Plastics Processing 'Jumps' into New Year

While still in contraction mode, the index came in at highest level since March 2023.

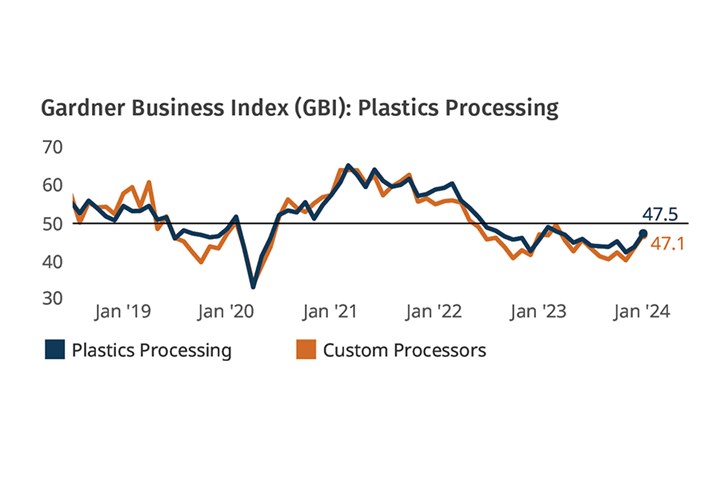

Looks like a new year does plastics processing activity good. The Gardner Business Index: Plastics Processing contracted in January to 47.5, but that number represented the highest the index has been since March 2023, and came in 3.5 points over December.

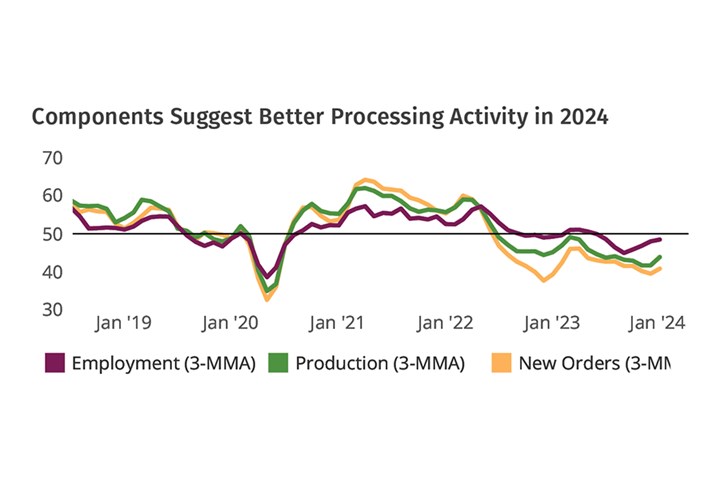

The results were driven by slowed contraction among a number of key components: notably new orders, production and employment. In addition, business optimism grew for a third month in a row, lending confidence (at least real hope) that recent trends may “stick.” A leveling of increasing material prices likely contributed to that optimism.

FIG 1 Plastics Processing activity continued to contract in January despite making great strides in slowing that contraction during January as well as the month before. The same is true for custom processing activity.

Exports continued on a steady path of contraction while supplier deliveries hovered around 50 (flat, meaning that as many processors see supplier deliveries taking longer as see them coming faster) like it has since September 2023.

Business activity for custom plastics processing changed almost the same, slowing contraction to the tune of 3.4 points in January following a 3.2-point dip in December 2023.

FIG 2 Components, new orders, production and employment, all marked notable slowing of contraction to start the new year.

ABOUT THE AUTHOR: Jan Schafer is director of market research for Gardner Business Media, parent company of both Plastics Technology magazine and Gardner Intelligence. She has led research and analysis in several industries for over 30 years. She earned a bachelor’s degree in psychology from Purdue University and an MBA from Indiana University. She credits Procter & Gamble for 15 years of the best business education. Contact: 513-527-8952; jschafer@gardnerweb.com.

Read Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)