Solutions to Batch Blender Issues Save Money & Downtime

When a blender is operating poorly, odds are that the fixes are quite simple if you know what to look for.

When a batch blender is operating properly, there are many things—both internal and external—that can have a positive effect on performance. When the blender is operating poorly, chances are that something has compromised the performance of one or more of these functions. Many of these issues are quite simple and you can save valuable time and money if you know what to look for.

Most gravimetric batch blenders use horizontal or vertical dosing valves that rely on gravity to move material. When these valves open, gravity pulls the material down through the valve opening and into a weigh hopper that determines the weight of polymer dosed and the flow rate while the valve is open. Several things have an impact on the way gravity affects the material and, thus, the flow rate.

In this case, the material itself—especially its particle shape—is the most likely problem. Particle shape, in turn, affects the bulk density of the material, which must be above 12 lb/ft³ (192.24 kg/m³) for most dosing gates. Irregularly shaped materials like regrind tend to bridge or flow inconsistently, so they need larger valve openings, flow-enhancing devices, or an auger feed system.

A second, less-well-known factor affecting flow rate is a poorly operating vacuum loader. If the dump valve on the bottom of the loader does not seal completely, it can leak air and place a vacuum on the dosing valve and material bin. Even a small amount of vacuum can affect material flow through the valve, and large vacuum leaks can fully suspend the material and prevent it flowing through the valve at all.

The next critical factor for proper dosing is the weigh system, which consists of a batch hopper suspended on a load cell. In this arrangement, the load cell must be properly calibrated, and it must also be tested for linearity across its entire weight range. Manual calibration using only a single weight supplies the load-cell computer with a tare weight reading (the weight of the empty hopper assembly itself) plus the calibration weight, but it does not test the load cell for linearity.

To test linearity, it is necessary to use three different calibration weights, including two weighing more and less than the original calibration weight. If the load cell is properly linear, the computer will display a correct reading for all three weights used in the test.

check the mixer level switch

Once we have a properly loaded blender, with materials that flow correctly, and a properly calibrated load cell, the next thing to look at is the mixer level switch. Most batch blenders have a level switch in the mixing chamber to tell the control that there is enough empty volume in the mixing chamber to accept another batch from the weigh hopper above the mixer. There are two conditions that may cause the mixer level switch to malfunction.

First, if the switch always detects that the mixing chamber is full, the computer will stop allowing new batches to enter the mixing chamber and the process will become starved of material. This condition is most likely caused by fines and dust that build up on the sensor. If so, cleaning the lens of the sensor will solve the problem. It may also be that sensor settings need to be adjusted.

If, on the other hand, the switch is reading the mixer as always empty, this will force the computer to continually attempt to satisfy the demand. Of course if the mixer is actually full, there is no room for these additional batches to go. This condition almost always results from incorrect switch settings.

BLENDER DESIGN AND SPECIFICATIONS

This next group of problems has to do with the operation of the blender. When purchasing a blender, it is critical to specify the type of materials to be blended and recipe percentages of each ingredient, along with the maximum throughput rate required. The blender manufacturer needs this information to ensure that the openings in the dosing valves can handle the necessary volumes.

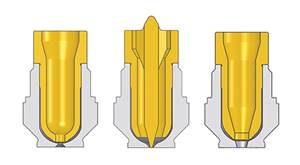

Valve size and geometry must be adequate to handle both the maximum and minimum percentages required for each ingredient and do so at the maximum throughput rate. Smaller valve openings are usually required to ensure accurate dispensing of extremely low dosing percentages, while large valve openings are required to achieve high dosing percentages at the desired rate of the process.

Once the blender is installed at the processor’s plant, operators should make sure the correct valve is used for each ingredient percentage. Using a small dosing valve for a high-percentage component will dose accurately but will limit the total rate for the blender. On the other hand, using a large dosing valve to dose a small-percentage minor ingredient will compromise dosing accuracy.

SPECIAL REQUIREMENTS FOR HIGH-TEMP RESINS

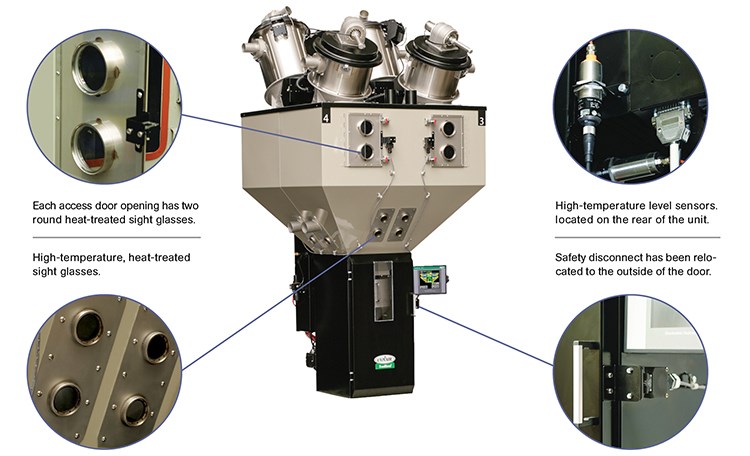

Finally, remember that a blender that will need to dose and weigh high-temperature materials will have specialized requirements. Most blenders with standard hardware components can handle materials at temperatures only up to about 160 F (71 C). However, processors that want to blend engineering resins after drying to prevent separation during drying and conveying will need a blender built to withstand the high-temperature stress.

When properly designed and built, blenders can easily withstand temperatures up to 375 F (190 C) or even higher. For medium-temperature (160-375 F or 71-90 C) drying of resins like ABS, nylon, and polycarbonate, look for high-temperature-rated air cylinders, hoses, and load cells, plus a power box that is isolated on stand-offs from the blender housing, and safety disconnects on the outside the body of the unit. When drying at 375 F (190 C) and above for polyesters like PET and PBT, add tempered glass in the hopper and mixing-section sight glasses.

The blenders can also be equipped to blanket the material compartments and mixing chamber with dry air to prevent moisture regain during blending. It is imperative that these requirements are known before the blender is delivered, because refitting a system after installation can be costly and time-consuming.

Not every blender problem is a serious malfunction. Often, it’s a simple matter related to operation or maintenance that can be resolved quickly by in-plant personnel. Knowing the causes of and solutions to these basic issues, you can avoid the cost and downtime associated with calling in a factory-service technician.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)