EXTRUSION: Barrier Screws and Mixers

For some reason, there are a lot of barrier screws in operation with high-shear mixers, when a distributive mixer is usually a better choice.

There are many types of mixing devices used on single-screw extruders. They are differentiated by either being primarily a dispersive or shear device that adds to the melting capacity, or a redistribution device that mixes essentially by dividing the melt numerous times to distribute the minor component as layers throughout the major component. All mixers necessarily have some of both features.

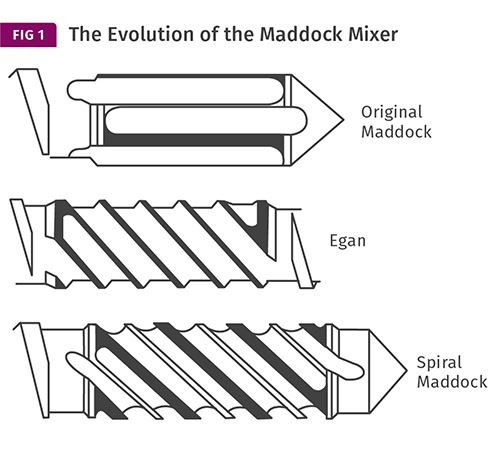

The use of these mixing devices affects the overall performance of the screw. Shear mixers, the most common of which are referred to as Egan and Leroy mixers, date back to the late 1960s. The Leroy mixer is more commonly known as the Maddock or UCC mixer because of extrusion legend Bruce Maddock’s work with it while at Union Carbide Corp.

More recently, a spiral Maddock mixer has been developed that includes features of both designs, and seems to be the most widely used today (Fig. 1). Much has been written about these mixers so there is no need to review them again here.

The Egan and Maddock mixers were initially developed to improve the melt quality from conventional screws (non-barrier). They were used to process many different polymers in a variety of applications but saw their real worth in processing crystalline polymers, principally polyolefins. They received almost immediate acceptance in the market by virtue of the fact that they greatly improved both output and melt quality.

In 1961, before these mixing sections were introduced, a barrier screw design for rubber processing was developed by Geyer at Uniroyal. Soon after, its concept of melt/solid separation was tried in thermoplastic polymer processing, and within about 10 years barrier screw became the state of the art. Barrier screws eliminated the need for the supplemental mixers, as melting could be controlled and completed in the barrier section with no need for the high-shear mixers.

Yet even today, there are quite a few barrier screws equipped with high-shear mixers, when their need has theoretically been eliminated from barrier screws. I find this puzzling.

If designed properly, once material passes through the barrier section on these screws, it should be completely melted. In most cases, adding a dispersive or shear mixer after a barrier section would needlessly increase the melt temperature, reduce the output because of the added pressure drop, and result in greater energy requirements during both the extrusion and the subsequent cooling processes. Most of the time, a distributive mixer would be a better choice to homogenize temperatures, colors or additive distribution while providing minimal additional increase in melt temperature and reduction in output.

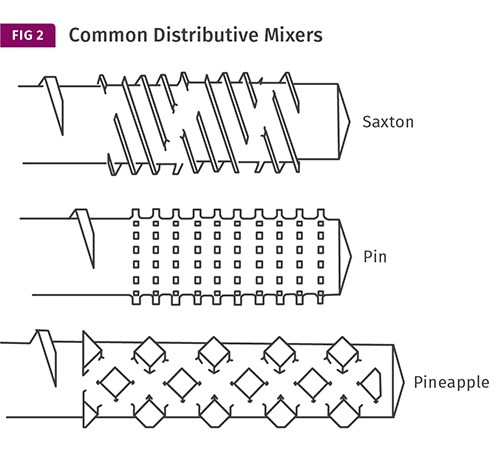

There are many types of distributive mixers, and their selection depends on the properties of what is to be mixed, the proportions of each component, and the screw L/D. A few of the more common distributive mixers are shown in Fig. 2.

The Saxton style provides mixing by dividing the melt into a number of channels, while interrupted flights allow mixing between those channels. But basically, this design relies on the same mixing principles as those in the metering section, and is most effective primarily for thermal homogenization. The advantage of the Saxton is it can be designed for very low pressure drop.

Pin mixers can divide the melt many times, creating essentially exponential divisions based on the number of pins and rows. Mixers of this type minimize the restrictions of laminar flow in mixing and can mix materials of substantially varying viscosity by creating an infinite number of layers. Their disadvantage is that they can create a substantial pressure drop.

Pineapple mixers divide the melt like pin mixers, but converge the divisions at various angles for chaotic mixing. They are very useful in when adding color.

Regardless of the type mixer chosen, the distributive types seem to fit the needs of barrier screws better than the dispersive shear-type mixers, except in cases where there is a specific requirement for intensive shear of particles small enough to pass through a barrier section unrefined.

Related Content

Optimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.jpg;width=70;height=70;mode=crop)