Servo Robots Show More Speed, Muscle & Brains

The recent NPE 2009 show in Chicago saw the debut of dozens of new and enhanced robots for injection molding. The vast majority of the new models were all-servo types, though some economized by mixing servo and pneumatic axes. These new robots emphasized higher speeds, heavier payload capacity, longer reach, and more intelligent controllers that make programming and troubleshooting easier than ever. Telescoping arms and dual arms were very common among the new entries, as well.

ALL-SERVO TRAVERSE ROBOTS

Dri-Air Industries is the newest robot supplier, now the exclusive representative for the Americas of all-servo, three-axis robots from Sytrama of Italy. Described as rugged, easy to program, and competitively priced, the Sytrama G Series comes with payload capacities of 11 to 154 lb for use on presses from 40 to 4500 tons. Larger models have a telescoping vertical axis. The SCP controller is a handheld pendant with color touchscreen. Options include wrist actions and EOAT quick-change plates.

At the show, Dri-Air attracted particular attention with a novel Sytrama robot having a wrap-around beam design that allows the robot to perform three-axis functions using only two servo drives and thereby saving weight, size, and cost. The new and patented Unique robot, designed for presses up to 300 tons, travels along a beam with a rounded 90° curve, so that it makes a seamless transition in one smooth motion from the traverse stroke to the strip stroke and vice versa. Programming is simplified by having only two axes to define positions and movements. The controls are mounted on the compact frame. Price is around $18,000, or about 20% less than a comparable three-axis servo robot.

Hyrobotics showed a new automatic tool-change system and control pendant on a Nexia series servo robot. The Nexia series for presses from 50 to 4000 tons comes in single-arm (three-axis) and double-arm (five-axis) versions with two-axis servo wrist. The new HyTouch 57 handheld control pendant with 5.7-in. touchscreen is Windows based and has new and enhanced tool-change and EOAT functions.

Ranger unveiled its RT100 series of high-performance three-axis robots with a “fully teachable” TS controller and a “carriage front” design that avoids interference with equipment mounted atop the machine. The all-servo unit is designed for small parts and medical molding.

Ranger also now offers a complete manufacturing cell for low volume IML applications. The retrofittable system includes a static charger, wand, tooling, and robot.

Ranger’s president Fidel Ramos announced that Automated Assemblies has been restarted as a robot maintenance, repair, and refurbishing business of Ranger.

Sailor added a new high-speed servo robot with three or five axes of motion to its lineup. The RZ-200VE series is suited to presses up to 220 tons. It boasts positioning accuracy within 0.1 mm and payload capacity of 26.4 lb. Dry-cycle takeout time is 0.8 sec.

Sepro expanded its Axess line of affordable three-axis servo robots for simple pick-and-place applications with a new Axess 7 model for presses up to 80 tons. Sepro also reconfigured its Axess 11, 22, and 33 models with 33% greater vertical reach for presses up to 700 tons. Telescoping arms are offered with the Axess 22 and 33 models. The Axess line has the new Touch 2 control, which provides simple pick-and-place programming along with a 10-in. color touchscreen, and a joystick to steer the robot during programming. The joystick helps focus the operator’s attention on the robot, not the pendant, Sepro sources note. They also point out the on-screen documentation of the new controller, which includes the entire user manual and programming manual, as well as a “Frequently Asked Questions (FAQ)” section that finds the place in the manual that provides the answers. In case of an operating error, the touch of a button finds the manual’s description of the error message. Users can upload or download information via Ethernet, USB stick, or Wi-Fi.

All these functions and more are provided in Sepro’s new Visual 2 controller for its more sophisticated Generation IV beam robots. Three programming modes range from simple pick-and-place templates to freely programmable templates with lead-through teaching or direct programming (with the pendant or off-line) of complex routines. The PLC core of the system has standard scan rates of 100 millisec, but an optional Automation Pack speeds that up fivefold to accommodate stacking, insert loading, fabric overmolding, in-mold labeling, and post-mold fixturing and finishing. It can even manage intelligent peripherals like vision, barcoding, and RFID readers. Programming is facilitated with a Windows-based PC editor/monitor.

