Carbodeon Granted U.S. Patent for Nanodiamond-Containing Plastics

With thermally conductive plastics rapidly growing in demand, the addition of nanodiamonds to the arsenal of thermally-conductive fillers is only welcome.

Finland’s Carbodeon has been granted a U.S. patent for its technology which enables detonation-synthesized diamond particles –nanodiamonds (ND)—to be combined with polymers for use in fields such as consumer electronics, LED lighting, automotive and machine tools. The earth’s hardest natural mineral is also one of the most thermally conductive materials known, so when NDs are mixed in with thermoplastics in controlled amounts, they can enable plastics to conduct heat at pre-determined rates, and/or to be highly wear-resistant.

As we reported last year, the company is selling its ultra-dispersed” uDiamond ND fillers via U.S. representative SiliconSense of Nashua, N.H. Available in powder or liquid dispersions, the ND is reportedly fully dispersed into its primary particles without agglomeration. As such, the compounder and end-user can benefit from the entire available ND surface area, resulting in better performance with less material and cost.

ND-impregnated polymers can deliver heat-conducting benefits for products such as LED lighting, mobile devices including cellphones and Internet-of-Things (loT) enabled devices of any type. The hard wearing properties also make them ideally suited for use in the automotive and aerospace sectors to enable longer product life in hard-wear environments.

Carbodeon’s U.S. patent #9085723 is on the company’s developed nanodiamond containing thermoplastic thermally-conductive composites. The patent was filed after the company’s own developments during 2012-2013 whereby they discovered that the thermal conductivity of thermoplastics can be significantly enhanced by adding nanodiamonds, usually is relatively small quantities (e.g., 0.1%). Since filling the patent, Carbodeon has continued their own research as well as developing the range of commercial applications of the technology.

Said company CTO Vesa Myllmaki, “The granting of this patent represents a key part of our nanodiamond composite material portfolio. The combined coverage of our filed and granted patents will secure our position and that of our customers in several nanodiamond applications including polymers for thermal management applications, wear- and corrosion-resistant nanodiamond metal finishing, and wear-resistant/low-friction nanodiamond fluroropolymer coatings.”

A recently-released report, “Thermally Conductive Plastics Market by Raw Material, by End-Use Industry—Global Trends and Forecast to 2020”, by India’s market research firm Markets and Markets, projects a 14.3% annual growth of thermally conductive plastics over the 2015-2020 period. The report notes that thermally conductive plastics are used in a broad range of industries including electrical & electronics, automotive, industrial, healthcare, and aerospace. In 2015, the electrical & electronics segment accounted for the largest market share among all the end-use industries in terms of volume, followed by automotive, industrial, and healthcare. Among all the end-use industries, healthcare is estimated to grow at the highest annual rate.

Another interesting tidbit from this study is that rising demand from North America is the major driver for thermally conductive plastics. In 2015, North America is estimated to account for the largest market share in terms of volume, and is estimated to remain the market leader in the next five years. The use of shale gas as raw material for producing polymers has lowered the price of thermally conductive plastics and is boosting demand in this region. Within the last two years, the U.S. led the demand for thermally conductive plastics due to increased demand of LED lighting. Markets in emerging economies, such as Mexico, China, and India are projected to grow very rapidly.

Key companies profiled by this study are: BASF, Covestro, Saint Gobain, Toray Industries, DSM, Hella KGaA Hueck & Co., RTP Company, Celanese Corp., Polyone Corp., Kaneka Corp., and Mistubishi Engineering-Plastics.

Related Content

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

Read MoreLanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

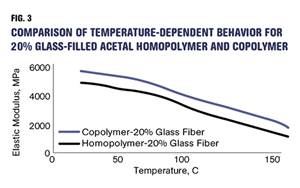

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

(2).jpg;maxWidth=300;quality=90)