Working with Color Concentrates

Industry needs more development of enhanced-mixing screws.

In the late 1950s the reciprocating screw was introduced to the plastic processing industry. It represented a significant step in achieving a greater level of homogeneity in the melt over the plunger machines that had been the standard in the industry. The ability of the screw to generate significant levels of mechanical work was a key part of this advance. Over the ensuing five decades the extrusion industry has made additional strides in improving melt uniformity by using different types of mixing elements and employing greater L/D ratios.

In the meantime, the injection molding industry has remained largely stagnant in this area. Some high-intensity devices such as Dulmage and Maddox mixers, which generated levels of shear that were appropriate only for very robust polymers like polyethylene, were developed in the 1960s (the Dulmage patents actually date back to the 1940s). Work was done in the 1970s with developments such as the zero metering screw in an effort to improve on the standard model. In addition, the arrival of the vented barrel had the unintended consequence of improving mixing through more intense shearing of the melt. And perhaps ironically, the two-stage screw-and-plunger model that has seen various incarnations from the early 1960s through today also achieves a greater degree of melt uniformity while attempting to improve on shot control.

However, for the most part, the injection molding industry remains stuck with what has come to be called the general-purpose screw, or as famous screw designer Bob Dray puts it, the “no-purpose screw.”

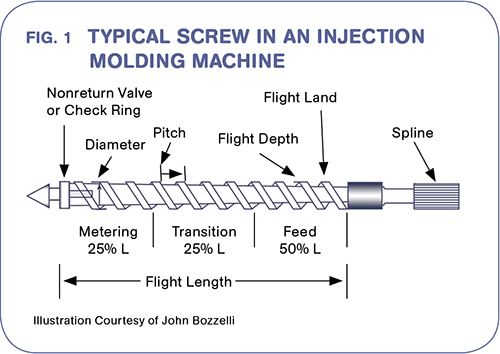

This design consists of some typical features as shown in Fig. 1. These include a particular ratio of the length for the feed, transition, and metering zones, and a ratio in the depth from the flight to the root diameter of the screw, known as the compression ratio, of approximately 2.5:1.

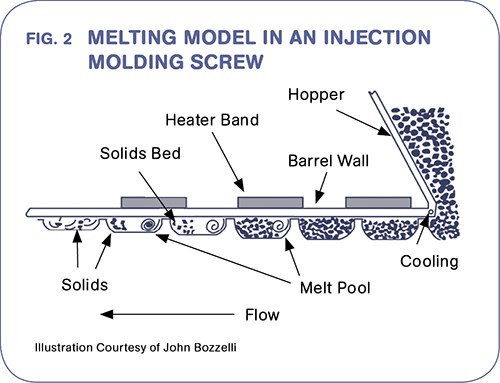

Optimization of this design for various materials typically consists of decreasing this compression ratio for materials that are considered to be shear sensitive, such as PVC, and increasing it for materials that are difficult to melt and benefit from increased levels of shear, such as acetal. But these adjustments do not address a fundamental problem with the general-purpose design, shown in Fig. 2. The standard design conveys solids forward through the feed zone, begins to create a melt pool in the transition zone as the pellets are thermally and mechanically softened, and ideally achieves a completely melted and homogenized system by the time the material reaches the front of the metering zone.

Unfortunately, it does not always work out this way. Instead, as the polymer reaches the front of the screw, the remaining solids become dispersed in the melt, making it very challenging to complete the melting process. This results in the frequently observed problem of unmelted pellets in the molded parts. We even have a term in the industry for this condition: “unmelt.”

Another symptom of this poor level of homogeneity is color swirls in parts where mixtures of natural resin and color concentrate are used. This problem is particularly noticeable in high-viscosity polymers such as ABS and polycarbonate. It is this shortcoming in the ability of our injection units to mix and melt the polymer that leads to the misguided use of incompatible carrier resins and very low-molecular-weight polymers in color concentrates. But this approach does not address the root cause of poor mixing.

