Larger, All-Purpose, All-Electric Machines Debut from Milacron

As reported in our Keeping Up section last month, Milacron LLC invited Plastics Technology to its Batavia, Ohio, headquarters for an exclusive preview of its new Elektron line of all-electric injection presses ahead of their official debut at Milacron’s open house Apr. 24-25.

As reported in our Keeping Up section last month, Milacron LLC invited Plastics Technology to its Batavia, Ohio, headquarters for an exclusive preview of its new Elektron line of all-electric injection presses ahead of their official debut at Milacron’s open house Apr. 24-25 (see Starting Up section this month). Here are more details on the new series.

BIGGER ALL-PURPOSE MACHINES

As explained by electric platform product manager Eric Thompson, the Elektron line was developed to meet demand for larger, multipurpose all-electric machines for bigger automotive parts requiring higher precision, as well as industrial applications like small trash cans and bins, or custom molders with a wide range of applications.

Milacron already has the PowerPAK series of all-electrics from 440 to 1125 tons, but they are specialized for high-speed/highinjection-rate applications, such as packaging. The new Elektron line complements the Roboshot series of all-electric models. Roboshot presses extend up to 330 tons standard, while the first two Elektron models (both to be running at the open house) are of 400 and 500 tons, with 600- and 725-tonners coming later this year.

The Elektron name is new to the U.S., but Milacron offers a full lineup of Elektron models from 55 to 500 tons in Europe and Asia, where Milacron does not market Fanuc’s Roboshot series. Besides a new U.S. name, the Elektron models also look different. “They wear the new ‘dress,’ similar to our Ferromatik Milacron F series, that will become the uniform style for all Milacron machines,” says Michael Prachar, v.p. of marketing for global plastics machinery.

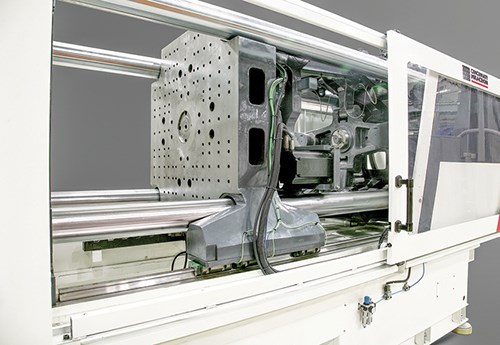

The larger Elektron presses have a newly designed five-point, 10-pin toggle clamp that rides on linear bearings. As Thompson explains, “This provides a greaseless part-drop area, which is good for high-cavitation jobs where some parts might scatter and touch the tiebars. If there were the usual grease on the tiebars, some parts might become contaminated—but not with these machines.” He also points out the large, open part-drop area on the new models.

Elektron models also have a newly designed injection unit with single or twin ballscrews, depending on size. The new models are offered with a choice of three injector frames, each with three available barrel sizes. The Elektron 400 thus comes with shot capacities of 12.8 to 54 oz and the Elektron 500 with 18.4 76.9 oz.

To help keep the machine clean, a diamond-pate purge shield attached to the fixed platen is standard.

Like PowerPAK models, Elektron units have water-cooled motors with self-contained, closed-loop cooling units. They also offer energy regeneration from braking, recapturing perhaps 8-9% of energy consumption and recycling it to other machine functions.

Brand-new on the Elektron machines (and also being extended to MTs servo-hydraulic toggles) is the Endura Touch controller. It has a 15-in. touchscreen vs. the 10.5-in., non-touch display on the Endura II. “Endura Touch has the look and feel of our high-end Mosaic control with the same functionality as the Endural II,” Thompson says. Standard features include software for core pulls, air blast, robot interface, pneumatic valve interface, and process monitor. “No page is more than two clicks away,” Thompson adds.

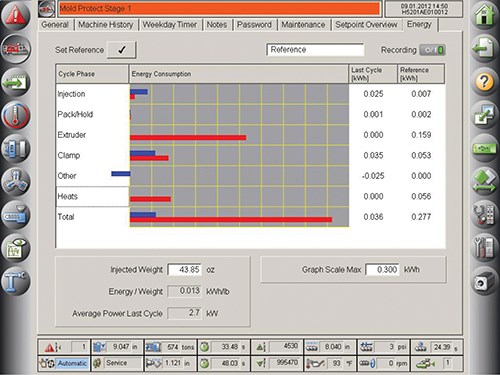

The Endura Touch control also incorporates a new energy-monitor screen as standard, which displays net energy usage for the overall cycle and separately for injection, pack/hold, plastication, clamping, and heating. As shown in the photo on p. 13, the display offers easy visual comparison of blue bars for a stored reference cycle and red bars for the current cycle. Users can set upper and lower control limits for SPC monitoring of energy usage.

Further, if the user enters the part weight, the control shows the specific energy consumption, or energy use per weight of plastic—the most relevant measure of energy usage, according to Ronald Hertzer, director of global product development, who will be speaking about energy management at the open house. He notes that the energy monitor can be used to optimize cycles for a balance of productivity and energy efficiency. “We have also found that monitoring energy consumption can help molders detect changes in material viscosity, moisture content, or melt temperature.”

Related Content

Custom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreAll-Electric Press Gets U.S. Debut

NPE2024: For the first time, Arburg is making a global premier of a machine outside Germany with the new Allrounder 720 E Golden Electric among its 13 exhibits — seven in its own booth — in Orlando.

Read MoreArburg Debuts New Machine Outside of Germany for First Time

NPE2024: Arburg says the Allrounder 720 E injection molding machine premiere highlights the importance of the show and market.

Read MoreCompact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreRead Next

Exclusive: Milacron Launches New All-Electric Press Series

At press time last month, Milacron LLC, Batavia, Ohio, gave Plastics Technology an advance look at a line of all-electric machines being launched globally this month.

Read MoreExclusive: Milacron Launches New All-Electric Press Series

At press time last month, Milacron LLC, Batavia, Ohio, gave Plastics Technology an advance look at a line of all-electric machines being launched globally this month.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More