Injection Overmolding Widens Horizons For Composites Processor

A specialist in thermoset composites since the 1960s, CCP Gransden is a relative newcomer to thermoplastic composites and to injection molding. Its exploration of organosheet overmolding has opened up new potential.

CCP Gransden knows composites—since the 1960s it has established itself in thermoset RTM, vacuum infusion, and filament winding. In 2012, the company saw new opportunities for growth in thermoplastic composites. Today, it offers press forming and compression molding of TP composites, along with its newest technology—injection overmolding of TP prepregs.

Based in Ballygowan, Northern Ireland, CCP Gransden produces custom composite parts for aerospace, automotive, security and defense. Faster production, simplified processes, and recyclability are reasons why the firm is placing growing emphasis on TP composite technologies. The principal driver is the automotive industry, but aircraft manufacturers are also increasingly requesting thermoplastic solutions from CCP Gransden. Explains Peter Quigley, engineering manager, “We adapt processes developed for the automotive industry to aircraft manufacturing. The exciting thing is that we often bring back the optimized processes into the automotive industry, thus increasing efficiency and performance there.”

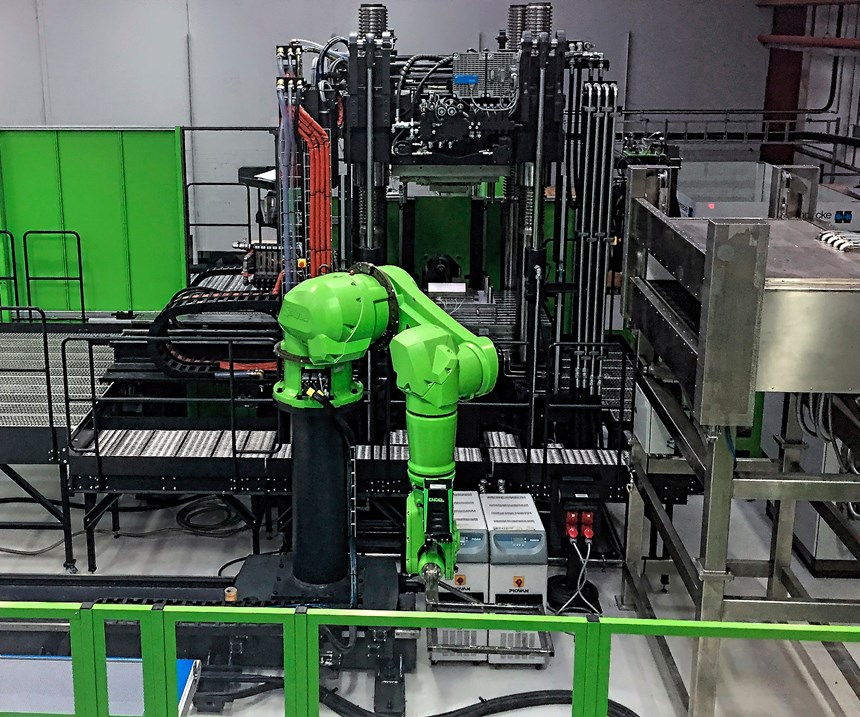

To explore the TP composite field, in 2016 CCP Gransden installed an Engel v-duo injection machine—one of the first of these units in the U.K. This is a servohydraulic machine with a vertical, two-platen clamp. It was developed specifically for composites applications. Its low operating height simplifies manual tasks and suits the machine well to R&D uses. The clamp can be equipped with a sliding table, facilitating a variety of automation concepts.

This machine has given CCP Gransden an entry into the promising technology of what the firm calls single-stage overmolding—which Engel calls the organomelt process. Long-fiber-reinforced blanks or organosheets—prepregs with a thermoplastic matrix--are heated in an infrared oven (incorporating special features of the molder’s own design) and then placed in the mold, where they are formed and directly overmolded with thermoplastic to create ribs, attachment points, and other functional elements. “Combining thermal forming and functionalization in the same mold and in a single stage make this process extremely efficient,” says Steve Taylor, sales engineer for Engel in the U.K. “Many competitors are still separating thermoforming of the organosheets and overmolding into two independent work stages, requiring two molds and often two machines. The integrated and fully automated process in a single machine is not only faster and more cost-effective, but also results in better part quality.”

Explains Quigley, “At the point of injection molding, the preform is in a molten state. This ‘melt-melt’ interface allows polymer chains and fibers to cross the bond line, resulting in an extremely strong and stable bond between the organosheet preform and the overmolded functional elements.” He adds: “We are already achieving cycle times today of under two minutes. This is the key to realizing the costs per unit demanded by the automotive industry.”

Injection molding was brand-new to CCP Gransden, so its team relied on Engel experts in the U.K. and its Center for Lightweight Composite Technologies in Austria. CCP Gransden learned the process on its new 1100-metric-ton v-duo press, equipped with a six-axis articulated robot from Stäubli. The entire process, including the IR oven, is centrally controlled by the v-duo’s C300 control panel. “This is a huge advantage for us,” says Quigley. “Integration of all control simplifies operation and provides a better overview, especially when the processes are complex.

CCP Gransden started out using the machine for R&D sample parts with the new machine in both overmolding and HP-RTM, but customers pushed to use it for commercial overmolding production. “We are launching series production with the first customers,” states Jim Erskine, owner and managing director. “We can produce up to 100,000 composite parts per year from one tool.”

In addition to the PEEK and PPS resins established in aircraft construction, CCP Gransden has applied the v-duo machine to processing nylons preferred in automotive and has experimented with PPA. So far, the company has worked primarily with organosheets, but is putting increasing focus on unidirectional reinforced TP tapes, which allow even more precise control of part properties.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

(1).jpg;maxWidth=970;quality=90)