Random Color-Infused Masterbatch Boosts Demand For Molded Mini Discs

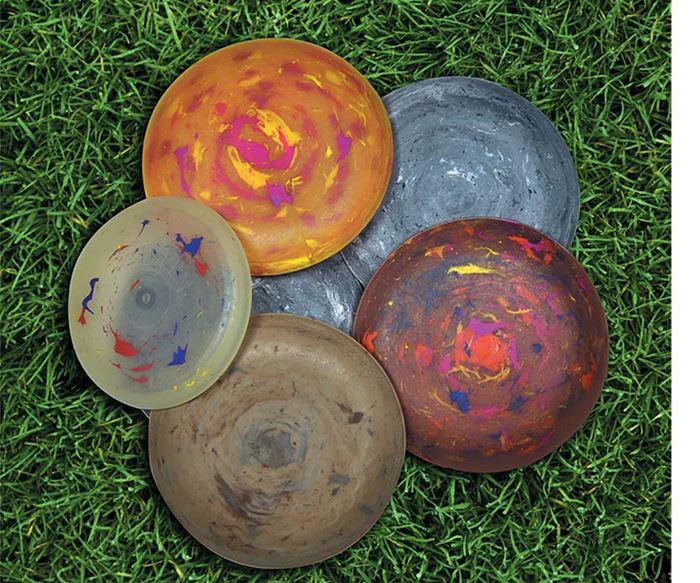

Zing Mini’s colorful new lineup allows mini-disc golfers to have unique discs.

Zing Mini, an eight-year-old startup company in Fishers, Ind., headed by mini-disc golf enthusiast and seasoned plastics engineer Craig Myers, has expanded its lineup of injection molded mini discs to include not only more colorful ones but those for players who want something just for themselves.

Mini-disc golf is an offshoot of Disc Golf—with a size difference. The small discs require a much smaller course—two to three acres for nine holes, compared with the 40-50 acres required for a regular disc golf course. The rules are similar to golf: Instead of holes, the discs are thrown into 3-4 ft tall wire baskets. The typical hole length ranges from 150 to 700 ft, with different discs often used for drivers, mid-range play, and putting.

Ranging in size from 3.75 to 4.5 in. diam., Zing Mini’s product lineup includes: Aerofoil, the largest disc, with a throw distance of more than 250 ft; Microfoil, popular for indoor use, as a course marker, and as a promotional item; and Cozmo, a mid-range and putter disc, dubbed by Myers the “competitor killer.”

Myers has more than 25 years of industry experience in automotive, medical, and consumer markets. For his latest innovation, he opted for the Carnival special-effects colorant from Ampacet Corp., Tarrytown, N.Y. This masterbatch is one among the FusionFX line of masterbatch four-color palettes for polyolefin consumer products, launched in late 2015, that use proprietary technology to produce random flow of color effects.

With Carnival, Myers can infuse random brightly colored confetti into his discs, with each one distinctly different as the color disperses randomly in a swirl pattern. Batches might include multi-colored flecks within a clear- or solid-color disc, and Myers has also added Carnival colors to black discs. “Our disc golfers are crazy about colors and they love having unique discs,” says Myers.

According to Myers, the initial inventory of the new random- effects discs quickly sold out online and through social media. This prompted him to produce custom minis that can be hot-stamped with names and logos for use in promotions or as wedding favors. Now, he’s innovating further with 2.5-in. discs that can be used as tags for disc bags and soda-can toppers or “soda savers” as promotional items for disc-golf enthusiasts.

Myers has been using a 1981 Arburg 221E, 77-ton toggle horizontal molding machine that he acquired from a lab, and more recently bought a 1993 200-ton Toyo press. He’s running a 0.913 density EVA because it’s very clear and can run at very low temperatures—220 F maximum. He has used metallocene elastomers that provide extra clarity and flexibility for his higher-end discs. “The EVA is a very friendly material—slightly rigid but also offers flexibility and good gripping characteristics,” says Myers. Moreover, Myers says FusionFX masterbatch is easy to process. “I have turned down my backpressure so that it will disperse optimally as it does not disperse in the barrel. Rather, it blossoms when it hits some shear in the gate that enters the mold cavity.”

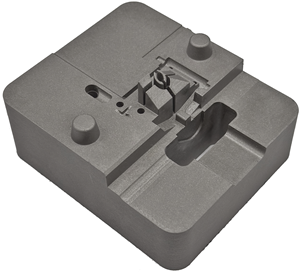

Myers has also been innovating with 3D printing equipment, starting with a MakerBot and then moving to a Flash Forge FDM Creator, which allows him to use ABS, PLA, and PEI. He has used the latter to make the cavity and core used in molding the Cozmo mid-range and putter discs. He has also used FusionFX with 3D printing as a subcontractor for production of new sporting goods such as flying tubes, as well as pet items.

Related Content

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More