Prices of All Resins Surge

Despite a faster-than-expected recovery from Hurricane Harvey, the industry still faces challenges on the way to ‘getting back to normal.’

With the exception of PVC, September prices of large-volume commodity resins—PE, PP, PS, and PET—all surged, and October prices for all five resins were expected to move even higher. These elevated prices were linked directly to the impact of Hurricane Harvey on production of resins and monomers.

This is despite the fact that industry sources cite a faster recovery than originally through possible—both in terms of production restarts and transportation logistics. However, prices remain high because of snug supplies. The question remains:

How long are these elevated prices likely to last?

These are the views of purchasing consultants from Resin Technology, Inc. (RTi), Fort Worth, Texas (rtiglobal.com); CEO Michael Greenberg of Plastics Exchange, The in Chicago; and Houston-based PetroChemWire (PCW).

PE HIKES MULTIPLY

Polyethylene prices moved up another 4¢/lb Oct. 1, following the 3¢ September increase, and several suppliers announced an additional 3¢ hike for Oct. 15. Mike Burns, RTi’s v.p. of client services for PE, expected that third price hike to stick. He, for one, expects upward pricing pressure to the end of the year, and that price increases in place would hold firm into early 2018. PCW reported that one HDPE supplier moved the third increase to Nov. 1.

Addressing the impact on the PE market 30 days after the hurricane, these industry sources characterized supply as constrained; they expected that things would smooth out by the first quarter of 2018. “All three of the August new PE plant startups are now producing resin,” said Burns. “Dow’s, ExxonMobil’s, and CPChem’s new plants will help speed the recovery from Harvey and offer additional capacity in 2018.” He added that demand is pretty good, though there were difficulties in obtaining certain HDPE grades and hexene LLDPE.

The Plastics Exchange’s Greenberg reported at the end of September that spot PE prices eased by 1¢/lb overall, except for injection-grade HDPE, which “was super-scarce even before the storm.”

Also likely to be tight for the remainder of the year is blow molding HDPE. “Even though most reactors are back up and running,” he said, “the lack of production crimped availability, especially with some planned maintenance projects currently underway.”

PCW reported that crate injection-grade HDPE availability was improving, partly because HDPE producers were devoting more line time to homopolymers amid hexene-comonomer shortages. “Among film grades, LDPE clarity and extrusion coating was the tightest, along with hexene LLDPE—all products that are supplied by CPChem’s Cedar Bayou plant, now expected to be shut until late fourth quarter.”

PP PRICES COULD STABILIZE SOON

Polypropylene prices moved up generally by 7¢/lb in September, in concert with propylene monomer contracts. Suppliers were aiming to get a 3¢/lb margin increase above the monomer increase, but this did not seem to have occurred in most cases, according to Scott Newell, RTi’s v.p. of PP markets. He expected another increase of 2-3¢/lb, maybe more, based on proposed October monomer contracts: “That 3¢ margin increase is still out there, and with things being on the tight side for both monomer and PP, there’s some potential for that increase going through.” Still, he ventured that by November, PP prices would top out or even drop a bit, owing to some demand destruction from higher prices.

PCW also said suppliers’ margin increase was being spread over a couple of months. PCW reported flat to higher spot prices for PP and very tight availability of most grades. Yet it also noted that PP supply concerns appeared to be waning, and that talk in the industry was of a return to normal market conditions by November: “Higher-melt injection molding grades were in the tightest supply, particularly impact and random copolymers, while low-melt products were relatively balanced.”

Greenberg saw prices “poised for further gains, as resin supplies are still short, monomer remains tight, and production costs keep climbing. There is already a few cents’ cost-push increase that seems imminent for October; and producers, who have finally expanded margins with a successful increase, will likely leverage the upward momentum and soon nominate an additional increase.”

PS PRICES GOING HIGHER

Polystyrene prices, which moved up 3¢/lb in September, were expected to rise a bit farther in October, as suppliers sought another 3¢ hike, according to both PCW and Mark Kallman, RTi’s v.p. of client services for engineering resins, PS, and PVC.

However, only half of that increase would be justified by market conditions, said, Kallman, since both benzene and ethylene prices did not go up as much as anticipated and demand faces a seasonal slowdown. He noted that ethylene contracts for August and September would likely settle a total of 3-5¢/lb higher, while spot prices are dropping. Benzene prices in October settled 10¢/gal higher at $2.72-2.74, but spot prices were dropping to $2.64¢/gal. Kallman ventured that November PS prices would be flat or lower.

PCW reported that while spot PS prices held steady at September’s end, higher offers were expected for October as suppliers sought another increase. PS import availability was somewhat reduced by tight styrene monomer supplies overseas.

PVC PRICES MOVING UP—BUT HOW MUCH?

PVC prices were flat in September, but suppliers all announced a 5¢/lb price increase for October. RTi’s Kallman noted that the potential August-September ethylene contract settlement with a 3-5¢/lb increase would support only a 2.5¢/lb PVC increase. This, along with a decline in PVC exports, led him to venture that an October PVC hike of 2.5-3¢/lb was more realistic.

“What happens in November depends on how much suppliers get from the October increase. Unless they only get 1¢, I see prices for November-December as flat or lower.” Addressing demand, Kallman noted that while the hurricanes cut into housing starts in Texas and Florida, the flip side is the need for rebuilding. Thus, PVC demand could hold at a higher level than is typical for off-season.

Although most producers of PVC and key feedstocks were back on line, PCW reported that Formosa’s plant in Point Comfort, Texas, continued to operate at reduced rates, and the company’s force majeure was expected to last into mid-October. Meanwhile, OxyVinyl’s VCM and PVC units in Texas were working at full rates, though those in Pedrickton, N.J., and Niagara Falls, Ont., were not.

PET PRICES SURGE

Domestic bottle-grade prime PET prices in September averaged 65.5¢/lb, up 9.3¢ from August, based on PCW’s Daily PET Report. Truckload business is typically 2-5¢/lb higher than railcars. On Oct. 5, the PET price was 71¢/lb.

Meanwhile, September prices of imported prime PET, with an IV of 78 ml/g or higher, averaged 58.4¢/lb, up 4.5¢ from August. The price on Oct. 5 was 62¢/lb. Prices rose due to the shutdown of work at the “Jumbo” PET plant under construction at Corpus Christi, Texas, by M&G Chemicals, and to an anti-dumping petition filed on Sept. 26 against U.S. PET imports from five countries. The Jumbo plant is about 85% complete but work is at a standstill, with no indication of when it might be completed.

Related Content

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

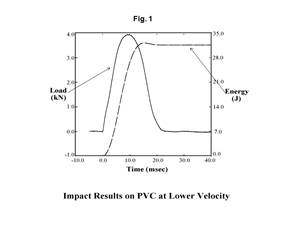

Read MoreThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

(2).jpg;maxWidth=300;quality=90)