Platy Mineral Filler Does a Better Job In HFFR Cable Sheathing

Greater flame and smoke suppression, lower heat release, and a more stable char—all at an economical price.

U.S. compounders of polyolefin HFFR (halogen-free, flame-retardant) cable coatings are starting to learn what is already well known in Europe and Asia: that a special mineral filler provides better flame retardancy and smoke suppression, as well as an unusual degree of mechanical reinforcement, compared with precipitated alumina trihydrate (ATH). What’s more, this naturally occurring mineral is more economical than synthetic ATH or magnesium hydroxide (MDH).

Those are some of the advantages claimed for its UltraCarb flame-retardant filler by LKAB Minerals in Sweden, whose U.S. office recently moved from Cincinnati to Chicago. At a user seminar last spring, presented by compounding machinery builder FARREL POMINI, Ansonia, Conn., LKAB Minerals discussed a new grade of UltraCarb and the latest developments in compounding this filler on the Farrel Pomini Compact Processor (CP), a two-stage combination of a Continuous Mixer and a single-screw discharge extruder.

FLAKY HYBRID MINERAL

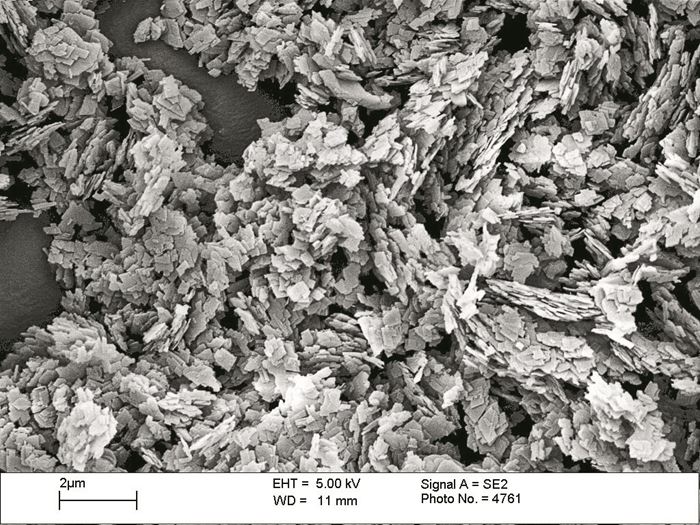

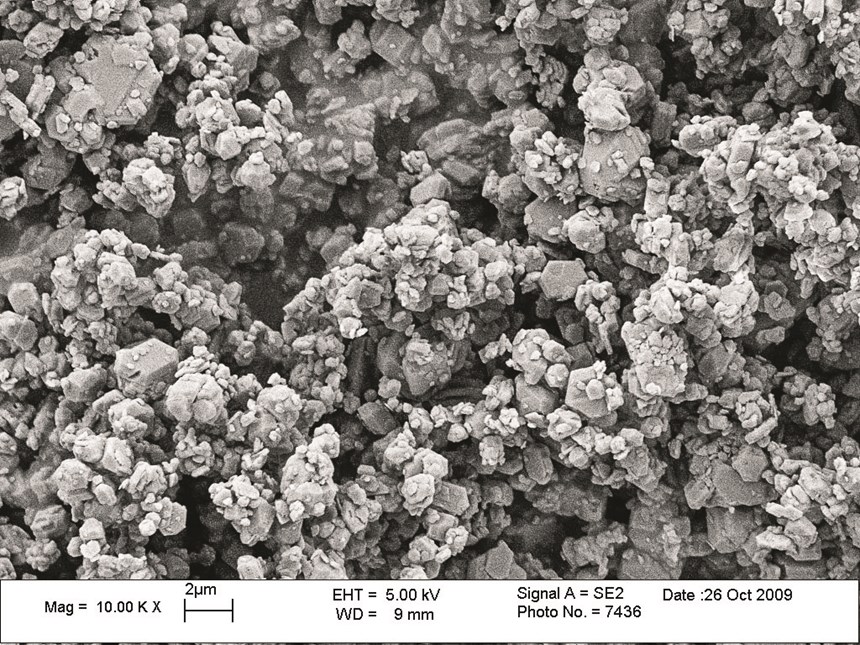

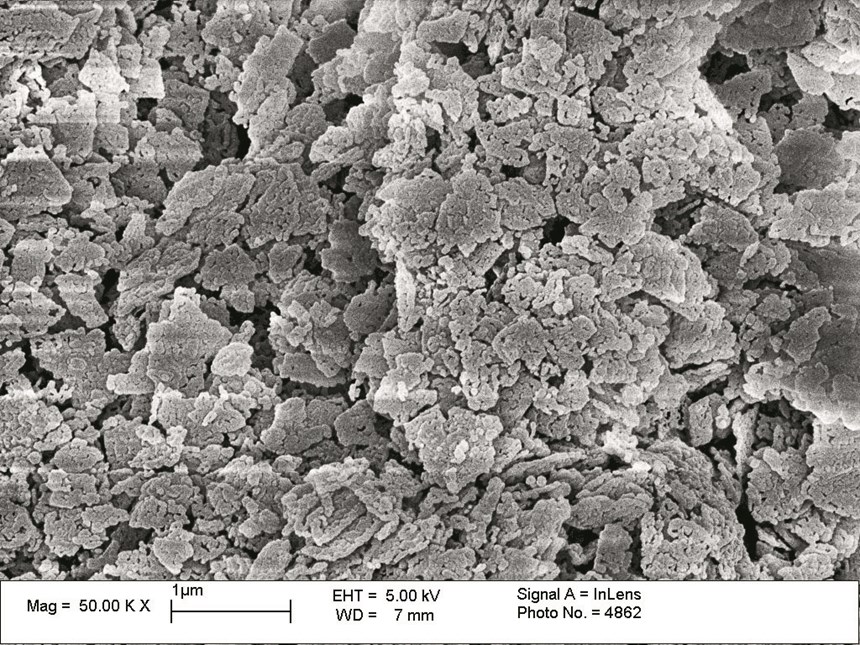

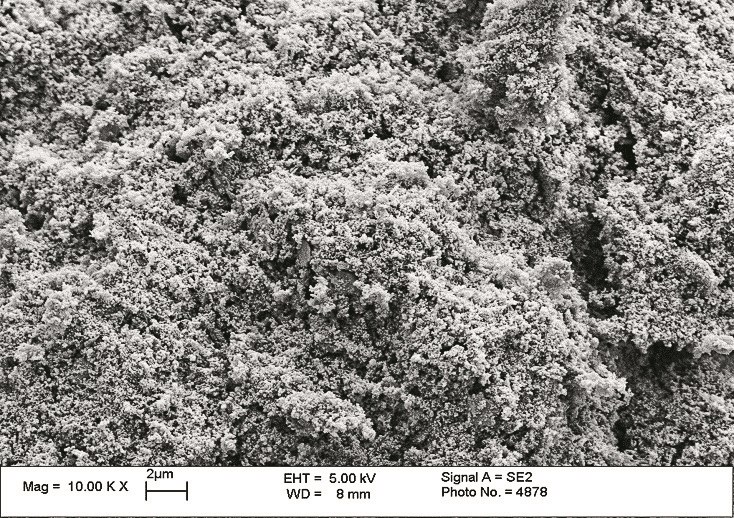

UltraCarb is a multifunctional hybrid of two minerals from a natural deposit: hydromagnesite (hydrated magnesium carbonate) and huntite (magnesium calcium carbonate). Together they are referred to as HMH, a platy mineral composite that gets its distinctive particle form from the huntite platelets, which are said to offer reinforcement (tensile-strength improvement) not provided by the more spherical ATH particles.

Questions about additives? Visit the Additives Zone.

