Milacron Is ‘Going Big’ at NPE2018

Milacron is emphasizing large-tonnage injection presses, enhanced customer service to maximize their uptime, and speed—both speedy delivery of parts and suppies, and products that speed up production for their customers.

There is plenty to catch the eye—or stop you in your tracks—at the Milacron booth this week. “We wanted to go big this year at the show,” says Mike Sansoucy, v.p. of injection molding sales for the Americas. How big? For one thing, there’s a 2250-ton model of the new Cincinnati line of two-platen presses—the largest tonnage injection machine ever run at an NPE, Milacron states.

It will be molding an ATV side/by-side dashboard. Not big enough for you? Then you’re welcome to gape at the platen for a 6600-ton “beast” being built for 20/20 Custom Molded Plastics in Holiday City, Ohio. (If they brought the whole machine, there’d be little room for anything else.) There’s also the biggest all-electric Roboshot press ever offered in the Americas—a 500-tonner (450 metric tons).

Milacron is also “going big” in the scope of its exhibit: from injection molding (four different machine lines represented) blow molding, and extrusion to hot runners, tooling components, and aftermarket supplies—every one of these business areas showing new and enhanced products and services. More than enough to fill 18,700 ft2 in Booth W2703.

There’s something else to catch the eye, too: Experience “augmented reality” with “smart glasses” that allow you—or a Milacron service technician—to “walk through” the innards of a machine or navigate the control system as if an expert technician were leaning over your shoulder.

To Michael Ellis, director of marketing and communications, the augmented-reality demo perfectly sums up two key themes of Milacron’s exhibit: “Service and Technology.” He explains, “We have had a new vision for the company in the last year—to lead transformation of the delivery of service in plastics equipment.”

Milacron’s definition of service, he adds, “is to help optimize uptime for our customers.” One thrust of that effort is enhancing connectivity of its machines, including remote monitoring and troubleshooting analysis, for which augmented reality is one tool. It’s all part of the Internet of Things or Industry 4.0 trend, which the company calls Milacron M-Powered.

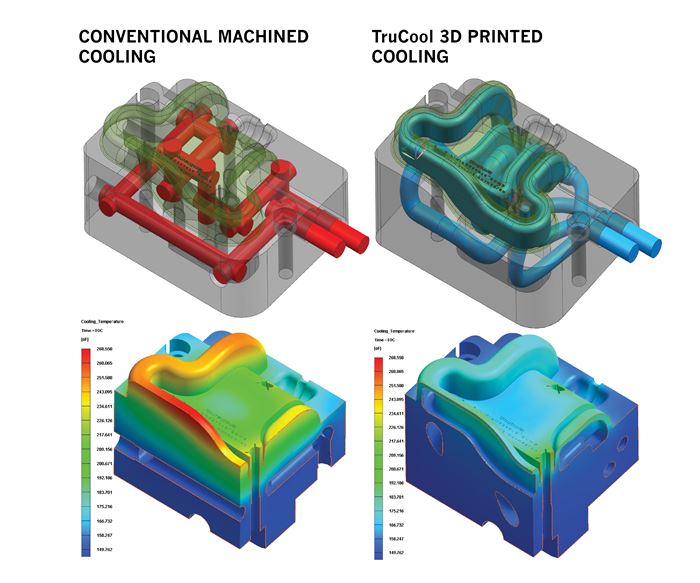

“We’ve also spent a lot of time on our aftermarket products,” Ellis notes. “We’ve increased stock levels in the U.S. to guarantee that spare parts are in stock and ready for same-day shipment, if needed. This is across many of our products and brands, including injection and Mold-Masters. We’re also adding head count to our service team—more feet on the ground. And at DME, we are focused on speed—getting products to customers faster, as well as offering them products that can speed their production, like our new TruCool products and services related to conformal mold cooling, and there’s our e-STORE, which is foundational for DME and has been enhanced with a number of new products unveiled at the show.”

Ellis and his colleague, Michael Crawford, corporate communications manager, can’t resist noting a couple of other attention-getters at their booth. First, Milacron will be serving pineapple segments from its Klear Cans in celebration of the first commercial application of this co-injected barrier container, based on Kortec hot-runner technology. And second, members of the Kortec co-injection team have encouraged molders to come visit and bring products, or ideas for products, that could possibly take advantage of multi-layer co-injection technology.

Related Content

Next-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

Read MoreArburg Marks Anniversary with New Generation of Machines

The Hehl family company, which grew into Arburg, marks its centennial this year with a new generation of energy and resource efficient hybrid injection molding machines.

Read MoreInjection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.

Read MoreAbsolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More