INJECTION MOLDING: Scientific Molding Gone Wrong

Sometimes molders get trained in Scientific Molding only to revert to their old way of doing things as soon problems pop up.

I have seen a lot of processors try to implement forms of what is generally considered Scientific (or Decoupled) Injection Molding. Regardless of how you label it, Scientific Molding requires conducting a number of experiments that are intended to provide the data needed to identify an optimal or ideal process. The concept is great: Use data to support your process settings, the more the better. Standardized process development is absolutely the way to go about developing your processes.

I visit these companies and review their process development, and most of the time it is rigorous. The correct experiments are being performed, nominal processes are established, tooling corrections are done and … they still struggle in making parts.

What? How is that possible? After all, they told me, “All the rules were followed, and I even have a viscosity curve.”

Usually, what’s happened is that the production floor made the first few runs using the parameters established during the scientific process development—without success—and then reverted back to tweaking the process each time to get parts to the customer. This causes a chain reaction, and soon those experiments are no longer conducted and process development becomes an endless circle of “try this” and tweaks until the molder can process around as many roadblocks as possible. There is no more buy-in to standardized process development, and the perception sets in that it’s just a waste of valuable time.

What really happened here? Well, often there is no need to look further than the machines being utilized. Attempting to develop a process on a molding machine that is not repeatable or is limited in any way can result in the situation I described above. So often we hear about variation in materials and how the processes need to be able to compensate for that variation that we forget that variation comes from each piece of the puzzle. I would argue that a molding machine can provide as much variation as the materials we run on a regular basis.

There are a lot of benefits to a systemic approach to process development. If done properly, it will provide you the opportunity to not only help qualify a new mold, but also can be used as a machine verification. Keep in mind that it is important to understand your machine and how it functions. Process outputs might not always be what they seem.

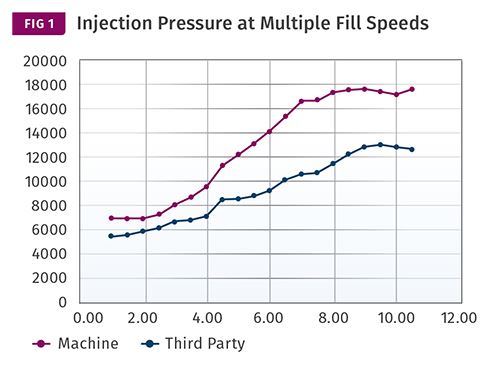

For example, a medical molder I visited recently was installing a third-party process-monitoring system, and noticed that the redundant pressure transducers were providing injection-pressure data significantly different from the output on the machine controller.

After much back-and-forth with the suppliers of the press and the process-monitoring equipment, the molder was made aware of the fact that the machine did not have a transducer at the injection unit. The transducer was located at the pump and the output was essentially the system pressure at injection (see Fig. 1).

Why is this so important? Keep in mind, this was a medical molder that validates the “process,” not just the part, to its customer. If the molder were to move away from using machine outputs to verify the process to a paperless system with third-party process monitoring, it would appear to the customer that the process was changed. This would also affect the molders’s ability to recognize a pressure-limited situation during injection.

Another example is residual pressure. Many machines have an issue with residual pressure, meaning that a setpoint of zero is truly not zero. Some machines are much worse than others, having several hundred psi (hydraulic) of residual pressure at a zero setpoint. Let’s say you didn’t know this and were trying to establish a process with a cutoff of 95% fill. This residual pressure is actually influencing how full your part is.

Once you have completed your transfer study, your part might be filling at 60% on first stage, and pack/hold is now completing your fill. This will directly affect your process’s ability to compensate for variations.

Test this on your machine by reading the manual pressure gauge during the pack/hold stage with the setting at zero. It is easy enough to eliminate this variable for process development by setting your pack/hold time at zero—just don’t forget to add that time onto your cooling. Once you have completed your study, add the time back to the pack/hold and remove it from the cooling. As stated, it is easy enough to process with this condition, as long as you know it exists and the hold pressure needed is less than the residual pressure. Then you may have a bigger issue.

