Arburg Grabs Spotlight at K 2013

WEB EXCLUSIVE: At K 2013, injection machine builder introduces the Freeformer, a novel machine for additive manufacturing.. But there was plenty to see in hot runners, LSR processing, and lightweighting as well.

One of the most dramatic announcements for injection molders at the show was not actually about injection molding. Arburg (U.S. office in Newington, Conn.) branched out in a new direction with its Freeformer additive manufacturing system, an inkjet-type 3D printer that builds up parts droplet by droplet in thin layers. Arburg is aiming this new machine squarely at its injection molding audience, offering them a new means to keep up with trends toward smaller batches and individualized products. The Freeformer is not so much for prototyping—which Arburg called “a thing of the past”—but to give molders new possibilities to make complex part geometries that cannot be injection molded and to allow them to produce economically in lots as small as one piece.

One striking innovation is that the Freeformer uses standard plastic pellets—almost any thermoplastic is said to be suitable, so long as it does not contain much filler or glass fiber, since the system uses a 0.2 mm orifice to dispense 0.3 mm droplets of melt. This not only allows processors to make fully functional parts from the wide range of commercial resins, but reduces material cost by up to a factor of 100, Arburg claims, by eliminating the need for special powder or filament raw materials.

The Freeformer uses a stationary vertical screw plasticator to melt the resin, which is dispensed under pressure through a stationary head at 100 droplets/sec using a piezoelectric system. The part is built up on a table that moves in three axes (standard) or five axes (optional). The latter has the advantage of allowing production of severe undercuts without support structures, saving material and secondary finishing operations. Maximum part size is 130 x 130 mm x 250 mm high. Build time for such a part is typically around 1 hr. Parts produced this way have no built-in stresses and reportedly achieve strengths about 70-80% of standard injection molded parts.

The Freeformer can use two melting and dispensing systems to make two-color or two-material (even hard/soft) parts. Colored materials can be used. Production is said to be free of dust or emissions, so that it can be used in any environment, even offices or clean medical production areas.

Like other additive manufacturing systems, the Freeformer takes CAD files in STL format and slices them into layers. A gesture-controlled multitouch screen reportedly makes it easy to use with no special programming or extensive training. “Just plug it in and start manufacturing,” Arburg says. The system is also very compact and fits through a standard doorway.

Price had not been set at show time, though it reportedly will be in the range of a high-end injection machine. The machine will be available next year.

Brand-new technologies are coming to injection molding itself. One is room-temperature UV curing of liquid silicone rubber (LSR) pioneered by Momentive Performance Materials, Waterford, N.Y. Benefits include faster cycles, especially with thick-wall parts, and ability to overmold LSR onto lower-cost thermoplastics such as PP rather than just higher-temperature engineering grades that can withstand LSR heat-cure temperatures. One of the questions about this technology has been how to expose the uncured silicone to UV light in the mold cavity.

At K 2013, Elmet of Austria (U.S. office in Lansing, Mich.) showed a novel solution at Momentive’s booth. Using an Engel e-mac electric press, Elmet supplied the LSR dosing system and mold (with the LSR mixhead mounted directly on the tool) for producing a PP soap dish with a non-slip silicone base. The hard PP dish was molded first and then transferred by a robot to a second cavity in the tool where it was overmolded on one side with LSR. The novelty was that in this second cavity, a clear plastic tool insert is clamped against one side of the PP part. Behind the clear insert was a UV lamp. Thus, the UV light was shone through the PP part to cure the silicone on the other side.

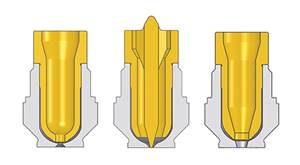

There was also lots of news in hot runners for thermoplastics at the show. Among the novelties was the use of conformal cooling in hot sprue bushings by Thermoplay of Italy. Made by laser sintering of powdered metal, the conformal-cooled bushings reportedly offer cycle-time reductions of up to 40% and improved dimensional control of molded parts with less shrinkage, warpage, and flow lines.

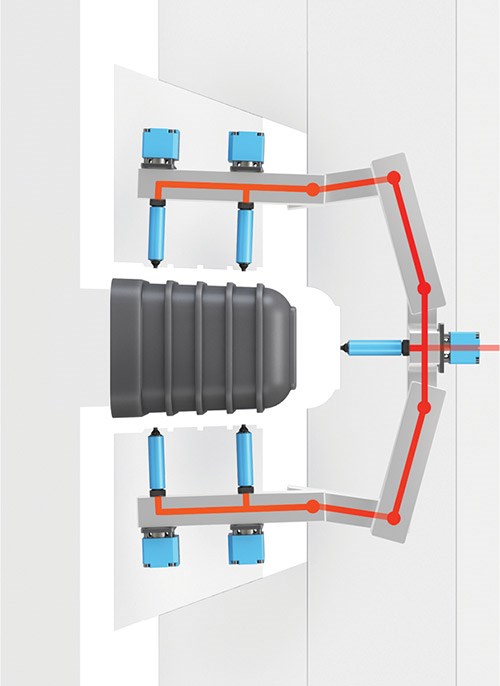

Also unusual is the new Rheo-Pro Slide Manifold from Mold Hotrunner Solutions (MHS), Georgetown, Ont. It has hinged melt-transfer joints that allow linked manifolds to move freely in order to distribute plastic anywhere inside the mold—even directly inside moving slides and lifters. The technology enables a continuous melt path across moving mold elements that are necessary for demolding complex parts with exterior undercut side features like ribbing. This type of flexible manifold can be useful for stack molds, tandem molds, and rotary and cube molds, MHS says.

Lightweighting is a major driver in automotive plastics applications, and a collaboration between 3M and Trexel has resulted in a new way to accomplish larger weight savings while retaining acceptable mechanical properties. This development teams up the newest hollow glass microsphere from 3M, St. Paul, Minn. with the MuCell microcellular foaming process from Trexel, Wilmington, Mass. Trials with glass-filled nylon and PP auto parts using MuCell direct gas injection and 8-10% by weight of 3M’s iM16K Glass Bubbles (introduced this past February) produced 15-20% density reduction—more than could be achieved with either means alone—while retaining comparable mechanical properties and equal or slightly (5-10%) lower cost. Improved properties might be obtained with surface-treated microspheres, which were not tested.

Side benefits are said to include improved dimensional stability and faster cycles from better flow and reduced stresses. Cross-sections of the parts show that the foam cells and microspheres are about the same size. There are no microspheres in the surface skin, which is slightly smoother than a standard MuCell part, though not Class A.

Related Content

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

(2).jpg;maxWidth=300;quality=90)