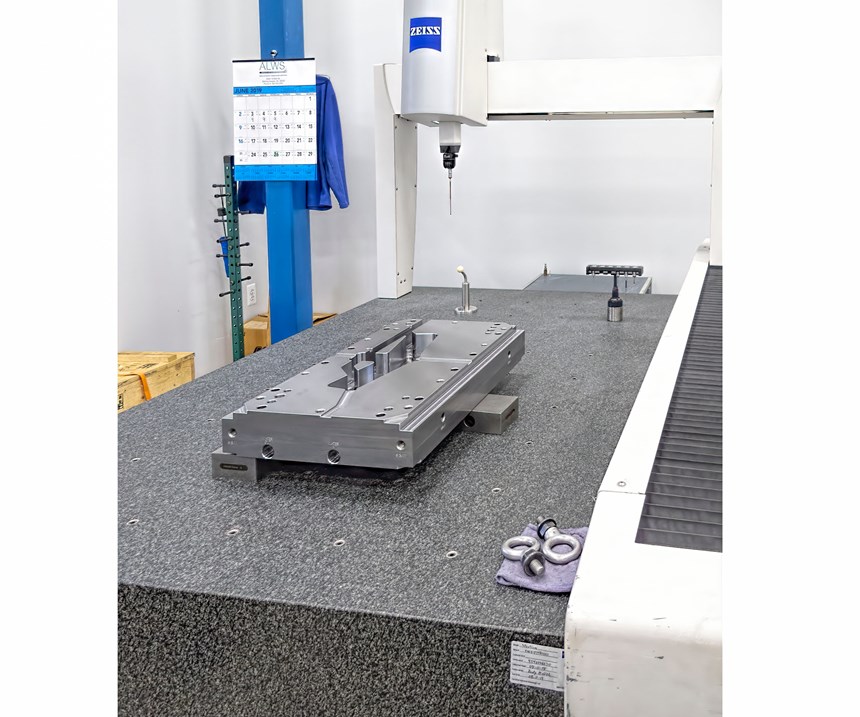

A Walk Around Incoe’s New Hot-Runner Plant

A private tour—the grand opening of Incoe’s new headquarters plant.

In early June, I had the opportunity to take a personal guided tour of the new Incoe headquarters plant in Auburn Hills, Mich., led by automotive business-development manager Jim Bott. The occasion was the official Grand Opening celebration of the move from the previous headquarters in Troy, Mich., which actually took place last August.

The 138,000 ft2 facility employs around 200 working two shifts, and is one of five Incoe manufacturing locations worldwide. The site has room for expansion by another 30,000 to 40,000 ft2. The factory is divided between production of standard hot-runner components and custom manifolds. According to Bott, the plant stocks 3100 different crib parts and 385,000 items in inventory.

Bott pointed out that CAD drawings, electrical schematics, inventory counts, and manufacturing orders are shared wirelessly throughout the plant. For example, 3D CAD files of components are converted to CNC machining code, which is transmitted to the lathes and milling machines.

Besides manufacturing, the new facility has 15 conference rooms and a training area. The latter has a lecture room that seats 40 and a machine lab with three KraussMaffei presses of 80, 200 and 550 tons. Two of those machines are equipped with Roctool’s induction-heating system for rapid heat/cool molding. Bott said the training area hosts two 8-hr sessions a week, on average, free to customers. Partners such as KraussMaffei, Roctool, Beaumont, RJG and Progressive Components also conduct training here.

Related Content

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

-

How to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

(1).jpg;maxWidth=970;quality=90)