New Program Guarantees Performance of Auxiliary Equipment

Web-based and cloud-powered, Conair’s new SmartServices platform is key to its just-launched ‘Uptime Guaranteed’ initiative.

Long-running investments in the technology it designs and builds, as well as the people and infrastructure needed to support it, coupled with new Industry 4.0 tools, have put Conair, Cranberry Township, Pa., in a position where it feels it can stand unequivocally behind its equipment.

“What we think is natural is kind of a next step to this notion of ‘Uptime Guaranteed,’” explains Conair president Larry Doyle. “We make a promise to our customers assuring them that our equipment will rarely, if ever, be the reason or the cause of that unintentional production stoppage.” Conair unveiled its program last month at NPE2018.

“The industry has seen the evolution over the course of many years of people touting 24-hour service or parts in stock or all sorts of things to help support the customer,” Doyle says. “One of the things that we’ve done differently over the years is put in things like a performance guarantee, where we’re not just warrantying equipment but we’re guaranteeing the performance of the equipment.”

With Uptime Guaranteed, Doyle says Conair will be able to tell customers exactly how close to 100% uptime they can expect from their equipment, based on their process parameters and other factors. Using this data, the company can then guarantee the uptime percentage, whatever it may be. “If the equipment doesn’t meet those benchmarks,” Doyle says, “we will take ownership of the problem. We will fix or replace the equipment and work with our customer to make sure those uptime objectives are achieved. This is what we mean when we talk about Uptime Guaranteed.”

Doyle notes that Conair has long invested in and strengthened its service presence. The company’s Instant Access Hotline makes spare parts or service just a call away, 24/7. In addition, Conair’s service techs work from an inventory of more than 50,000 line items—over 1.5 million parts total. The company says it ships nearly 90% of parts orders within one business day and usually within six hours. If on-site assistance is needed, Conair’s team of field-service professionals has almost 40 techs.

CLOUD-POWERED, INDUSTRY 4.0 ENABLED

Tied directly to Conair’s new performance guarantee is a new cloud-based monitoring system called Conair SmartServices. Conair says SmartServices captures all of the data generated by the controls on virtually all Conair equipment and many auxiliaries sold by other companies. A small module installed inside the equipment’s control panel wirelessly transmits all that process information to a database in the cloud, where it is stored and analyzed by proprietary algorithms developed by Conair. Processors can access the information from their equipment using a web-based platform that allows them to organize data by cell, plant, product line, etc.; and companies with more than one location can track all their equipment globally or zero in on an individual site.

Doyle says the SmartServices offering will not only be sold on new equipment but can retrofitted to certain older equipment. “That will provide valuable insight into performance and monitoring of the equipment,” Doyle says. “It will be able to report back out diagnostics and help us with process optimization and understanding what types of data are really indicative as to how the machine is performing.”

At NPE2018, Conair had different functioning systems with live services and interactive displays to let attendees see the gathered data, as well as SmartServices dashboards, both on equipment running in Orlando but also equipment operating at customer sites and at the company’s own lab. “At the end of the day, customers want our equipment running,” Doyle says. “They don’t want unplanned downtime because unplanned downtime equals lost productivity, which equals lost profits.”

Doyle says SmartServices harnesses the data already gathered by its equipment into a format that its customers can readily exploit. “SmartServices is based on the fact that the controls of Conair equipment already gather a ton of data,” Doyle says. “Right now, it resides only in the control.” Going forward, after the addition of compact wireless machine adapters (WMAs), described by Doyle as being the size of two decks of cards stacked on top of one another, the control panel can then transmit data up to the cloud via the customer’s own network.

“SmartServices is a cloud-based, web-based platform that is extracting data from our machine’s control and then posting that data out to the cloud and doing analytics on it,” Doyle says. “It is then repurposing the data into a dashboard that our customers can remotely access and monitor.” Once the system is analyzing process data, it can alert, alarm, and message the processor, as well as predict potential failures.

NO-COST TRIAL AVAILABLE

The program is launching with a no-cost, six-month trial promotion, where processors can try out SmartServices in their own facility with their own equipment. Conair stresses that the program’s web-based design means customers will never need to make hardware or software upgrades to have the latest version of the platform; it will be automatically upgraded on the web by Conair.

Once the WMAs are installed and a connection is made, users can identify and configure their auxiliaries into the system, organizing them by equipment type, plant names, production lines, and physical locations. Once enabled, WMAs automatically collect data from each piece of auxiliary equipment and transmit it to the secure, cloud-based SmartServices database where it is processed and stored.