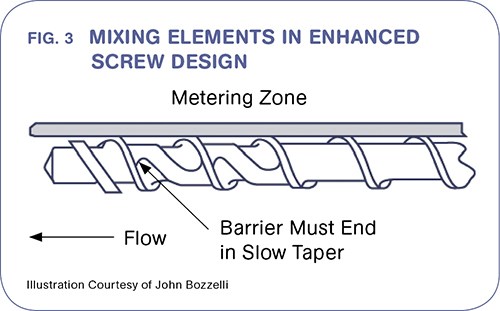

In the early 1990s, when ABS resins became clean enough to provide a consistent base color, the opportunity arose to use color concentrates rather than rely on fully compounded materials that were costly and involved long lead times. Initially, however, molders struggled with melt uniformity. Working together, researchers at resin companies and development engineers at companies that designed and built screws created improved designs that addressed this fundamental flaw in the general-purpose design without introducing the damaging effects of high-intensity mixing elements.

An example of such a design is shown in Fig. 3. By incorporating a dual-depth configuration in the metering zone, any material that was not melted was allowed to remain in the melt stream for further gentle agitation rather than being forced forward into the shot. This variation on the barrier screw design had dramatic effects on the melt uniformity that included elimination of color swirls in natural-plus-color-concentrate systems without the use of elevated melt temperatures or high backpressures. In 1991, after seeing an SPE ANTEC presentation by consultant and fellow Plastics Technology columnist John Bozzelli, we purchased such a screw.

At the time, our machine was running a housing in multiple colors of acetal homopolymer using natural plus color concentrates. The concentrates were also based on an acetal resin with a slightly higher melt flow rate. We struggled with color swirls and unmelted pellets.

In an effort to remedy these issues, we ran melt temperatures that were on the verge of degrading the polymer and we employed very high backpressures that extended the cycle due to a longer screw recovery time. Even with these extreme measures, our reject rate was over 6% and every three weeks we had to pull the screw and clean the carbonized resin from the corner radii where the vertical wall of the flight blended into the root of the screw. In addition, an exhaust hood had to be installed over the mold to vent the formaldehyde that was generated by the elevated melt temperatures.

When we put in the new screw the melt temperatures were reduced by 60° F and the backpressure came down from 300 psi to 75 psi hydraulic. The problems with color incorporation and unmelt disappeared; the cycle time was reduced; and the periodic screw cleanings stopped. The screw paid for itself in seven months and started a revolution within the operation that eventually saw general-purpose screws replaced with mixing screws throughout the plant. The number of “material problems” and “processing problems” that simply disappeared was a revelation. And it taught us that resorting to ill-advised material-selection strategies when specifying color concentrates was not only poor practice but unnecessary.

Unfortunately, little has changed 20 years later. Most new molding machines still incorporate a general-purpose screw that does a poor job of creating a homogeneous melt. This lack of homogeneity produces a very large number of molding problems as well as difficulties that are blamed on the raw materials. Machine builders have done very little to investigate the newer screw-design technologies and provide them as at least an option within their product offerings. Consequently, many processors continue to struggle with defects caused by poor melt uniformity, or they opt for using more costly fully compounded materials.

This lack of advancement also hampers processors who are attempting to incorporate other ingredients into their materials at the press, such as reinforcing fibers and additives. But adjusting the formulation of the concentrate does not directly address the problem and in the end often does more harm than good. Happily, there are remedies if processors are willing to venture beyond the standard screw and barrel offerings provided by their machinery suppliers and work with the independent firms that have been improving on the standard designs.

Related Content

Riverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Read More'Dual Action' Purging Compound Accelerates Color Changes

NPE2024: Shuman Plastics’ Dyna-Purge Division launches Dyna-Purge L, extending its “3X technology.”

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreTechmer Buys Advanced Color Technologies

Deal will expand Techmer’s in colorants and additives in synthetic fibers.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

.jpg;width=70;height=70;mode=crop)