This filler, which is better known in the North America for use in PVC and rubber, provides three-stage flame retardancy and smoke suppression. In the first stage, between 220 C/428 F and around 440 C/824 F, the hydro- magnesite releases water vapor. In the second stage, from 440 C to 600 C/1112 F, the huntite releases carbon dioxide (CO2). In the third stage, up to 750 C/1382 F, some CO2 evolution continues, but the main FR effect is char stabilization. The UltraCarb platelets retain their form in a stable, cementitious char, unlike the fragile char (similar to cigarette ash) that occurs with ATH, according to LKAB. Together, H2O and CO2 constitute 53% by weight of UltraCarb.

Another benefit of UltraCarb is that it allows use of higher melting-point polymers than does ATH, which gives up all its water below 200 C/392 F, or MDH, which decomposes at around 300 C/572 F.

Particle size of UltraCarb is described as similar to that of precipitated ATH: The platelets are 1-2 micron diam. and 50 nm thick. Their color is described as “very white,” and stearic acid or proprietary surface coatings are available.

According to LKAB data, 60% UltraCarb in EVA provides a 25% reduction in total heat release (THR) compared with 60% ATH in the cone-calorimeter test. In flexible PVC cable sheathing, 50 phr UltraCarb can provide much lower smoke density by ASTM D2843 and similar LOI, compared with an equal amount of ATH. Smoke density also can be much lower than for a formulation with 5 phr antimony oxide and 45 phr calcium carbonate.

PROCESSING TESTS

Within the past year, LKAB has worked with Farrel Pomini on testing HFFR compounds with up to 61.3% of the newest UltraCarb grade (LH3), which has finer particle size, in EVA on a CP550 machine. Using a #15/7 rotor configuration, the machine was able to process up to 225 kg/hr (495 lb/hr), or 350 kg/hr (770 lb/hr) with stearic-acid-coated UltraCarb LH3/C. LKAB says up to 65% UltraCarb can be processed without foaming or degradation and with homogeneous dispersion.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreGraphene Masterbatches for Flexible and Rigid Polyolefin Packaging and Beyond

Brazilian start-up Gerdau Graphene joins a growing group of graphene additives suppliers with a focus on boosting properties of large volume commodity thermoplastics.

Read MorePFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

(2).jpg;maxWidth=300;quality=90)