Star Automation introduced a line of telescoping-arm, high-speed robots for presses from 250 to 720 tons. The SAII series has Star’s STEC-380 controller in a simpler style with fewer options (i.e., no touchscreen), which makes the line about 15% more economical than Star’s VI series. Max. payload is 22 lb. The SAII-S version adds an additional sprue-picker arm to the carriage.

The latest from Wittmann Battenfeld is a five-axis, dual-arm telescoping robot for stack molds on presses up to 440 tons. The new model W823D delivers independent control of each arm for simultaneous or sequential removal of parts from stack molds, including family molds where parts have different design and handling requirements. The vertical telescoping arm is available with 1000- or 1200-mm stroke and a choice of three speed settings based on payload (standard, high-speed, or ultra-high-speed servo). The robot handles two payloads of 6.6 to 22 lb each, depending on the speed package. The model uses Wittmann’s brand new R8 control with color LCD.

Wittmann Battenfeld showed a single-arm W823 servo robot completely integrated into the frame of a Wittmann Battenfeld 270-ton HM press. The safety gate was extended to include safety guarding around the robot and indexing parts conveyor. The press controller can run the entire cell, though the robot’s teach pendant also can be used to set up downstream equipment. The cell was intended to show a fully integrated solution under one control and from one supplier. All elements could be operated and diagnosed remotely by Wittmann Battenfeld via the internet.

The company also introduced a smaller servo B-C wrist for smaller robots sized for 40- to 250-ton presses.

As we reported in July, new software functions on Wittmann’s new R8 robot control include SmartRemoval, which determines the fastest possible movements in and out of the mold—even starting robot motion before the mold is open. EcoMode function does the opposite for long cycles—slowing the robot down to use all the mold-closed time and save wear and tear.

Yushin introduced its RCII series of servo-driven robots for 80- to 650-ton presses. Increased rigidity allows take-out times at least 10% faster than with the RAII series, while the improved belt drive lowers wear and extends belt life. New linear bearing design allows main-arm stroke lengths to be extended up to 1600 mm, vs. 1100 mm previously. A new compact servo wrist allows for use in tighter spaces. “Eco” operating modes have been added to reduce electricity and compressed-air use (the latter by more than 33%).

Meanwhile, Yushin’s workhorse RA and RAII lines of robots have been adapted for packaging and general automation applications. They come with floor-mount pedestals and Windows XP-based controllers that can interface with the internet for remote monitoring and troubleshooting. They also interface with upstream and downstream automation without need for additional PLCs or controllers. Ability to track moving conveyors in order to pick and place parts on the fly is standard.

PNEUMATIC ALTERNATIVES

Though servo robots grab most of the headlines, economical models with mixed servo and pneumatic axes continue to improve. Wittmann Battenfeld rolled out new servo-pneumatic robots with telescoping pneumatic arms for use in low-clearance areas. W710 T and W710 TS (telescoping sub arm) units are for presses up to 200 tons. Fixed pneumatic kick stroke prevents collision with other devices. The servo-driven Z axis has 1500 or 2000 mm stroke lengths. Pneumatic wrist with 90° rotation is standard. The robots use the SA7 control and LCD graphical interface.

A new line of servo-pneumatic robots for presses from 50 to 350 tons was unveiled at the show by Yushin. The ATC/ATCII series has servo-driven traverse and pneumatic vertical and kick strokes. Traverse stroke (1100 to 1900 mm) has been increased for use with extended drop zones. Lubrication-free bearing design reduces maintenance. The new fully-programmable handheld GII controller has a large LCD screen that displays only the icons or features that are available at any one time to enhance ease of use. The series is a variation on the ATB line, which was not fully programmable.

