3D Printing Company Embraces Direct Digital Manufacturing

CloudDDM has launched its operations at the UPS Supply Chain Campus in Louisville, KY.

There is plenty of excitement surrounding the additive manufacturing (3D printing) space as the technology is reshaping the way products are designed and produced. However, Mitch Free, co-founder and CEO of the newly launched CloudDDM (Atlanta, GA, US), believes a new approach to additive manufacturing is required in order for the technology to reach its full potential.

“I realized there were two needs for high-quality, end-use parts in the market that were not being addressed by additive manufacturing service providers,” he told Plastics Technology. “The first is speed. Whether a customer needs a prototype or a 3D-printed jig or fixture— the faster they can receive it, they faster they can move their project along. As the old adage goes, ‘time is money’ for our customers and we are sensitive to that.”

The second need was scale, he said.

“There is a ‘no man’s land’ between prototyping and enough volume to justify building tools for molding,” he said. “CloudDDM has enough capacity to produce a lot of parts quickly to meet the demands of an OEM with a low volume or niche product.”

CloudDDM’s additive manufacturing facility is located on the UPS Supply Chain Campus in Louisville, KY. UPS has also taken a minority stake in CloudDDM through the UPS Strategic Enterprise Fund, a corporate venture capital fund.

"We are excited to have CloudDDM as a resident on our UPS Supply Chain Campus,” said Mark Wallace, UPS president of global logistics and distribution. "Locating at UPS Worldport allows CloudDDM to leverage our integrated network and end-of-runway location to get 3D-printed parts in the hands of their customers as quickly as possible. As this technology continues to become more mainstream, UPS has the ability to scale the shipping and logistics solutions to meet the additive manufacturing services provided by CloudDDM.”

As of launch, CloudDDM has completed Phase I of its installation on the UPS Supply Chain Campus and expansion is already underway. Additionally, plans are being made for additional operations to be established in Europe and Asia.

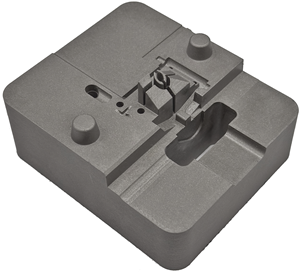

The facility features 100 3D printers running 24 hours, 7 days a week. Free said that the company is using purpose-built additive manufacturing machines that are not commercially available. The company can produce parts using several materials including ABS, polycarbonate, polycarbonate-ABS and Ultem 1010.

“Our systems are almost entirely automated, from the time a user uploads a digital model, through production, and on to packaging and shipment,” he said. “Direct digital manufacturing allows us to be incredibly efficient and produce parts, in large volumes, at prices competitive with traditional manufacturing methods.”

Due to the high level of automation in its facility, the number of employees they need is very low (just three employees). Free said there are times when no one is in the facility and the machines are still producing parts.

Stratos Aircraft, Flextronics and Devon Works are already customers of CloudDDM.

“Our customers require high quality parts with structural integrity as the consumer grade 3D printers would not be adequate for their needs,” Free said. “Further, our customers trust us to make sure their proprietary data and the details of their next generation product are secure.”

Free believes this is the beginning of the next industrial revolution.

“We are building the global elastic cloud for direct digital manufacturing,” he said. “The ability for supply chains to leverage globally distributed on-demand manufacturing is really big opportunity for OEMs that take advantage of it.”

Related Content

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreGetting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

.png;maxWidth=300;quality=90)