Your Extruder's Best Friend

That's the melt pump, and its main purpose is to precisely control output to the die.

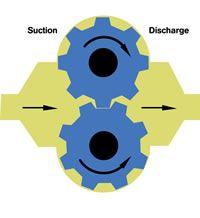

That's the melt pump, and its main purpose is to precisely control output to the die. Melt pumps consist of two gears, usually driven by a single motor. The extruder fills the gears from the suction side (see diagram), and the rotating gears discharge the polymer on the other side. The principle is that a well-made gear will have a very accurate profile, and when that gear is enclosed in a tight-fitting housing, the volume of plastic in each tooth will be very precise. As the gears turn they meter an exact amount of plastic on the discharge side. The speed of the gear rotation is closely controlled by an AC or DC drive designed for less than 1% variation.

Why is the melt pump your extruder’s best friend? By precisely controlling the output of melt it eliminates many of the variables that impact extruder throughput stability. The pump compensates for such things as poor or erratic temperature control, feed interruptions, changes in the polymer mix (i.e., varying amounts of regrind) and surging due to imprecise screw design. With many output stability problems out of the equation, the operator is free to focus on the die and downstream equipment.

MONITORING THE PUMP

However melt-pump performance must be monitored to some degree. The important things to observe are discharge and suction pressures, the difference between those pressures, motor amps, seal leakage on the gear shafts, and pump temperature.

The discharge pressure should be constant, as the die flow will vary proportionally with changes in discharge pressure. I like to see the discharge pressure vary no more than ±10 psig. Variations greater than that generally can be traced to a drive issue, requiring a motor technician to adjust drive parameters. A severely worn pump can also cause such a problem.

Suction-pressure variation mirrors the extruder’s output variation. Although the main purpose of a melt pump is to remove these variations, there are limits to how much variation it can control. Even though the pump will continue to discharge a constant volume of polymer, melt temperature will vary as the screw changes speed to try to maintain constant suction pressure. The changing melt temperature will cause variations in die flow and part geometry.

I like to see no more than ±100 psig variation in suction pressure, and preferably ±50 psig. If the variation is greater than that, there will be changes in die flow. Often this requires nothing more than desensitizing the extruder motor’s response to pressure variation. This can usually be achieved by increasing the proportional control and the bandwidth of the pressure instrument controlling the extruder motor. If that does not minimize the variation, the problem is likely in the extruder itself and will have to be analyzed.

The power required to turn the pump gears should be very constant. Variations of more than several amps in the pump drive indicate a problem. It could be simply a drive parameter setup issue; a mechanical problem developing in the pump, gearbox, or drive shaft; or too much variation in the suction pressure.

LUBRICATED WITH MELT

Melt pumps have bearings that are lubricated by the melt itself—there is designed leakage from the discharge of the pump to the suction side through the bearings. That flow of polymer is necessary to maintain the life of the bearings. Such flow requires a pressure difference between discharge and suction. It is advisable to maintain at least several hundred psi difference between the two.

Since the melt pump’s bearings are lubricated by the melt, the seals outside the bearings stop the flow of polymer out around the gear shafts. To accomplish this with different melt viscosities and pump pressures, most pumps are equipped with water-cooled seals. In this case, the proper adjustment is to apply just enough water to stop or reduce the leakage to a tiny amount. Additional water tends to reduce lubrication of the bearings and add motor load to the pump drive.

The temperature of the melt pump after startup should closely match the melt temperature of the polymer and/or the melt-temperature setpoint. If pump temperature is well above the setpoint or actual melt temperature, there is something wrong with the mechanical parts of the pump or the temperature-control instrumentation. It’s good practice to set the melt pump 5° to 10° F below the melt temperature.

A MULTIPURPOSE DEVICE

The melt pump provides several other important advantages in addition to discharging a constant volume of polymer. It is a more effective device for raising pressure than is an extruder screw. As a result the head pressure on the screw can be reduced, lowering the melt temperature and increasing the screw’s output. The melt pump is also a mixing device and thereby improves melt quality.

If you take good care of your extruder’s best friend, you’ll find it will return the kindness tenfold.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

The Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreThe Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)