SIDE-ENTRY UNITS

NPE was the North American debut of a new high-speed side-entry robot from Hekuma GmbH (represented here by Autotec) that trims mold-open time by 20% due to higher acceleration. The Heku 3 delivers 60% higher acceleration than the previous model and is designed for applications from high-cavitation jobs with sophisticated EOAT to vacuum testing or complex assembly and insertion tasks. Heku 3 has enhanced drives that transmit higher torque directly to the shuttle drive, and linear guides that allow high transfer speeds. Heku 3 is said to deliver acceleration up to 100 m/sec2, and transfer speeds up to 7 m/sec with payloads up to 570 lb and repeatability to 0.0004 in.

Ilsemann says its new SM 700 side-entry servo robot has faster response and higher speeds than previous models. The compact unit is being used in IML applications in Europe, where it handles 12+12 lid or 6+6 container applications.

Ranger Automation introduced its SA-300 dual-arm side-entry robot for stack molds. It is designed to run at a 4-sec overall cycle. Also new is an in-mold decorating and labeling retrofit kit.

JOINTED-ARM & SCARA TYPES

In jointed-arm robots, ABB launched its IRB 400 six-axis model for assembly, packing, and palletizing. It comes in two short-arm versions with max. payload of 99 or 132 lb, and two long-arm versions with payload capacity of 44 or 88 lb. ABB’s new SafeMove safety software and electronics system, which allows the operator and robot to work in closer physical proximity, enabling layout of more compact cells by restricting robot motion to precisely what is needed for a specific operation, instead of relying on inflexible mechanical stops. This allows users to save money on safety equipment such as light curtains, safety relays, mechanical stops, position switches, and protective barriers. The software is integrated into ABB’s IRC5 controller.

Motoman also introduced a new Slim Individual Arm (SIA) series that features seven axes of motion and is intended for assembly and machine tending operations. Motoman offers the SIA10D model with 22-lb payload, 47-in. vertical reach, and 28-in. horizontal reach. Model SIA20D has a 44-lb payload, 59-in. vertical reach, and 36-in. horizontal reach.

They use the new DX100 controller, which can handles up to eight robots (or 72 axes) as well as I/O devices and communication protocols. Features include faster processing, smoother interpolation of robot movements, quicker I/O response, and built-in collision avoidance. Repeatability is said to be ±0.004 in. All operator controls are on a pendant. It has multiple window display capability and conserves power during robot idle time, which reportedly saves up to 25% in energy.

Motoman also introduced a new version of the 13-axis robot with dual jointed arms that it showed at NPE 2006. The new Slim Dual Arm (SDA) series has 15 axes of motion, including an added servo-driven C-axis wrist. There are seven axes per arm, plus an axis for base rotation. One arm can hold a part while the other arm performs tasks, or parts can be transferred one arm to the other without setting the part down. Each arm handles 22.1 lb. of payload. Horizontal reach is 35.8 in., and vertical reach is 71.7 in.

Reis Robotics unveiled its RVL six-axis, beam-mounted “hybrid” robot for injection molding. It handles payloads up to 286 lb.

Staubli introduced a new line of high-speed SCARA servo robots, suited to pick and place, material handling, packaging, assembly, loading, testing and dispensing applications. The three models (TS40, TS60, and TS80) have a reach of 400, 600, and 800 mm respectively, and a maximum payload of 17.6 lb. Staubli says this is a 30% increase in performance over the previous RS series.

Related Content

Five Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

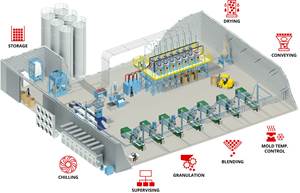

Read MoreA Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreAutomation Evolution: From Robots to Work Cells, Solo Devices to Integrated Systems

Injection molding automation has progressed from devices to systems, from simplicity to more complex capabilities. The author traces this development through various levels of automation – all still available choices today – and analyzes the costs and capabilities for each level.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

(2).jpg;maxWidth=300;quality=90)