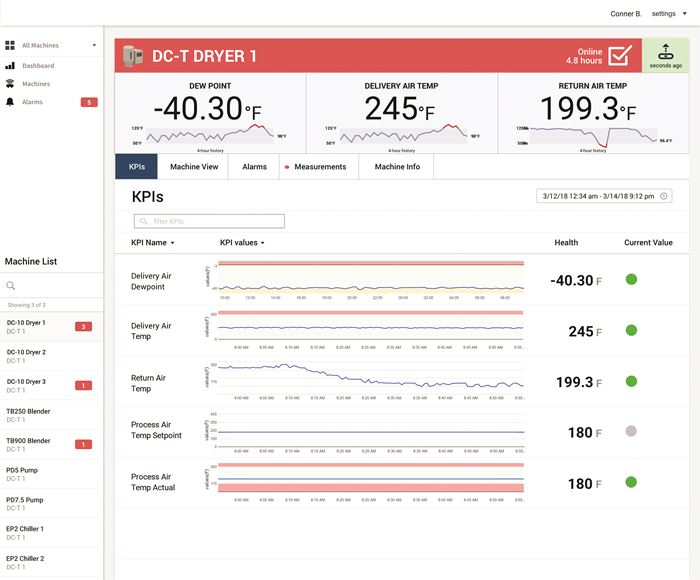

The SmartServices web portal then populates a dashboard with user data, creating a clickable list of user-specified equipment groups on one side and a large working screen on the other. Within the dashboard, users can dig into Key Performance Indicators (KPIs) for each piece of equipment.

At the end of the day, customers want our equipment running. They don’t want unplanned downtime because unplanned downtime equals lost productivity, which equals lost profits.

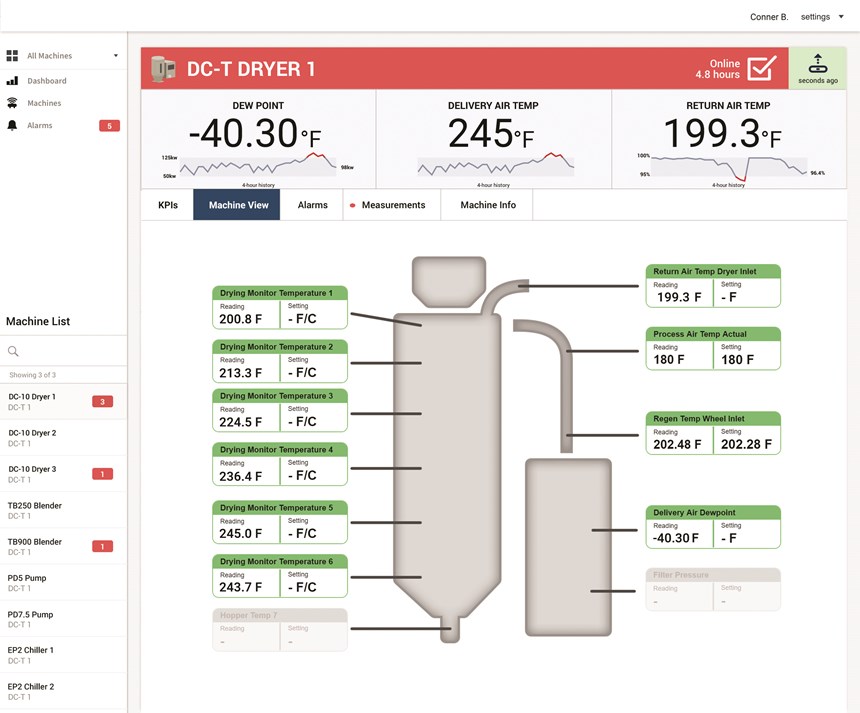

The KPI display shows real-time data, with three items highlighted by default. Additional KPIs are shown in the form of real-time line graphs, and each one is color coded—red, yellow, or green—so users can quickly scan current operating conditions and performance trends. The Machine View display shows a schematic of the equipment overlaid with readouts of setpoint versus actual readings. On a dryer, for example, hopper-inlet air temperature, temperature gradients within the hopper, outlet air temperature, dewpoint setting, and target moisture level would be shown.

The Alarms screen displays real-time alarm status and history. A special panel allows managers to create an alarm hierarchy, and generate messages specific to each alarm type, with direct alarms sent to specific individuals or groups, depending on their type. Going further, Conair parts and service staff could be integrated into an alarm notification, enabling them to respond proactively.

Going forward, SmartServices will collect, analyze and store performance data from thousands of auxiliaries connected worldwide, creating an auxiliary-equipment database that can be leveraged by both processor and Conair personnel.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreHonoring Excellence at NPE 2024: Plastics Hall of Fame

Yesterday, the Plastics Hall of Fame celebrated a legacy of innovation and vision for the plastics sector with 17 new members. Discover how these pioneers have helped shape the future of plastics.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More