1st Vehicle With a Thermoplastic Composite Primary Suspension Spring

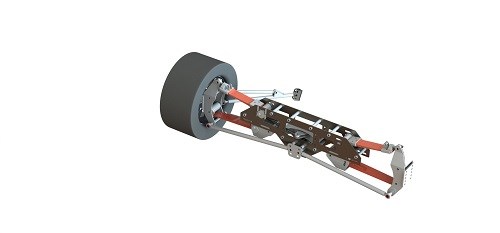

Springs and upper control arms of the Polystrand GT-Lite racecar are made from nylon 6 with continuous glass reinforcement.

Springs and upper control arms of the Polystrand GT-Lite racecar are made from nylon 6 with continuous glass reinforcement.

A purpose-built racing vehicle designed to highlight the application of thermoplastic composites in automotive applications recently competed for the first time at the SCCA (Sports Car Club of America) Majors event at the Motor Speedway Resort (MSR) Houston—a 17-turn 2.38-mile road course race track located in Angleton, Texas.

Bodied as a 1987 Honda CRX, the Polystrand GT-Lite racecar reportedly is believed to be the first motor vehicle to use continuously reinforced thermoplastic composites as the primary suspension springs. “We strongly believe that reinforced thermoplastics offer an excellent opportunity in automotive lightweighting applications due to their ease and speed of processing, and offer a cost-effective, recyclable alternative to current materials,” says Ed Pilpel, president of Polystrand Inc., Engelwood, Col.

Here are some key details to this apparent milestone. The springs and upper control arms of this multi-link independent rear suspension system, which was designed by Polystrand senior engineer Jonathan Spiegel, are manufactured from nylon 6 and are reinforced with TufRov 4510 continuous E-glass from Pittsburgh-based PPG Industries.

The prototype springs were compression molded from Polystrand continuously reinforced thermoplastic tape at the Materials Processing and Application Development Center at the University of Alabama, Birmingham School of Engineering. Also featured on the car is a reinforced PP front splitter, which is an aerodynamic aid, and hybrid interior sandwich panels made of reinforced PETG thermally bonded between thin layers of aluminum and stainless steel, manufactured in-house at Polystrand utilizing PPG TufRov 4588 reinforcement.

“While we experience several teething problems in this first outing, chasing minor electrical and braking problems during the event that prevented us from finishing the races, the suspension system performed beyond expectations, allowing us to maintain a second place positon while on the track. The MSR track is known for being rough, so this was a good test of the suspension’s compliance. Handling balance was very good, and the car maintained excellent traction at high speeds even over the notoriously bumpy pavement.”

Want to keep abreast on the latest developments in automotive lightweighting enabled by thermoplastics composites? Do so by Registering for our second presentation of “Thermoplastics Composites for Automotive” (TCC Auto2016) conference on June 15-16 at the Suburban Collection Showcase in Novi, Mich. TCC Auto2016 is presented by Plastics Technology magazine and CompositesWorld, sister publications within Gardner Business Media, and will be concurrent with the Amerimold 2016 show and conference, presented by Gardner’s MoldingMaking Technology magazine.

Read more about applications and materials TCC Auto 2016

Read more about machinery and processes at TCC Auto 2016

Read more about carbon-fiber reinforced PP compounds at TCC Auto 2016

Related Content

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

-

Prices Up for PE, ABS, PC, Nylons 6 and 66; Down for PP, PET and Flat for PS and PVC

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.