Shots for Shots: Canon’s Shuttle Mold Doubles Up Molding of Glasses and Carrying Case

NPE2024: Updated shuttle mold, imaging and engraving technology, and moldmaking capabilities on display.

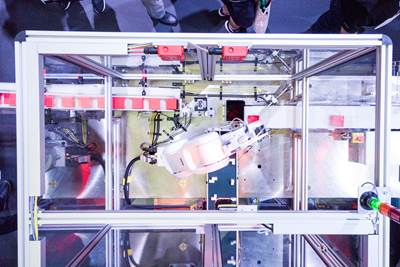

Canon Virginia is showing NPE visitors how it has updated its Shuttle Mold system via a unique display and giveaway. The technology enables one machine to run two molds at the same time by shuttling tools in and out of the press to alternate between injection and part cooling, converting normal downtime of mold cooling into production time. Visitors can see the system in action at Japan Steel Works’ (JSW) booth running on a 350-ton JSW machine.

Molding in optically clear SMMA, the two molds shuttling in and out of the JSW machine are molding four shot glasses in one four-cavity tool and a clear container for the glasses in the other. The container’s lid flips over, creating a space to stage the glasses in a flight. The glasses themselves are engraved with a four seasons theme via a proprietary Canon technology.

“At this NPE, we are trying to take full advantage of the event,” says Wayne Daniel, Canon’s director of business development. “In addition to showing some of our capabilities, we have formed some collaborations with partners to have our technology in their booths, which allows us to expand our space.” Canon is also taking advantage of NPE’s educational platform, presenting from the Innovation stage on May 8 at 1 p.m.

With an eye on easier integration, including the possibility of retrofits on existing presses, Canon has updated the Shuttle Mold concept with enhancements that enable it to more easily integrate the system into existing presses.

Also, with the new changeover option, molders with numerous tool changes can group and run two similar molds in the same machine, using the shuttle system to hook up heating and water lines outside the press for a new tool which is shuttled into the machine — all without the normal downtime for removing the old tool, installing the new one and then waiting as it’s brought to processing conditions.

Canon is also highlighting its moldmaking capabilities, displaying some decommissioned tools in its booth that it fabricated in-house for internal Canon products, as well as showing its support for multiple markets with parts on display from various sectors.

The company is also showcasing some of its imaging technology — Vision Addition Software — which can be used to monitor analog gauges, a task the technology performs for Canon. One example is Canon’s fire suppression system, which it has throughout its Virginia campus. Featuring large, mostly analog gauges that must be checked, the technology uses imaging to view the gauges, sending information back to the central hub and then applying software to see live images of the software, which alerts to an out-of-range figure.

“In molding operations, or any industry,” Daniel says, “there’s usually a combination of new and old technology. The new technology might be digital and gives you a feedback loop, but the older tech is analog and someone still has to look at it.” Canon has also used the technology for some part inspections, as well as in automation, determining if a part is present and if it’s oriented correctly.

Head to JSW’s booth to see Canon’s Shuttle Mold System in action and pick up a slick giveaway to boot.

Source: Canon Virginia

Related Content

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreWhat to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreRead Next

Canon Virginia Graduates First Class of Apprentices

President Obama declared this week National Apprentice Week and in honor of that, employers across the country will host open houses to highlight the significant value of apprenticeships in our economy.

Read MoreCanon Virginia PTXPO Spotlight

Canon discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30

Read MoreInnovations in Molding, Machine Texturing, Micro-Fluidics and More at Canon Virginia Booth

Multi-Mold System shuttles molds in and out to run two separate tools in one press simultaneously.

Read More