Carbon Nanotubes Improve In Properties, Purity and Price

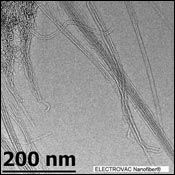

ew suppliers and manufacturing technologies continue to emerge in the burgeoning field of carbon nanofibers (CNFs) and single-walled carbon nanotubes (SWCNTs). Recent news includes North American availability of CNFs from Austria’s Electrovac Group.

ew suppliers and manufacturing technologies continue to emerge in the burgeoning field of carbon nanofibers (CNFs) and single-walled carbon nanotubes (SWCNTs). Recent news includes North American availability of CNFs from Austria’s Electrovac Group. Also, a low-cost process for making SWCNTs has been developed by the NASA Goddard Space Flight Center and has been licensed to three start-up companies that aim to make low-cost hollow SWCNTs available within a year.

Owing to the much higher cost of SWCNTs, most of the commercial activity in carbon nano-particles has involved multi-walled carbon nanotubes (MWCNTs), which are single tubes with five to 15 layers; and the closely related CNFs. As we reported in July (see Learn More), MWCNTs can be bought for about $150/lb and CNFs for $100 to $150/lb, although even lower prices are on the horizon. SWCNTs offer better properties, but prices so far have been 50 to 100 times higher—about $300 to $500/gram on the low end. But the new NASA technology is about to change that, bringing estimated initial price reductions of about 50%.

New nanofiber process

CNFs have excellent electrical and mechanical properties, such as high stiffness and tensile strength. They conduct electricity better than copper and in some cases act like a semiconductor. Their thermal conductivity is comparable to metals and diamond.

According to Electrovac nanotechnology product manager Robert Schwertner, “The drawbacks in CNF production so far have been the high cost and a discontinuous batch process. And catalyst residues have led to inconsistent quality.” After making CNFs in a batch-process pilot plant since 2003, Electrovac recently started up a larger plant using an automated, continuous chemical vapor deposition process. It reportedly is more efficient and produces “cleaner” product. Electrovac’s total capacity now exceeds 22,000 lb/yr. Its CNFs are newly available here through Curamik Electronics.

Electrovac has formed cooperative partnerships with major plastics resin producers, compounders, and processors. “Our objective is to create a better understanding of where and how to use this carbon nanofiber as an additive,” says Schwertner. Electrovac offers CNF masterbatches in PE, PP, EVA, SAN, ABS, nylon 6 and 12, PC, TPU, TPE, acetal, and PET.

Leading areas of interest are industrial applications and machine parts. For instance, industrial printers use plastic paper feeders filled with carbon black to prevent static charge build-up. The drawbacks have been high wear and abrasion as well as problems related to bowing of the feeders. Says Schwertner, “By applying Electrovac nanofiber compounds, abrasion can be eliminated and deflection can be reduced to an acceptable minimum.”

Antistatic plastics are also used in electronic microchip production, but carbon particle contamination has been a major problem. “By using CNF-filled plastics for wafer-handling components, a significant reduction in particle contamination can be achieved,” Schwertner states.

Other targets include housings of computers and measurement instruments, where both thermal management and electrostatic discharge are highly important. Electrovac is working in partnerships geared to developing a new generation of laptop housings with improved mechanical and heat-dissipation properties.

Electrovac is also aiming its CNF compounds at automotive applications that use electrostatic painting, such as PPO/nylon fenders that would not need a conductive primer, thus cutting cost significantly. Electrovac is also developing CNF-filled compounds for antistatic fuel containers.

Lower-cost SWNTs coming

NASA’s SWCNT production process has been licensed to Nanotailor, Idaho Space Materials, and E-City Nano Technology. Potential markets are said to be vast—in medical and optical parts, construction, and other industrial uses—for this simpler, safer, and much less costly manufacturing process, according to Dr. Jeanette Benavides, a recently retired NASA Goddard researcher and developer of the technology.

The NASA process can produce bundles of SWCNT’s without using a metal catalyst, dramatically reducing production costs while generating higher yields with better quality. Says Nanotailor chairman and CEO Bryan Scott, “All other SWCNTs are based on metal catalysts. This makes them very costly, as you must remove the metal from the SWCNTs. So we save on production time and cost. What is really unique is that our SWCNTs can be incorporated with only minor modification directly into the plastic.”

This technology produces nanotubes of greater than 95% purity, which reduces the company’s separation costs, explains Reginald Parker, Nanotailor’s chief technology officer. These tubes have lengths up to 15 microns and diameters of about 1 nm, yielding aspect ratios up to 15,000:1.

According to Parker, these SWCNTs are inherently functionalized, which allows them to be used in a wider array of plastics, whereas conventional SWCNTs must be functionalized with an acid treatment. “These SWCNTs have inherent and tuneable miscibility in many plastics. Nanotailor’s initial work confirms that these nanotubes can be incorporated easily into an array of thermoplastics and thermosets.

Most trials have focused on conductive polymers for electronics. “We’ve been looking at polymers that have alternating double-bond/single-bond structures, where we find that use of only about 0.5% of these SWCNTs provides tremendous conductivity,” Scott says. He says his products yield electrical and thermal conductivity with much lower loadings than MWCNTs, which helps balance the cost difference.

Other potential uses include improving mechanical properties in surgical joint replacement or dental prostheses, as well as structural beams and thermoformed interior and exterior door panels and floor liners for trucks.

Nanotailor plans a commercial launch of SWCNTs in the first quarter of 2008 at prices half of those for such products before now. This will make it attractive for processors to explore their higher conductivity, stiffness, and strength than other carbon nanotubes.

Related Content

10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More