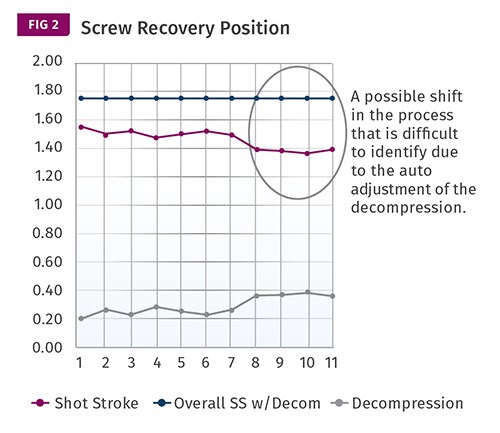

Last example: There are machines that will give you the exact screw-retract position on each and every shot. Sounds good, right? Well, these machines sum up your shot-size setting and your decompression (suckback) setting to determine what your overall shot size should be each shot. So if you have a shot-size setting of 1.50 in. and a decompression setting of 0.25-in., the machine will make sure that each time your recovery and decompression are completed your screw is sitting on 1.75 in. This means that if for whatever reason your recovery over-traveled or under-traveled the decompression is used to compensate for any inaccuracies of the recovery.

When you look at the overall screw-retract position on the machine controller, the repeatability appears to be “perfect.” The big issue I have with this is that it can mask a real problem with the screw recovery. You may have significant amount of variation in the screw recovery, but it will be difficult to identify, due to the compensation of the decompression to ensure the screw end position is identical on every shot. Remember that decompression may be ensuring that the screw retract position is the same, but that doesn’t mean the volume of material in the barrel is identical each time (see Fig, 2).

It’s important to understand your equipment and how it functions to ensure the repeatability of your process. I often work with molders that have no idea what their intensification ratios are or understand the concept of a Delta P to prevent pressure-limited processes. Without this knowledge, how can one be successful? Short answer: You can’t.

So how does one get to “know” their machine? This question has a two-part answer. The first is a simple one: By running it. Of course, working side by side with a technician from the machinery manufacturer will help expedite your ability to run a new machine; nothing will replace putting your hands on the machine control. Challenge the capabilities of the press and perform some cause-and-effect studies. More simply, find out what happens when you change this setting or that. How does the machine react?

The second answer is where it gets a bit more difficult—especially if you don’t know what to look for—and that is analyzing the outputs of the machine. Once you become proficient and know what to look for when reviewing this data, you may start to notice that the outputs on some machines are not always as reliable as you might think. Don’t forget our examples above. That’s why it isn’t a bad idea to use these third-party process-monitoring systems, and at the very least have one unit for process development and machine verification.

Remember that all setpoints on your machine have an output associated with them, and none of them are 100% accurate. Some setpoints will affect multiple outputs.

Understanding how much the machine varies from shot to shot versus the setpoint is the basis for understanding whether your machine is repeatable. Reviewing the machine and the cavity-pressure curves to understand how quickly your machine can react to changes is also crucial.

Lastly, it’s important to ensure that your machine is running the same now as it was six months ago. Some of us in the industry use the term “calibrated” when it comes to this topic, but technically this is not an official calibration. Although some machine manufactures offer calibration programs, they are typically just processes that return the machine to the factory conditions. A re-zeroing of the pressures would probably be a more fitting term.

Either way, this is significant. If ideal pressures are not the same as they were when your processes were developed, matching outputs will not provide the same part as they did back then. This is the detail that really makes the production group doubt what they are trying to do. The technicians on the floor will match the outputs established by the engineering group, yet the parts are different. This is where tweaking the process gets reintroduced into the culture of the operations group.

At the end of the day, they still need to provide the customer with parts and there is no way anyone is shutting down an automotive OEM. This cannot be ignored if you truly want to continue a systematic approach to process development and Scientific Molding. As I stated above, most machine manufactures will have some sort of “calibration” program that should be completed annually. I cannot stress this one enough.

Our job as molders is to mitigate the risk of producing bad parts to ensure our companies can be profitable. To accomplish this, we need to isolate and understand all forms of variation that are introduced into our process. Variation comes from every aspect of what we do, and understanding where it comes from, and mitigating its effects on the part, is the foundation of a robust, repeatable, process.

Related Content

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More