Novel Molds & Machinery for Medical Molding

Injection Molding

The combined MD&M East and Plastec East shows in N.Y.C. in June presented intriguing developments for medical injection molders.

The combined MD&M East and Plastec East shows in N.Y.C. in June presented intriguing developments for medical injection molders. Among them were an unusual micro-molding machine design, as well as innovations in hot runners and tooling.

NOVEL MICRO-MOLDER

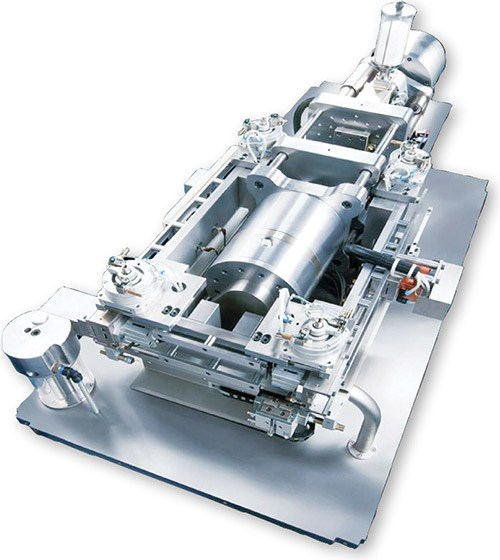

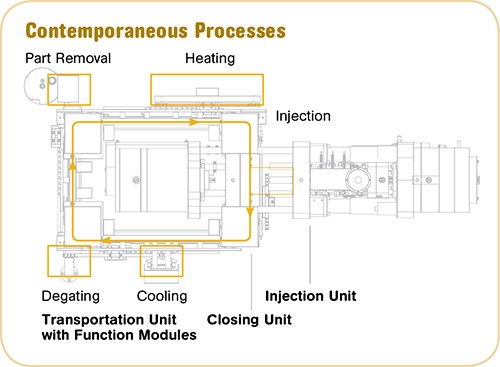

Otto Männer of Germany, best known for hot-runner systems and precision molds, has launched its first complete micro-molding cell. First shown at the K 2010 show in Düsseldorf last fall, the micro-män 50 is a 5-metric-ton, all-electric machine of unique design. Its distinctive feature is the “track-män” concept: This is a standardized, two-piece mold half with a mold insert and integrated ejector package. This movable hot half travels horizontally around the periphery of the machine on a mechanical track.

After injection, the mold opens and the mold half leaves the clamp and travels to a cooling station, where it is contact-cooled by water cooling in the machine base plate. Then it travels on to the degating station, followed by a station for part removal by suction, and then to a two-stage induction-heating station. This system thereby applies a Variotherm heat/cool process outside the clamp area, so there is no cycle-time penalty. Multiple injection units can be installed in one cell for overmolding.

The clamp is moved directly by an electric torque motor and is said to be virtually wear- and maintenance-free. It has an opening stroke of 110 mm and max. daylight of 200 mm. Mold area is 200 x 200 mm. The two-stage injection unit comes with a 14- or 18-mm plasticating screw and a choice of three injection piston diameters. Shot capacity ranges from 0.4 to 1.7 cc or 0.4 to 1.7 g. Injection pressures are 2000 to 3000 bar (29,000 to 43,500 psi). The whole unit is mounted on a single-piece, water-cooled base plate. Overall dimensions are 78 x 39 x 81 in.

Several units have been sold in Europe and one to Nypro Inc., Clinton, Mass. Manner USA Inc. is in Lawrenceville, Ga. (maenner-group.com).

POWDER-METAL CAVITIES

In multi-cavity tooling programs for medical and other precision molding applications, key goals are exact uniformity and minimal cost in replicating cavities. Both goals reportedly can be satisfied by powdered-metal technology (PMT), in which the cavities are injection molded from a master cavity, using a mixture of metal powder and a small amount of plastic binder. Then, cavities are slowly “debinded” over a period of three to five weeks to obtain tight dimensional tolerances. Cavities can be machined after debinding.

