Metaspectral to Advance Vision Technology for Recycling

Company received further funding from British Columbia’s CleanBC Plastics Action Fund

Metaspectral, a software company advancing computer vision using deep learning and hyperspectral imagery, has secured $419,000 from the CleanBC Plastics Action Fund, established in 2022 by British Columbia’s Ministry of Environment and Climate Change Strategy, building on the previous $300,000 that the company received from the initial launch of the Fund in 2021.The aim is to further advance Metaspectral’s technology for recycling facilities that sort previously indistinguishable materials at the polymer level in real-time using computer vision and integrated robotics. This means that large quantities of plastic can be sorted and recycled more efficiently and accurately. It is already being used by the largest recycling company in Canada and has also attracted significant international interest.

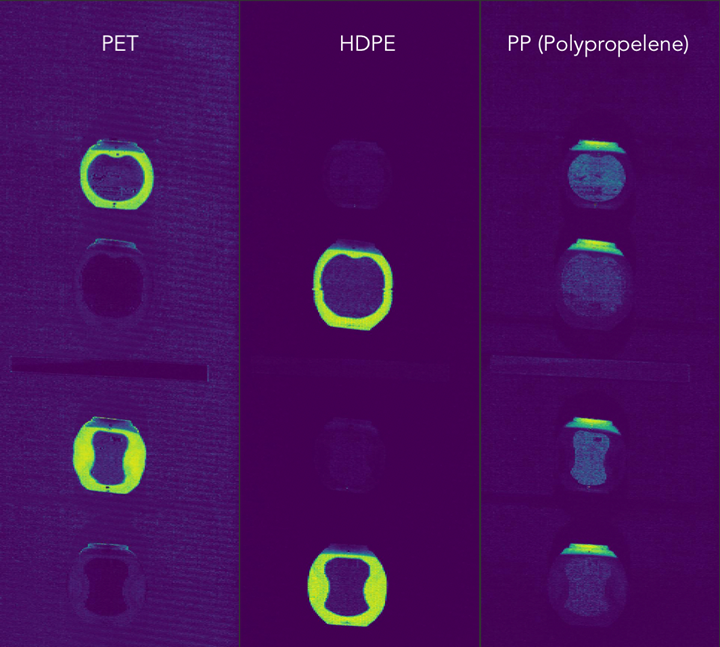

Said Migel Tissera, Metaspectral’s CTO and co-founder, “Our technology uses deep learning to analyze hyperspectral imagery from specialized cameras placed over a conveyor belt carrying recyclables; the images captured contain information from across the electromagnetic spectrum, making it possible for our algorithms to identify materials immediately and sort them accordingly.” said Migel Tissera, CTO and co-founder of Metaspectral.

Metaspectral's vision system for the recycling industry is designed to be installed on top of any conveyor belt. It detects all types of polymers, regardless of its condition (wet, dirty, perforated, etc.). Whether material is transparent, black, or mixed polymer, Metaspectral's Fusion platform detects and distinguishes the various types for accurate sorting at the molecular level. The technology uses “device agnostic” edge devices running compression algorithms that can be connected to any hyperspectral camera and turn its data output into a manageable flow. Metaspectral’s Fusion AI (artificial intelligence) platform can be used to interface with familiar user software, drive robotics, or feed artificial intelligence and deep learning systems. Metaspectral's vision system is customizable according to the task at hand, providing the capability to gain visibility in the NIR (900 – 1700 nm), SWIR (1000 – 2500 nm) or MWIR (2700 – 5300 nm) ranges of the electromagnetic spectrum.

This financing will support the continued development of the technology, with an emphasis on differentiating homopolymer HDPE, often found in milk containers, from copolymer HDPE, typically found in containers used to store automotive oil and detergents. In 2022, milk containers were added to British Columbia’s deposit-refund system, which adds up to 40 million additional containers to the province’s recycling system annually. The Government of Canada will require plastic packaging in Canada to contain at least 50% recycled content by 2030.

Related Content

-

OMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

-

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

-

Plastics Technology’s Most-Viewed Articles from 2022

Tips, new technologies, resin pricing, best practices and more piqued reader interest at Plastics Technology in 2022.