Solve Venting Problems on Twin-Screw Compounding Extruders

Compounds must be free of voids and volatiles or else the material will cause subsequent processing problems. Here’s how to ensure your venting is effective.

Venting is one of several operations required for compounding polymers with additives and fillers in order to achieve desired physical properties. The resulting compound, in pellet form, must be free of voids and residual volatiles that would otherwise cause defects in extruded or injection molded parts.

Compounders must realize that the “customer,” a single-screw extruder, usually does not have any venting capability and that any volatiles within the pellet can only be released in the final part—leading to surface defects, holes, etc. For hygroscopic polymers that are prone to hydrolysis or degradation of molecular weight due to the presence of moisture, efficient venting during compounding is critical to achieve acceptable physical properties.

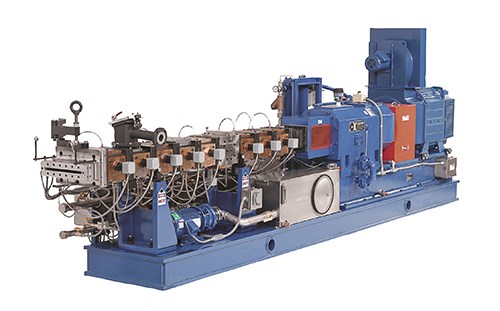

Vent openings in the extruder barrel can be operated at atmospheric pressure or under vacuum, according to the requirements of the process. Most typical compounding processes include both types of venting. Machines can be equipped with multiple vacuum vents for removal of large volumes of solvents or monomers while producing low residual volatile levels in the finished product.

A variety of vent-port designs have been developed for co-rotating twin-screw extruders to accommodate a wide range of applications and materials; these include vent stuffers, elongated vent barrels, and side vents. Each of these designs has evolved to overcome some problems associated with standard vent-port designs, which are located on the top of the extruder barrel.

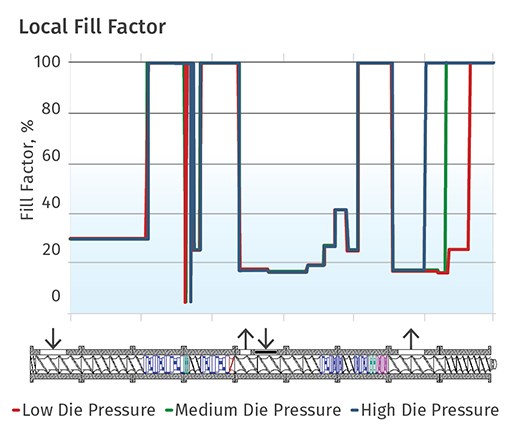

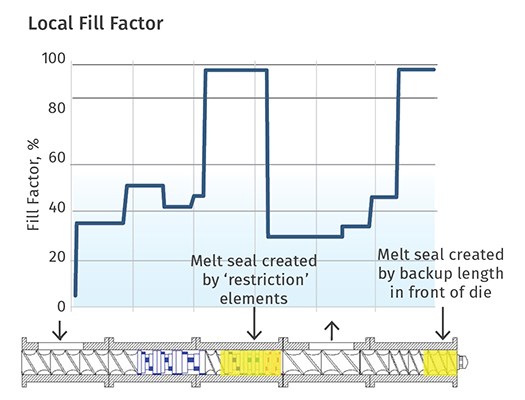

Requirements for stable operation of vents, whether atmospheric or vacuum, are a low degree of fill within the screws in the vent area and a “melt seal” (filled screw) upstream of the vent opening.

Venting problems can be divided into two categories:

1. Operational problems, whereby polymer (and/or other raw material) is coming out of the extruder vent opening(s). This process upset usually requires operator intervention to clear out vent ports or requires shutdown of the line.

2. Residual volatiles/gases remain within the compounded pellet as a result of insufficient venting within the extruder barrel. In this case, the venting efficiency needs to be improved to produce acceptable product quality.

Each of these problems has unique solutions, as described below.

WHY IS 'STUFF' COMING OUT OF THE EXTRUDER VENT?

This category of problem is very common to all twin-screw compounding extruders. Atmospheric vents are designed to release air, moisture, and other volatile gases following the initial melting of polymers. The velocity of air and/or vapors flowing out of these vent-port openings is a function of volume flow rate and the vent open area.

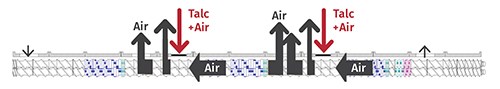

When the vapor velocity is too high (as a result of too much volume or too little open area), the exiting gases will tend to entrain solids, resulting in melt coming out of the vent opening. The solution here is to provide increased vent area and may require additional vent ports to accomplish this.

Atmospheric vents are required for side feeding of particulate fillers (talc, mineral fillers, CaCO3 , etc.) downstream into the molten polymer. These vents are designed to release the air that comes into the machine through the side feeder with the powders. The lower the bulk density of the filler, the more air is introduced into the extruder barrel that must be vented. If the vent open area is too small (relative to the volume of air that must be removed), the resulting high exit velocity will tend to carry fines and powder out of the vent. Solving this problem requires enlarging the vent area, as previously mentioned, and may also require additional vent ports.

The presence of unmelted polymer at the first side feeder also results in filler coming out of the atmospheric vent associated with that side feeder. To diagnose whether this is the cause of the problem, a physical inspection of the melt quality at the side-feeder vent must be performed to verify whether any unmelted resin is present. If this is the case, the solution requires modification of the screw design in the upstream part of the screw where polymer is melted.

