Automation & Waste Reduction: A Medical Molder's Efficiency

Vision Technical Molding in Manchester, Conn., doesn’t believe in standing still.

Vision Technical Molding in Manchester, Conn., doesn’t believe in standing still. This custom molder of tight-tolerance diagnostic devices, drug delivery systems, implantables, and other medical devices, achieved double-digit growth in each year from 2006 through 2009—never mind the recession—and has generated 25% growth in new sales this year. Last November, the molder (visionmolding.com) expanded its 54,000 ft² in two neighboring plants to 81,000 ft², splitting that extra floorspace between its molding operation and a sister moldmaking company, Advance

Mold & Manufacturing, Inc. (advancemold.com).

Accomplishing this takes a “vision,” as Zach Brodeur, business development coordinator, is quick to point out. It takes a willingness to shed old beliefs and apply resources in new ways to every phase of its process in order to improve production efficiencies and increase capacity.

Established in 1996, Vision focuses on minimizing tasks that add no value to the process, reducing redundancies, and optimizing use of advanced technology, from tool design to automation, to boost efficiency. Minimizing waste, be it material, labor, or machine time, is an imperative shared by all the firm’s employees. “We do not have the opportunity to reuse or recycle materials, and scrap is a big metric here. Every dollar of scrap and waste saved is a dollar that can go into development,” says Steven Arnold, president.

All this has paid off in measurable terms. Vision operates 28 injection presses from 28 to 330 tons on a 24/7 basis, but Brodeur says the cumulative effect of efficiency improvements over the past couple of years has given the firm the equivalent output capacity of four additional machines and three additional shifts a week.

EXPANDING CAPABILITIES

The expanded site houses all of its production presses in a new 10,000-ft² Class 8 clean room. Across the street, and in a separate dedicated clean room, are secondary operations such as pad printing, labeling, ultrasonic welding, heat staking, vacuum sealing, and custom packaging.

The clean room features separate staging areas for tools, people, and machinery coming into or leaving the clean environment. The means by which molds and equipment enter the clean room are a departure from the norm for most medical molders, according to Brodeur, but they help keep the particulate level, temperature, and humidity within the clean room as stable as possible. “In the building construction we integrated unique pass-throughs to maximize efficient transport of goods as well as communication between employees,” he adds.

Vision thoroughly cleans everything that enters the room, even the forklifts and other machinery that bring products into the clean room. Cardboard, wood, and certain porous materials are not allowed into the pressurized, climate-controlled room. Employees wear closed-toe shoes, hair nets, beard guards, gowns, and no jewelry or makeup.

There is room for about six additional presses within the existing clean-room space, and another 5000 ft² of unfinished space sufficient to house 15 presses is “clean-room-ready” with cranes, HVAC, and utilities already installed.

SYNERGY WITH MOLDMAKING

Vision benefits from its close rapport with its toolmaking sister company. Vision gets 70% of its tooling from Advance. In fact, the moldmaker was founded first (in 1959), and ventured into molding when customers requested capabilities to sample the tools and later to mold initial runs of up to 10,000 parts.

Vision accounts for about 10% of Advance’s business, yet the close collaboration in design and manufacturing has yielded unique designs that allow Vision to achieve tolerances down to 0.0001 in. in steel and 0.0005 in. in plastic. Advance also uses conformal cooling to improve productivity of tools intended to run sub-10-sec cycles.

Together, Vision and Advance relieve customers of the burden of managing tool builds, which shortens lead times. Vision president Steve Arnold and Advance president Doug Schneider each holds a v.p. or business-development post with the other company, to further deepen the relationship between toolmaker and molder. And both companies run tests in Advance’s mold-test center on processes such as insert molding and two-shot LSR/thermoplastic overmolding. One of Vision’s presses “floats” between its production floor and the mold test lab.

Another advantage of having your moldmaker nearby, says Brodeur, is that “we don’t have to ship molds around and risk breaking something—we just roll them down the hall. And if we need a replacement part or modification, it’s right next door.”

HUNTING FOR EFFICIENCIES

Several aspects of Vision’s approach to manufacturing are said to make it more efficient. Rigorous mold and machine maintenance procedures are designed to minimize unforeseen downtime and extend the useful life of tools and equipment. Other special procedures are used to meet strict customer requirements for purity and to prevent cross-contamination.

