DIE

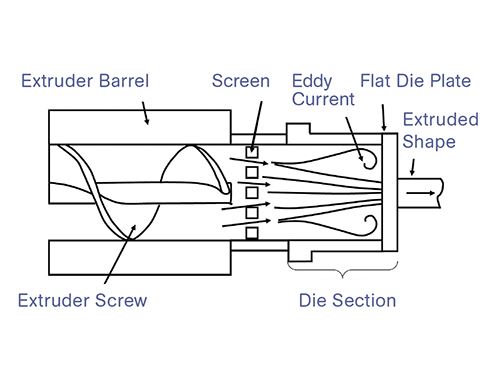

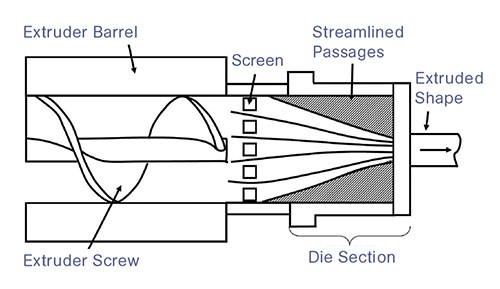

As resin is conveyed along the screw, the die design becomes the crucial component in generating high-quality foam. For sheet, a slit die is used, commonly with a “coat-hanger” manifold. In a standard, non-foaming extrusion process, the die’s primary function is to shape the extrudate after plastication (melting). But in a foam process, the die’s role shifts to preventing expansion of the foam before it exits, only guiding a general shape to be defined through a calibrator.

Foam die angles and land lengths are optimized to minimize pressure drops that would cause early foaming. A foam die exit is typically smaller than the finished part dimension, allowing it to grow outward upon exiting the die. If the goal is to achieve a 20% density reduction, the die should be 20% smaller than the intended final shape. A short die land will allow a single rapid expansion as the sheet enters the cooling phase. Adequate cooling after expansion will minimize gas diffusion and solidify the sheet in its intended dimensions.

Related Content

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More