Extrusion: Where's the Data? The Importance of Melt Strength in Extrusion

All extrusion processes depend to some degree on the melt strength of the polymer, and this property is generally a no-show on data sheets.

There is an important data point for extrusion-grade polymers that is almost never found in the data sheets. Spec sheets typically show the solid density, melt flow, and a variety of physical properties of the solid polymer. Many even have some thermal properties that are necessary for screw design and cooling calculations. But all extrusion processes depend to some degree on the melt strength of the polymer, and this property is generally a no-show on data sheets.

That’s unfortunate because this data point is vital. In the case of sheet, melt strength is important to know because it influences drawdown and sag from the die to the rolls. With film, melt strength impacts bubble stability and the ability to draw the film in the machine and transverse directions (MD, TD) to get balanced properties. For blow molding, melt strength influences parison sag to control wall thickness. For pipe and profiles, it impacts drawdown and sag for orientation and concentricity. Melt strength also affects drawdown in extrusion coating. Even in coextrusion applications, a relative balance of melt strength can help achieve interfacial stability.

On Your Own in Determining Melt Strength

The problem is that processors generally have to determine melt strength on their own and try to compensate for it by adjusting melt temperatures, output rates, equipment design, and the time interval between when the polymer is in tension or an unsupported state. This can be an expensive and time-consuming trial-and-error process, often requiring significant equipment changes.

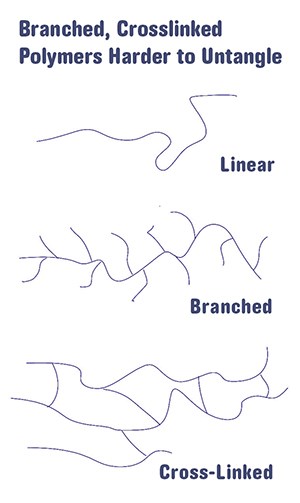

Melt strength can be described as the resistance of the polymer melt to stretching. The melt strength of a material is related to the molecular chain entanglements of the polymer and its resistance to untangling under strain. The polymer properties affecting the resistance to untangling are molecular weight, molecular-weight distribution (MWD) and molecular branching. As each property increases, melt strength is improved at low shear rates.

Branching and MWD have the most significant effect on melt strength while maintaining processability. The branched polymers (or those with a larger proportion of very long molecular chains) require greater strain to untangle the molecules and permit them to flow. Linear polymers are simply long polymer chains with little or no branching, and are more easily untangled when a strain is applied.

Crosslinked polymers act similarly to branched polymers, and there are many commercially available additives for linear polymers that crosslink the linear chains to improve melt strength. Moreover, modern polymerization technology has allowed branching of some polymers that normally would not be branched.

For extrusion processors that change polymers frequently, it can be very helpful to have some indication of the melt strength of the material beforehand to anticipate operating conditions and make the necessary equipment changes

Melt strength is also related to the extensional viscosity of the polymer, which can be determined by convergent-flow rheometry. But the two are not always proportional, so extensional viscosity alone does not describe melt strength. Melt strength is even less closely related to traditional shear viscosity measurements, so that melt flow/melt index measurements are not a significant indicator of melt strength.

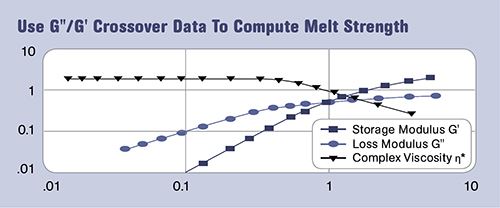

A variety of methods have been developed to measure melt strength as it applies to practical extrusion. The main one has been the Goettfert Rheotens device where a molten extrudate or fiber strand is pulled between two powered rollers as it leaves a downward-extruding orifice. As the speed of the rollers is increased, tension is created in the strand, which is measured by the Rheotens device. The loss modulus (G") and storage modulus (G') crossover as measured on an oscillatory rheometer has become useful for estimating melt strength.

Oscillatory rheometers are widely used today for polymer characterization. Data can often be obtained directly from suppliers with no additional testing needed, as the materials companies often use these rheometers for internal quality control. The information would be displayed in a graph; the lower the crossover point of the G" and G' lines on both the horizontal and vertical axes, the greater the melt strength.

For extrusion processors that change polymers frequently, it can be very helpful to have some indication of the melt strength of the material beforehand to anticipate operating conditions and make the necessary equipment changes. Different melt strengths almost always require die changes to compensate for drawdown differences, but they can also necessitate more elaborate changes in equipment for other effects of melt strength.

About the Author Jim Frankland is a mechanical engineer who has been involved in all types of extrusion procesing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreRead Next

Melt Fracture or Interfacial Instability? Different Ills Needs Different Cures

In blown film, clarity is often considered synonymous with quality.

Read MoreWhat You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

.jpg;width=70;height=70;mode=crop)