Rather than simple machine purging after a job is completed, Vision implements a complete teardown and overhaul of the screw, barrel, check ring, and nozzle. Maintenance staff cleans each machine component first by heating it to the glass-transition temperature of the polymer, then mechanically removing any degraded resin with a wire brush. These maintenance procedures take place outside the clean room.

Automation in materials and parts handling also play a large role in factory-floor efficiency. Most of Vision’s larger presses (110-ton and up) have three-axis robots to provide positive part removal from the tool and present parts for assembly and packing. Sprue pickers are used with the smaller presses, located in a second manufacturing bay in the clean room.

For one job with a 96-cavity tool running less than 10-sec cycles, parts are collected shot by shot and bagged automatically. The shot-collection mechanism is exposed to UV light to kill germs and “reduce bio-burden,” as Vision puts it.

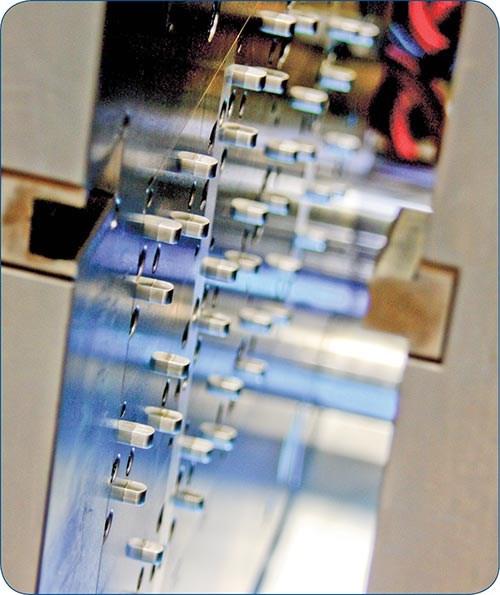

Another key source of efficiency is a centralized material handling and drying system from Wittmann Group. The system, mounted on a mezzanine level away from the molding floor, has a bank of vacuum loaders that can deliver materials to a bank of dryers of various sizes and then to the presses. Having a full range of dryer sizes and a central system rather than dryers tied to a specific machine allows for more flexible and efficient use of drying capacity, says Arnold. The all-stainless system is operated from a central control panel. When a resin is selected for a job, the system automatically prepares the resin according to a stored recipe of drying time and temperature. Off-line material testing occurs every 24 hr to confirm accurate drying.

At each press, a Wittmann material hopper calls for resin in a “Just-in-Time” fashion. After each loading cycle, a dry air blast is sent through the conveying tubes to ensure that no pellets are left behind.

Vision has standardized its press line mostly on Milacron Fanuc all-electric Roboshots. Standardizing presses brings portability for process profiles and tooling from machine to machine.

Scientific Molding principles are the foundation of Vision’s approach to processing. Cavity-pressure monitoring with RJG Inc.systems is used for the most life-critical applications. The company has two RJG-certified master molders. Vision also uses Fanuc’s Mold24i plantwide controller to monitor the status of every press in the room.

These tools help to streamline the manufacturing process and prevent technicians from making mistakes that can lead to wasted time and material, says Brodeur. “Management can see what each press is doing all times of day or night, whether they are on-site or not. This allows us to minimize downtime and make decisions to run or not to run across three shifts.”

Vision is also looking to tackle new capabilities. Under evaluation is one potential job in which two parts previously molded separately then assembled off-line in a third step would now both be molded on a single press, using in-mold assembly in a rotating “cube” mold. “This could cut finished product cost for the customer by up to 50%,” Brodeur says.

Vision is also using automation for in-process part inspection. In a corner of the clean room sits a custom-built system capable of inspecting parts from each cavity of a 96-cavity tool for dimensional accuracy and color. It uses a small vision-guided, six-axis Adept robot to present parts to a Keyence laser micrometer, Cognex vision system, and Mettler Toledo laboratory scale. After reading the cavity ID using optical character recognition, the inspection data is output to a central SPC system for monitoring and analysis. This system trims inspection time for all 96 parts by 64%, says Brodeur.

“We compete mainly on quality,” Brodeur states. “We’ll never be the cheapest molder out there. We strive to exceed customers’ quality expectations while delivering minimal lead times and costs.”

Related Content

Conair Names New Execs in Sales, Systems, Product Management and Extrusion

Moves aimed at strengthening customer focus, market awareness, and technical expertise in key areas of our business.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

Read MoreResin-Selection Station Conveys Material on Demand

NPE2024: Powerful, space- and labor-saving station makes the connections and conveys material automatically on command.

Read MoreWisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More