Study: Investments in Robots Create More Jobs for People

Contrary to popular conceptions, a new study finds that as industry has increasingly invested in automation, employment in manufacturing has actually risen.

The Association for Advancing Automation (A3) published those findings and more in a new white paper entitled Robots Fuel the Next Wave of U.S. Productivity and Job Growth. Using data from the Bureau of Labor Statistics and individual case studies from a wide range of manufacturing companies, the study shows that as North American investment in robots reaches record levels, companies have actually been adding to their human headcount.

“The report goes counter to a lot of the studies and reports that have been issued that give the impression that robots are job killers,” Jeff Burnstein, A3 president, told Plastics Technology. “We were hearing just the opposite; opportunities are created—better jobs, more of them, higher paying—when automation is added. We wanted to put some numbers to it.”

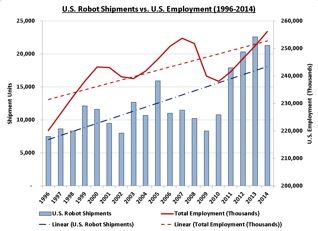

During the non-recessionary periods—1996-2000, 2002-2007, and 2010-2014—general employment and robot shipments both increased, according to the paper. Since 2010, when the robotics industry in the United States grew substantially with record-breaking robot sales, U.S. employment grew even as robots took on human tasks. “This new data is in stark contrast to media coverage and a perception that increasing use of robots causes higher rates of unemployment in the U.S.,” A3 stated in a release announcing the paper.

Burnstein said his group and the paper are not arguing a direct causation between increasing robot shipments and falling unemployment. A3 does believe, however, that the data dispels the opposite premise—more robots equals less jobs.

“If the opposite is true—robots are job killers—you’d see just the opposite on this chart,” Burnstein said, citing a graph where robots and jobs rise in tandem. “We have strong data to support our position and document how and why increasing the use of robots is associated with increased employment.”

Automation as a Bridge Across the Skills Gap

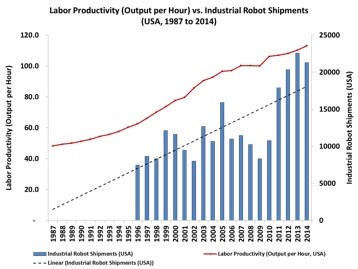

The paper asserts that as companies work to reshore manufacturing operations while remaining cost-competitive, they utilize automation to increase productivity and job growth in the U.S. “Everybody is facing the same issue around the world,” Burnstein said. “The number one threat to jobs is the inability to stay competitive.”

Thanks to rising automation and productivity in the U.S. and climbing wage rates in places like China, the U.S. has regained its competitive footing globally, but only after significant struggles. The paper, citing the U.S. Department of Commerce, noted that in the 2000s, U.S. multinationals—which employ one-fifth of all American workers—cut their domestic workforces by 2.9 million while increasing their overseas employment by 2.4 million.

This attrition was especially acute in manufacturing where manufacturing employment fell from a high of 19.5 million workers in June 1979 to 11.5 million in December 2009. Between August 2000 and February 2004, manufacturing jobs were lost for 43 consecutive months, marking the longest streak since the Great Depression, while the number of manufacturing plants shrunk by more than 51,000 plants, or 12.5 percent, between 1998 and 2008. In the 60 months going back to September 2010, manufacturing employment has risen every month save seven, rising 7% over that time.

Burnstein believes today’s manufacturing resurgence is thanks in large part to automation and that the jobs exodus in places like his home town of Detroit could have been largely averted if companies had turned to robotics sooner.

“Instead of embracing automation, companies in Detroit chose to ship manufacturing to low-cost-labor countries,” Burnstein said. Once that happened, Burnstein describes a “hollowing out” where the economic impact of a shuttered factory radiated out to the surrounding community, affecting everything from neighborhoods and schools to area businesses, including restaurants, bars, bowling alleys and more.

“If we could have kept those manufacturers running, we could have saved a lot of those communities,” Burnstein said. “I think automation could have helped in Detroit and it could have helped across the county. All those jobs we talk about reshoring now maybe would have never left the country if we had employed automation in the first hand.”

Related Content

Learn Fundamentals of Materials Handling in Self-Paced Online Course

Learn about equipment, procedures and maintenance for material handling related to injection molding.

Read MorePaulson Training Acquired

Certus, a technical skills training business and portfolio company of private equity firm Ridgemont Equity Partners, has acquired the plastics processing training business founded in 1981.

Read MoreBlow Molder with a Mission: CKS Packaging Shares Gains Of Its Phenomenal Growth

From three machines in 1986 to 27 plants nationwide today, this family-owned processor has prospered through unwavering customer service, committed employees and dedicated service to its community.

Read MoreMold-Change Time Targeted with Training, Technology

Engel is offering technology and training to molders to help them optimize their mold-changing process.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More