Polyshot Corp., W. Henrietta, N.Y. (polyshot.com), is offering PMT tooling made by Israeli sister company Plasel Mold, said to be the largest moldmaker in the Middle East. PMT cavities are typically made of H-13 steel (though others are available on request) with feature tolerances down to 15 microns and cavity-to-cavity repeatability of less than 5 microns. Max. size is 70 x 30 x 25 mm. Cooling is typically through contact with a water-cooled mold base.

Advantages of PMT are said to include easy production of fine details and sharp corners, unique shapes that would be difficult or impossible by any other metalworking process, and short lead times to produce duplicates or spares.

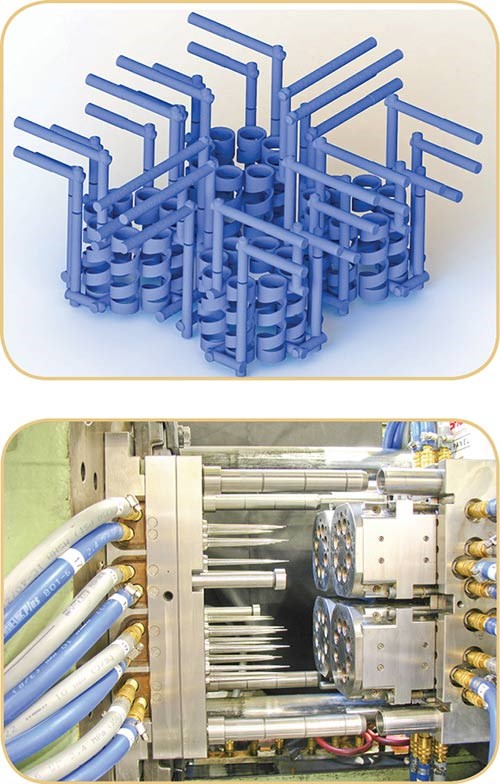

Together with Plasel, Polyshot is offering uniquely designed pipette tip molds with PMT cavities. These tools have 32 cavities arranged in four blocks, each block having eight cavities in a circular cluster. The 110-mm center distance within each cluster is the smallest in the world, according to Polyshot president Doug Hepler. Overall mold size is 300 x 386 x 305-355 mm, depending on tip length. Tooling is modular, so different tip lengths can be produced.

The cooling capacity in this mold is also said to be the highest in the world. The PMT cavities are inserted into precisely fitting cooling sleeves with spiral water channels milled on a multi-axis CNC lathe that rotates the part while it mills the grooves. The sleeves are in two halves and can be disassembled for cleaning. Thermal pins (heat pipes) are inserted into the core pins for internal cooling without risk of plugged circuits. Polyshot has a demonstration pipette-tip mold at its plant.

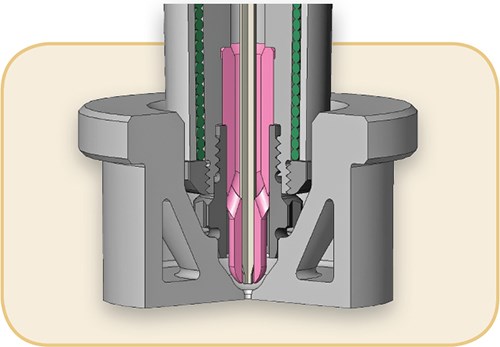

In addition, Polyshot has a new hot-runner nozzle (pinpoint or valve gate) suited to medical applications. Its latest Accutrak nozzle is designed to flush the insulating well completely on each cycle, eliminating stagnant melt and resulting burn marks at the gate, which can occur with materials like PC and acetal.

Related Content

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

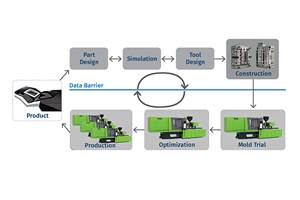

Read MoreInjection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More