Resin Conveying

Resin conveying includes central conveying; material handling; vacuum conveying; pneumatic conveying; transferring resin; angel hairs.

ESSENTIAL READING

VIEW ALLFollow These Steps to More Efficient Central Pneumatic Conveying

Depending on when you bought and installed it, there are ways to tweak your central pneumatic conveying system to improve its performance and save you some money.

Read MoreHow to Maximize Your Conveying System Performance

If your conveying system isn’t up to snuff, and you don’t have the budget to overhaul or expand it, don’t lose hope. There are many factors that could be limiting your conveying performance, and a number of them cost little or nothing to fix.

Read More10 Things to Know When Specifying Vacuum Conveying Systems for Powders

The priority is to maximize movement of powders while minimizing dust exposure.

Read MoreHow to Choose & Use Metal Separators

Use of magnets for removing ferrous contaminants in an industrial environment began in the 1940s to help farmers trap and remove metal contaminants from their grain chutes.

Read MoreHow to Set Up & Maintain An Efficient Resin Handling System

In today's world, having a reliable resin-handling and conveying system is as important as having reliable electrical power.

Read MoreHow to Minimize Problems With Gravimetric Blenders

The first and best way to avoid blending problems is to choose the right gravimetric blender for the application.

Read MoreLatest Resin Conveying News And Updates

IoT Upgrade Enables Vacuum System Monitoring

The system upgrades enable the monitoring of multiple vacuum generators and the supervision of the production process to ensure that it runs reliably and with the correct levels.

Read MorePiovanGroup Announces Transition In Leadership In North America

John Erkert ascends to Regional CEO position for North America as industry veteran Kirk Winstead retires.

Read MoreNew Pump Rewrites Conveying Rules

NPE2024: Smart Pump technology brings more flexibility and finesse to resin conveying.

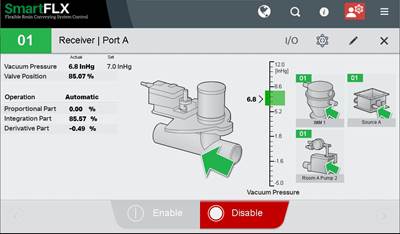

Read MoreArtificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.

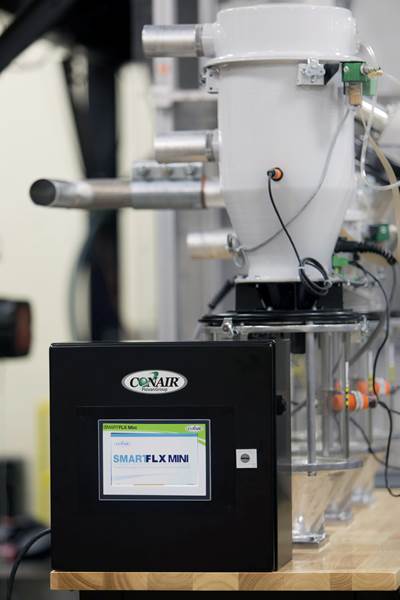

Read MoreMini Control Offers Central Conveying for Small Plants, Work Cells

NPE2024: System supports vacuum conveying systems with up to three vacuum pumps and a maximum of up to 12 receivers.

Read MoreResin-Selection Station Conveys Material on Demand

NPE2024: Powerful, space- and labor-saving station makes the connections and conveys material automatically on command.

Read MoreFeatured Posts

Deflection Elbows Eliminate Streamers for Large Film Processor

New elbows eliminate troublesome streamers to increase productivity at leading blown film processor.

Read MoreTechnology Aims to Smarten Up Resin Conveying

At NPE2024, Novatec moves to rewrite the rules for material conveying with patent-pending smart-pump technology.

Read MoreConair: Going All In on AI

Conveying with Optimizer, Conair’s new AI-based conveying technology stands to be a true game changer for plastics processors.

WatchNovatec Putting the ‘Smart’ In Resin Drying, Conveying

NPE2024: Machine builder gets ‘ludicrous’ by rewriting the rules for material drying and conveying.

Read MoreSafety, Recycling, and Compounding Trends Bring New Opportunity to 70-Year-Old Company

NPE2024: Vac-U-Max presents pneumatic conveying solutions for powdered materials.

Read More‘Digitalization’ – Awkward Term for a Vital Concept

At K 2022, 85 machines from 40 companies showed off their Industry 4.0 capabilities via OPC-UA interface. A new universal interface for Material Supply Systems was revealed at the show.

Read MoreFAQ: Resin Conveying

How to prevent streamers?