Vacuum vents are usually positioned near the pelletizing die and are designed to release any residual vapors under vacuum conditions. It seems to be a very common problem that the melt will come out of the vacuum vent and block the vent opening. When this occurs, the gases are not removed from the melt, and the resulting pellets become porous with voids, etc. The vent blockage requires an operator to manually clear the vent and in some cases may require shutting down the line.

There are several possible causes and solutions for this problem: The melt may be reaching the vacuum vent as a direct result of increased backup length (the length of filled screw needed to develop the required pressure).

When the screen or die pressure increases (for example, when the screen becomes blocked with contamination), the backup length increases accordingly until reaching the vent opening in the extruder barrel. The melt will flow continuously from the vent opening even without vacuum. The solutions to this problem are decreasing the pressure (e.g. increasing screen area or number/size of die holes), increasing the pumping length of the extruder by moving the vacuum vent one barrel upstream (or adding one barrel after the vacuum vent), or installing a melt pump to pressurize the downstream equipment. Note that most of these solutions are capital intensive.

This same condition (backup length reaching the vacuum vent opening) will occur as the pumping screw elements at the end of the machine become worn. In the case of screw wear, the melt would be coming out of the vent more often over time, eventually becoming a chronic condition. The solution for worn screws is straightforward—replace the worn elements.

Melt will also flow out of the vacuum vent if the supportable pressure of the melt-sealing elements is less than the vacuum pressure. This condition results in melt being “pulled” out of the machine, since the vacuum pump is sucking air through the extruder barrel. Since there are no pressure sensors installed on the extruder barrel, the only clue that this is the cause of the problem is to watch the vacuum gauge. If the gauge is steady over time, this means the vacuum system is “tightly sealed.” If you can see the gauge dropping off, this is a sign that air is being pulled through the system (and the vent port will now be full of molten plastic). If the melt is flowing out of the vacuum port only when vacuum is applied, this is a symptom that the vacuum sealing elements are not creating sufficient pressure. Changing the screw design to use more restrictive elements for the vacuum seal is the only solution.

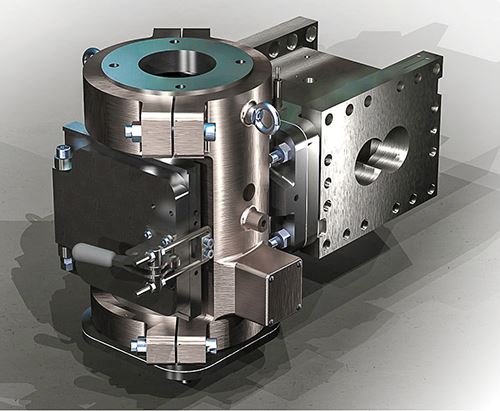

There are some specialty materials that present unique characteristics when exposed to vacuum at high temperature. Such materials tend to expand and foam upon reaching the barrel opening and will not flow readily back into the screws. These materials will come out of the machine under all conditions when using conventional open vent ports. These compounds can only be processed under vacuum using vent stuffers: mechanical twin-screw systems prevent the melt from expanding outside of the extruder screw channel yet allow for gases to move axially through the screws of the vent stuffer, which is installed within the vent opening.

WHY ISN'T MORE STUFF COMING OUT OF THE VENT?

If the current machine configuration, vent design(s), and operating conditions are not capable of removing sufficient quantities of volatiles, these solutions usually require modifying the screw design and/or the barrel configuration.

The removal of volatile gases from the melt is accomplished with vacuum to provide additional driving force for mass transfer. Most compounding lines are operated with vacuum pressure in the range of 20 to 27 in. Hg (approximately 100-300 mbar). There are many available solutions to further increase devolatilization:

• If the melt residence time under vacuum is the limiting factor (diffusion limited), one option would be to reduce throughput to increase average residence time. This is not a popular option, but is the easiest to implement.

• Another solution to increase residence time requires relocation of the melt-sealing elements farther upstream in the extruder barrel. The vacuum section is thereby extended farther upstream.

• Increasing vacuum level to maximum—this usually requires replacement of the existing vacuum-pump system.

• Decreasing the degree of fill in the vacuum section by increasing the conveying-element pitch. The lower fill in the screw channel produces thinner melt layers through which the gases must diffuse.

• Reconfigure the machine with additional vacuum vents. This can require extension of the current barrel length to add an additional vacuum vent (if there is insufficient L/D in the existing barrel to include a second vacuum-vent barrel).

• Use stripping agents (usually water) injected into the barrel upstream of the vacuum vent to reduce the partial pressure of the volatile species.

ABOUT THE AUTHOR

Adam Dreiblatt is the director of process technology for CPM Century Extrusion, Traverse City, Mich. He has more than 35 years of practical experience in processing a wide variety of materials across many industries using twin-screw extrusion. Dreiblatt has developed a series of technology training webinars for Century around the world. Contact: (231) 947-6400; dreiblatta@centuryextrusion.com; centuryextrusion.com.

Related Content

A Guide to Ultrasonic Welding Controls

Ultrasonic welding today is a sophisticated process that offers numerous features for precise control. Choosing from among all these options can be daunting; but this guide will help you make sense of your control features so you can approach your next welding project with the confidence of getting good results.

Read MoreUltrasonic Welding: Tips, Techniques, and Troubleshooting

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More