-

Adjust solids-to-air ratio with bleed off value

-

Cool the pellets more

-

Streamer screener

-

Air-to-air heat exchangers

-

Specialty elbows and shot pinging

-

Change the transfer system

Resin Conveying Supplier Categories

- Cellulose Acetate Propionate

- Starch-based Polymers

- Nylon--Type 6

- Polycarbonate/ABS Alloys

- PVC--Dispersion and Blending Resins

- PPE/Nylon Alloys

- Cellulose Acetate Butyrate

- Polyester (Thermoplastic)--PETG Type

- Conveyors (parts-handling)

- Polyethersulfone

- Adhesion-Modified HDPE

- Polyphthalamide (PPA)

- PVDC--Coating Grades

- Polyphosphonate

- Other Styrene Copolymers

- Acrylic/PVC Alloy

- Polycarbonate/Polyester Alloy

- PVC--Flexible Compounds

- Polyester (Thermoplastic)--PCT Type

- Desiccant for Dryers

- Thermoplastic Elastomers--Polyamide Type

- Polyamide, Aromatic

- Nylon--Type 69

- Ionomers

- Liquid Crystal Polymers

- Ethylene Plastomers

- Nylon/Polypropylene Alloys

- Nylon--Type Mxd6

- Ethylene Vinyl Alcohol (EVOH)

- Polyester (Thermoplastic)--PBT Type

- Conveying Equipment (pneumatic and Mechanical)

- Polyarylether

- Styrene Maleic Anhydride (SMA)

- Prepregs (thermoplastic)

- Metal Detectors, Separators

- Stacking, Packing Equipment

- LLDPE

- ASA Copolymers and Alloys

- Nylon/Abs Alloys

- Polyarylate

- Silos

- Polybenzimidazole (PBI)

- Polysulfone

- Cyclo-olefin Polymers

- PVC--Rigid Compounds

- Valves, Gates, Diverters

- Thermoplastic Elastomers--Olefinic Type

- Polyester (Thermoplastic)--PTT Type

- Nylon--Type 610

- PVC--Chlorinated PVC (CPVC)

- Thermoplastic Elastomers--Urethane Type

- PHA, PHBV Biopolymers

- Polyphenylene Sulfide (PPS)

- Nylon--Type 612

- Adhesion-Modified LDPE

- PPE/PP Alloys

- Polyester (Thermoplastic)--Other Types

- Ethylene Vinyl Acetate (EVA)

- Acrylics

- Hoppers, Bins, Tanks

- Polystyrene

- SAN

- Cellulose, Ethyl

- Box Tilters

- Polymethylpentene

- UHMW PE

- Polycarbonate

- Polyester (Thermoplastic)--PCTG Type

- Polyestercarbonate

- Nylon--Type 6/66 Copolymer

- Acrylic Copolymers

- Resin Clean-up Solutions

- Polyetherimide

- Syndiotactic Polystyrene (SPS)

- Polyarylsulfone

- PVC--Plastisols, Organosols

- Nylon--Type 11

- Polybutylene

- Polyetheretheketone (PEEK), Polyetherketone (PEK) and Other Polyketones

- PPE/PS Alloys

- Unscramblers, Orienting Devices

- LDPE

- PVC--Suspension or Mass General-purpose Resins

- Hopper Loaders

- Nylon--Amorphous

- Nylon--Type 46

- Thermoplastic Elastomers--Vinyl Type

- Polyphenylsulfone

- Lifting Devices

- Metering, Proportioning Equipment

- Acetal

- AES Terpolymer

- PVC--Copolymer Resins

- Parts/Runner Separators

- Dryers for Resins

- Acrylonitrile Copolymers

- Polyester (Thermoplastic)--PET Type

- Adhesion-Modified LLDPE

- Bag and Drum Dumpers

- Polyamide-imide

- Ethylene Copolymers and Alloys - Other

- ULDPE/VLDPE

- HDPE

- EPS Bead (including Copolymers)

- Expandable Polyolefin Bead

- Acrylic/Polycarbonate Alloy

- Semi-bulk Containers

- Polyimide (Thermoplastic)

- Feeders

- Polyester (Thermoplastic)--PCTA Type

- Fluoropolymers

- PVDC--Extrusion & Molding Grades

- ABS/pvc Alloy

- Thermoplastic Elastomers--Styrenic Type

- Nylon--Type 12

- Thermoplastic Urethane (Non-Elastomeric)

- Nylon--Type 66

- Thermoplastic Elastomers--Polyester Type

- Polypropylene (including Copolymers)

- Polylactide (PLA) Polymers

- ABS

- MDPE

- Weigh Scales

- Phenoxy

- Cellulose Acetate

- Butadiene Styrene Copolymers (not Including Elastomers)

- Nylons - Other

- Thermoplastic Elastomers--Polyether Block Amide (PEBA) Type